Compression Molded Rubber Tolerances

-

By

Lee Lechner

By

Lee Lechner - Apr 27, 2022

A rubber part's tolerance has huge implications for masking and protection parts, where even the smallest fluctuation in a part's size can be the difference between a perfect fit and testing failure. In industries like the automotive world, tight tolerance requirements have become the industry standard, but what exactly does that look like when it comes to rubber parts?

In this post, we're going to take you through the basics of rubber part tolerances, the four tiers of dimensional tolerances defined by the RMA, and what factors affect rubber tolerances.

What Are Rubber Part Tolerances?

Also referred to as "dimensional tolerances" or "engineering tolerances", rubber part tolerances are the allowable size variations for rubber products. Essentially, the dimensions of a rubber part are given a value range.

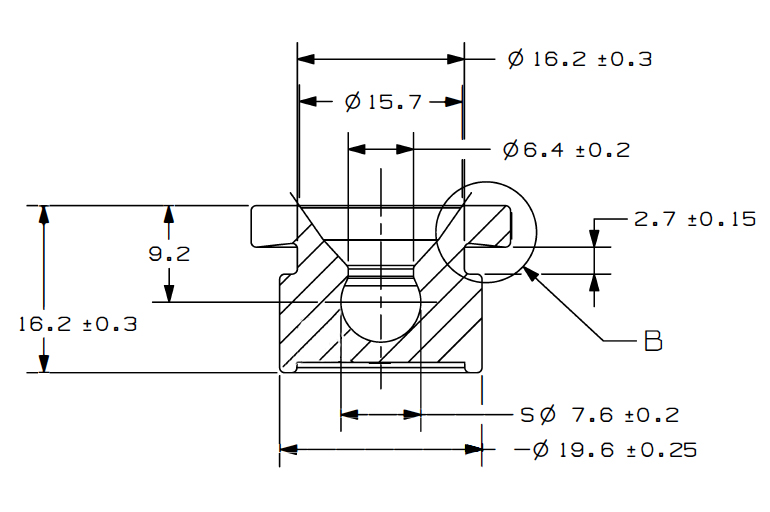

The two main dimensions you'll deal with are fixed and closure dimensions, so let's start there...

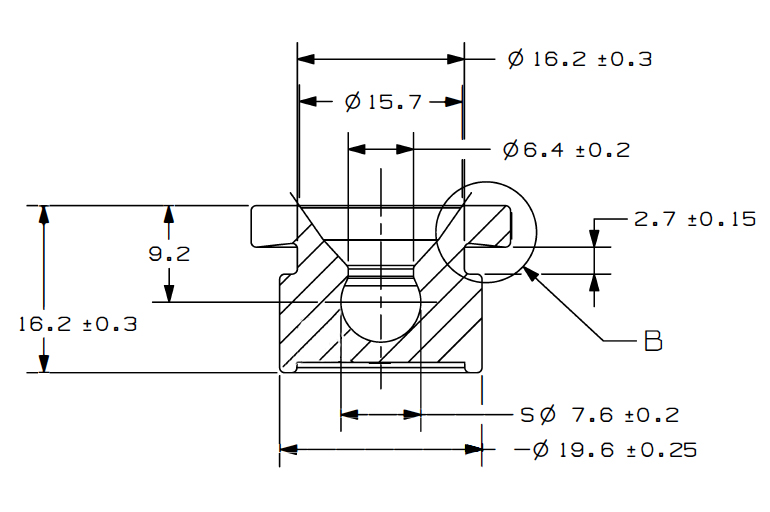

Fixed Dimension

A fixed dimension is everything that is machined inside of the mold's cavities (top and/or bottom plates). These dimensions are not affected by flash thickness variation.

Closure Dimensions

A closure dimension (also referred to as a closed dimension) is the dimension created when the top plate and bottom plate come together. These dimensions are affected by flash thickness variation.

The Four Tiers of Dimensional Tolerances for Rubber Products

When it comes to dimensional tolerances that are used for molded rubber products, there are four levels to select from:

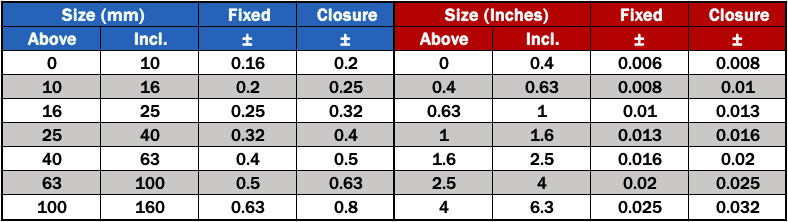

- A1 (High Precision) - This is the tightest tolerance of the four tiers. As you might expect, this tolerance requirement will be the most costly as it will require more expensive molds that will typically have fewer cavities (which will result in more time required to mold requested quantities) and require more quality-related process controls and product inspections. It's highly recommended that the exact method of measurement be agreed upon between the manufacturer of the molded part and the customer receiving the part.

