Basics of Rubber Shore Hardness

-

By

Lee Lechner

By

Lee Lechner - Apr 14, 2020

What is Shore Hardness?

Rubber shore hardness is the measure of the resistance a rubber material (like Silicone or EPDM) has to indentation, or quite simply, the hardness of the rubber. Understanding and modifying shore hardness of a rubber substrate is a vital element of meeting performance and quality specs in many of the rubber components used today.

Shore Durometer Measuring

The Shore durometer is a device for measuring the hardness of a material, like rubber. Hardness is defined as a material’s resistance to indentation. The higher the number, the greater the resistance of the material, meaning a harder overall material.

There are several scales of durometer, with the two most common scales being the ASTM D2240 Type A and Type D scales.

Shore A Scale

The Shore A scale ranges from 0A to 100A. 0A durometer molded parts would be very soft, while parts made using 100A duro rubber would be very hard. We typically deal with molded products that range from 20A (similar to the hardness of rubber bands) - 80A (rubbers similar in hardness to what you'd find on a shoe's heel), depending on the application.

For measuring Shore A, the device's configuration involves a 35° truncated cone that indents the material, while Shore D, on the other hand, penetrates the surface.

Shore D Hardness Scale

Shore D hardess scale is used to measure the hardeness of harder rubbers, semi-rigin plastics, as well as hard plastics.

How Does A Shore Durometer Work?

The way these devices work is a hardened steel pin is pressed down into the material sample. The pin uses a precision-engineered spring mechanism that exerts a constant force into the material.

When the pin is pressed into the material, it measures the hardness of the material's resistance to indentation under the force of the spring.

Shore Hardness - Sealing Applications

When it comes to using rubber in seals and gaskets, it's important that the material is soft enough to produce an effective seal that fills the gap between two surfaces, yet hard enough to withstand loading forces without extruding out. Below we give a little more detail about the difference between a door seal vs. standard o-rings.

Shore Hardness - NVH Applications

From a strictly in-cabin noise reduction perspective, rubber shore hardness comes into play in-regards to a higher shore rating means higher density. Rubber grommets and plugs with a higher shore hardness perform better at reducing the amount of noise that get through to the cabin due to its higher density and better ability to block sound. Below we give a few more details about basic automotive applications.

Rubber Hardness in Automotive Applications

Modern vehicles utilize a wide-range of Shore A rubbers, from softer to mid-range duros (40A-55A) used in door seals, gaskets, & masking caps/plugs, all the way to harder duros (60A+) use in panel plugs, grommets, rubber bushings, o-rings, and even tire treads.

Rubber shore hardness has become more important over recent years due to the increase in popularity of Electric Vehicles. OEMs, Tier-1s, & Tier-2s need to optimize every point that may impact in-cabin NVH. For rubber molders, this includes rubber components' density and shore hardness.

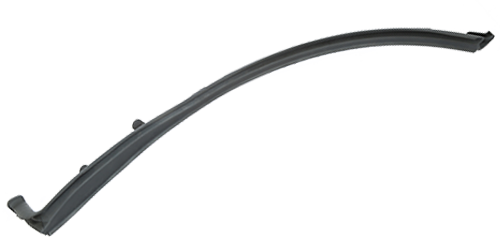

Sealing - Door Seals

Door seals are much larger and come in a variety of different materials, ranging from softer foams to mid-range rubbers (50A-60A+) and some are even made from thermoplastics, like TPV. This type of seal's durometer is going to be very dependent on the application and location.

MRO - Silicone Masking

Masking is about creating an effective seal. The key is in using a silicone material that is soft & flexible enough to conform to uneven surfaces like threads, while also hard enough to be molded & maintain its shape. Most silicone masks tend to range from anywhere as soft as 40A, up to around 55A.

NVH - Grommets & Panel Plugs

A good rule of thumb for better NVH performance out of rubber components is to have a higher durometer as it will improve NVH resistance due to higher density. Typically, you'll see grommets & panel plugs right around 60A-65A Duro.

Tires

Tires are going to be on the higher range of the Shore A scale as it needs to be stiff & durable to withstand the harsh conditions a vehicle's tires need to withstand. Most tires you see will be around 70A+ Duro.

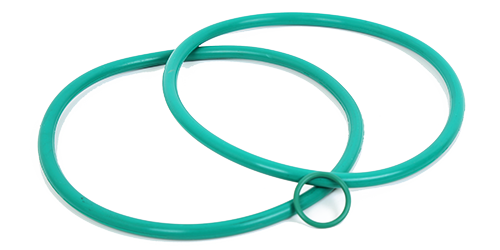

O-Ridngs

70A duro offers the best combination of properties for most o-ring as it offers greater abrasion resistance while maintaining its sealing capability in (sometimes) extreme applications. Most o-rings found in a vehicle typically range from 70A-80A Duro