High Temp Masking Material Alternatives to Silicone

-

By

Lee Lechner

By

Lee Lechner - Jul 6, 2022

High Temp Masking Material Alternatives to Silicone

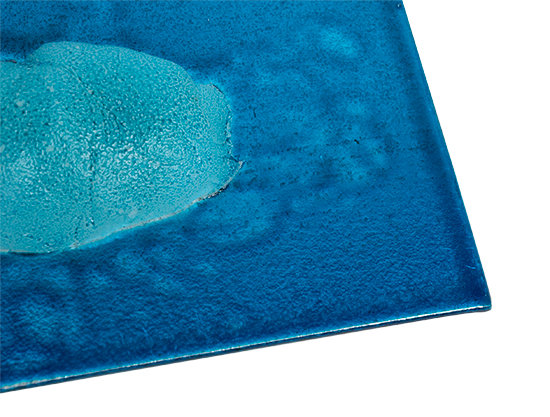

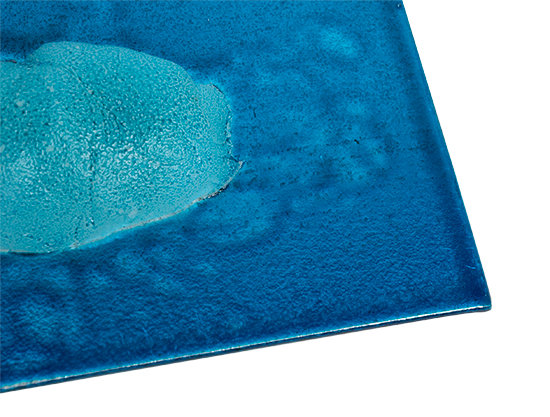

Powder coating and E-Coating typically require masking solutions that can withstand high temperatures. Silicone is the go-to option for most of these cases. Unfortunately, some facilities fear silicone releasing volatiles onto the substrate being coated, resulting in coating imperfections. Many coaters refer to this as silicone residue (refer to the image below). Most coaters don't understand the difference between uncured silicone and peroxide cured & platinum cured silicone. We've covered this more in-depth in a previous post that you can read here.

In the automotive industry, silicone is sometimes not even allowed into the paint production environment due to the fear of silicone volatiles. So, what this means is that they need alternative options. Luckily, we've received these requests many times before, which is why we will take you through what we most commonly recommend and use in place of silicone for high temperature masking applications.

This list of rubber and plastic alternatives has a lot of options, and there is a reason for that. When you work to develop a custom masking, the material and design that are chosen will be primarily based on the following:

- What needs to be masked? Size, shape, and features all play crucial roles here.

- What's your oven temperature? How long will it need to withstand those temps?

- What chemicals will be involved in your process? (Not all materials are chemically resistant)

High-Temperature Rubber Alternatives to Silicone

Ethylene Propylene Diene Monomer (EPDM) - Specialized Formulations

EPDM (Ethylene Propylene Diene Monomer) is a blend of ethylene and propylene polymers. This material offers excellent weather and ozone resistance and good low-temperature flexibility while offering some chemical and heat resistance. Formulated with specific additives to increase temperature rating

Formulated Temperature Resistance: 350F / 177C

Pros: Conforms & seals better than plastics. Compression-molded parts have lower tooling costs. Material price is lower than most alternatives on this list.

Cons: Not as high of temp resistance compared to high-temp silicone

How often it's used the alternative to Silicone: Most common

Perfluoroelastomer (FFKM)

FFKM is a perfluoroelastomeric compound that contains an even higher amount of fluorine than FKM fluoroelastomers, giving it a higher temperature rating. While this material is an excellent option for very high temperatures, it does come down to pricing for most coaters looking into this option.

Temperature Resistance: 626F / 330C

Pros: Excellent temperature resistance. Conforms & seals better than plastics. Compression-molded parts have lower tooling costs.

Cons: Very high price

How often it's used the alternative to Silicone: Highly Uncommon

Ethylene Acrylic Elastomer (AEM)

AEM are synthetic rubbers composed of both ethylene and acrylic monomers.

Temperature Resistance: 347F / 175C (short term)

Pros: Conforms & seals better than plastics. Compression-molded parts have lower tooling costs.

Cons: Price & Not significant temperature resistance

How often it's used the alternative to Silicone: Uncommon

High-Temperature Plastic Alternatives to Silicone

Echo can also injection mold out of high-temperature plastics, but this option means the part will need to be designed and made to exact specs as, unlike rubber, the material cannot simply conform to the area being masked.

Glass-Filled Polyphenylene Sulfide (PPS)

Polyphenylene sulfide (PPS) is a semi-crystalline, high temperature engineering thermoplastic that is chemical and corrosion-resistant. This option will require a high-tooling cost (compared to a rubber compression molding tool) and has to be designed precisely for your application (unlike how tapered silicone plugs can conform to the threads).

Temperature Resistance: 500F / 193C

Pros: Temperature resistance

Cons: Higher material price & tooling investment. It's also more brittle.

How often it's used the alternative to Silicone: Uncommon

Polyetheretherketone (PEEK)

A high-performance specialty plastic that is known for its strength, temperature, abrasion, and chemical resistance.

Temperature Resistance: 350F / 177C

Pros: Higher temperature resistance

Cons: Higher material price & tooling investment. It's also more brittle

How often it's used the alternative to Silicone: Uncommon (More common than PPS)

Polyetherketone (PEK)

PEK is a ketone-based, semi-crystalline, high-performance engineering thermoplastic.

Temperature Resistance: 380F / 193C

Pros: Excellent chemical resistance. Maintains mechanical and physical properties better than PEEK at higher temperatures

Cons: Higher material price & tooling investment

How often it's used the alternative to Silicone: Uncommon (PEEK used in more cases than PEK)

Polytetrafluoroethylene (PTFE)

PTFE is commonly known by its trade name, Teflon®, which you may also know as the material widely used as a nonstick coating for cookware. The main thing to know about PTFE is that it is stable at temperatures up to 500F / (260C).

Temperature Resistance: 500F / 193C

Pros: High-temperature resistance

Cons: Higher material price & tooling investment and is more difficult to injection mold

How often it's used the alternative to Silicone: Uncommon

Conclusion

In the end, we get it. Silicone is just sometimes an absolute no-go for your paint line. When it comes down to when you require custom masking solutions, more than likely, you'll end up going with either EPDM, AEM, PEEK, or glass-filled PPS. There are numerous methods, but your goal will be to find what works for your budget.

If you want to see what we recommend for your process, reach out to us by filling out the form below, and our team of engineers will help design a custom solution based on what material they recommend.