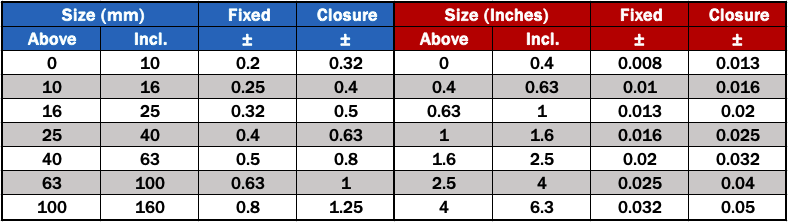

- A2 (Precision) - A2 indicates a precision-molded rubber product that requires a mold that is precision machined and kept in good repair

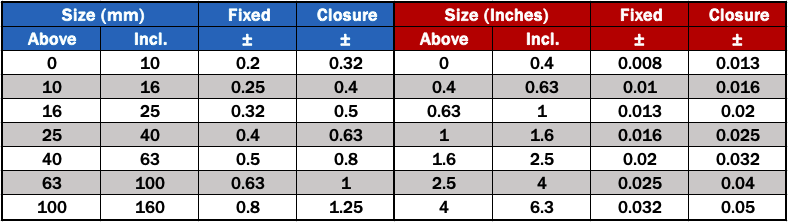

- A3 (Commercial) - This tier of dimensional tolerance is what you will normally see used for most rubber molded products. It's worth noting here that the majority of dimensions of a mold will be cut to this standard. Even molds with A2 & A1 tolerance requirements will most likely still include mainly A3 tolerances.

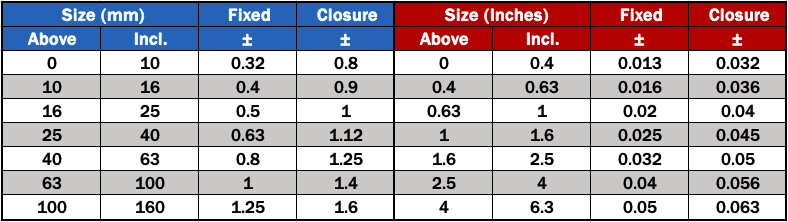

- A4 (Basic) - A4 tolerance will be used with products where the dimensional control is non-critical and secondary to cost

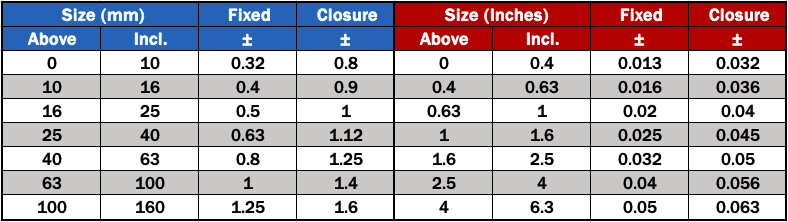

Molded Rubber Tolerance Charts

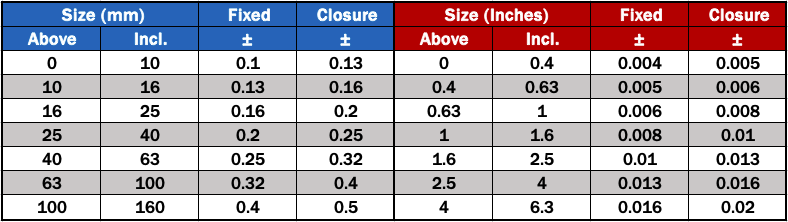

A1 - High Precision

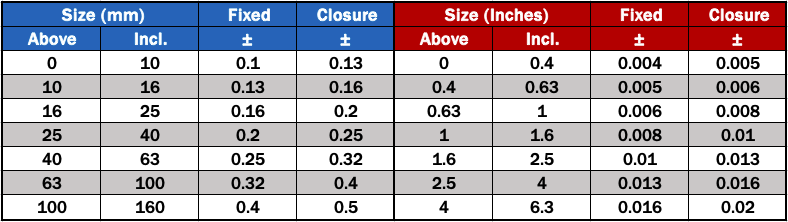

A2 - Precision

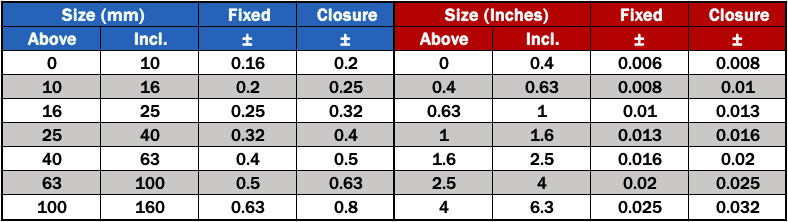

A3 - Commercial

A4 - Basic

Tables above are referenced from RMA (Rubber Manufacturers Association) Rubber Handbook

Factors That Affect Tolerances

A variety of factors can and will affect tolerances in molded rubber products. In this section, we will take you through the most common factors and explain how they impact your finished product.

