5 Finishing Flaws Powder Coaters Don't Have to Accept

-

By

Lee Lechner

By

Lee Lechner - Aug 23, 2016

Have you ever been powder coating and experienced issues like overspray, re-tapping holes or paint flaking? More often than not, powder coaters are accepting flaws they could easily eliminate. We’ve curated a list of common issues powder coaters often overlook and provided simple fixes for each one.

Re-Tapping Threaded Holes

Having to re-tap threaded holes comes from incorrect or inadequate masking. Any time paint gets into holes and has to be re-tapped, labor increases, quality is at risk, and profits decrease.

How To Prevent Having To Re-Tap Threads

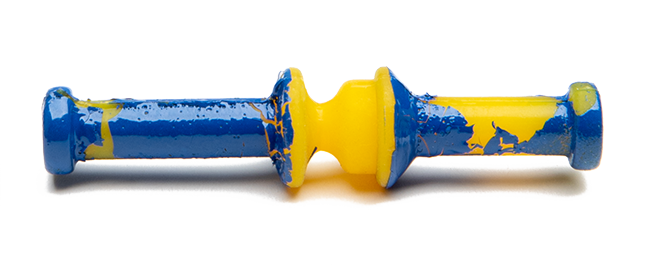

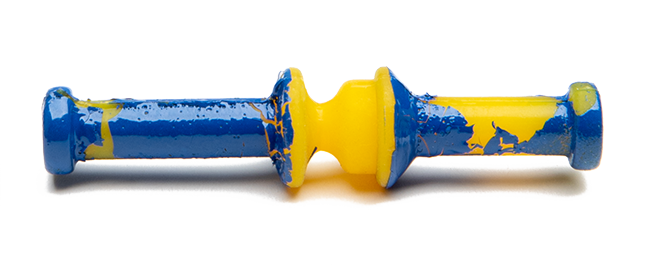

To avoid having to re-tap a threaded hole, your best option will be using a masking plug before coating. A push plug (like in the image below) will be the most ideal choice for threaded blind holes, while a pull plug works best for through holes. Whether masking a blind hole or a through-hole, creating a tight seal on the leading threads will be vital towards keeping all threads clean.

Overspray

Overspray usually happens due to issues stemming from masking choices, sizing, and application flaws.

Preventing Powder Overspray

If masking tape was used, make sure all surfaces to be masked are clean, dry and free of any debris that might keep the tape from adhering. Choosing the correct tape for the process and temperature is also critical. Incorrect tapes can cause it to prematurely fail prior to the paint process causing overspray issues.

If using a plug or cap for masking, choose a correct size plug. Need to mask off a spot face, but a standard non-flanged plug caused overspray? Use a correctly-sized flanged plug or flanged cap. If the flange does not seat tight to the face of the part, overspray can pass between the flange and the part being coated. Custom options can also help eliminate this issue as well.

Bridging (Powder Build Up)

Bridging happens when the paint/powder piles up against the mating point of the masking and metal that is being painted.

Preventing Powder Build-up

One option for reducing bridging is to create a feathering effect or try and take advantage of the Faraday Cage effect where the charge helps push the powder away from the area. Taper the parts so the edge is as small as possible.

One of the most efficient solutions to help reduce bridging is to implement a custom mask that provides protection around the grounding area of the transitional spot. There are several designs to achieve this protection, but a common solution is to design a mask with a flange wrapped around at an angle like an umbrella or a skirt. (See featured plug below)

Paint Flaking Off of Masks

Quality issues are caused due to paint sticking to masking materials and flaking off.

The Fix

Cleaning your masking caps and plugs will remove paint from previous processes, reducing your chances of having paint flake issues. A vibratory tumbler does this well.

You may also need to switch masking materials. Red iron oxide silicone can provide great results in place of virgin silicone material when used in high-temperature paint applications, such as powder coating or e-coating. The paint will bond better with this type of silicone.

Need help fixing these issues or want more information? Fill out the form below and request a consultation with our sales and engineering masking experts about what solution is best for you!