Mold Design

Rubber molding tools are typically made with two metal plates. Manufacturers can accommodate varying degrees of precision when making the molds, which can result in higher costs based on how precise you'll need them. Variations between the plates and cavities (within multi-cavity tools) can be expected, which is why most high-precision molds will have fewer cavities designed into them.

Shrinkage

Shrinkage is going to occur on all rubber molded components as they cool and has to be factored into the mold's design, based on:

- Material being used - If you cut a tool for a silicone part, but then decide to try using EPDM (or any other elastomer) you'll end up with slightly different dimensions due to the materials having different shrink rates

- Durometer hardness of the rubber material (lower duro/softer rubbers will have a higher shrink rate compared to higher duro/more firm materials)

- Size and design of the product itself

Mold designers need to calculate the amount of shrinkage for the product and incorporate it into the mold's cavity size(s).

Trim & Finish

After a rubber product is molded, the parts will need to go through the trimming and finishing operations that will involve removing the excess rubber (such as flash). Even though this process is typically done to areas that won't affect the critical dimensions, there are some cases where it will. There are different methods that are used to remove excess rubber, such as hand trimming, mechanical trimming, and tumbling. Each method will need to be factored into tolerance requirements.

Environmental Storage Conditions

Even after you receive the final rubber product in hand, there are still environmental conditions that can impact the tolerances.

Temperature plays a role in the fact that it can actually change the dimensions of the material by causing it to shrink or expand. Because of this, you'll need to factor in the temperature at which the product will be used.

Humidity's role comes into play as some rubber materials will absorb moisture resulting in expansion. Because of this, tolerances for moisture expansion and contraction need to be included within the dimensions.

Metal Tolerances vs. Rubber Tolerances

As a company that has been molding rubber for over 50+ years now, tolerance comparisons between metal and rubber is a big point that gets brought up with precision components. Why is that? A lot of companies, especially in the automotive world, want their tolerances for rubber molded products to be exactly like their metal products.

Here's the issue... Metals have different material properties compared to rubber which allows metal fabricators to achieve tighter tolerances. Rubber, on the other hand, is much more sensitive to changes in temperature and humidity and uses different tooling/equipment that impacts the dimensional tolerances.

Quality Part Inspections

Unlike most metals, rubber can be very soft & flexible, resulting in difficulties correctly confirming critical dimensions. For example, if you were to give 5 different people a rubber plug and ask them to measure the top dimension, chances are you'll get more than one result as they may not understand where exactly to place the caliper and when to stop the measurement process.

For example, if you look closely at the image here you'll notice that the caliper is closed tightly, resulting in a distorted part and incorrect measurement.

Devices Used To Measure Dimension

The majority of rubber parts will be inspected using a caliper, but in some cases, especially with high tolerance callouts where consistency and precision accuracy are crucial, you'll want to use more advanced tools, such as optical comparators (examples below).

Keyance

Mitutoyo

Additional Information

What is Compression Molding?

Rubber compression molding is a process where you take a preformed rubber material and place it into a cavity of a heated mold. You then close the mold in order to shape the preformed material using pressure and heat for a specific amount of time in order to cure the rubber. Heat is used to catalyze/harden the material, pressure is used to fill the cavity and remove air voids, and time is required to fully cure/harden the material.

A mold is used to develop the final shape, which contains the male and female components. Once that mold is together, the gap between the male and female (i.e. the cavity) determines the shape of the rubber. The excess rubber will flow out of the cavities into the overflow grooves, providing a trim area.

Rubber Manufacturers Association (RMA)

Rubber Manufacturers Association (RMA), which is now known as the US Tire Manufacturer's Association, is the national trade association for the elastomer products industry. They are responsible for publishing the RMA handbook which was created for the purpose of providing a method for standardizing design requirements for molded rubber products.

Conclusion

When it comes to developing a rubber molded product, it can not be treated the same way you'd go about sourcing a metal product. Rubber has several variables that must be factored in when agreeing about which tier of dimensional tolerances you're wanting. A3 tolerancing will be the most common type of rubber molded product, but if you're in need of A2 or A1, you'll want to work closely with your rubber molder to ensure you have a full understanding of what that will take.

Echo has years of experience working with the most demanding requirements related to compression molding. So, if you have any questions please feel free to contact us any time by filling out the form below!