How to Mask Bolts, Studs, and Tube Ends | Metal Coating Guide

-

By

Lee Lechner

By

Lee Lechner - Apr 27, 2023

In this post, we are going to take you through how to easily mask off bolts, studs, and tube ends during coating processes, such as powder coating and electrocoating.

Silicone Masking Caps

The most effective method is to use silicone caps, which can be placed directly over the bolts, studs, and tube ends. Silicone is heat-resistant and can be easily removed after the coating process. They also provide a tight seal around what you’re masking, preventing any coating from seeping through.

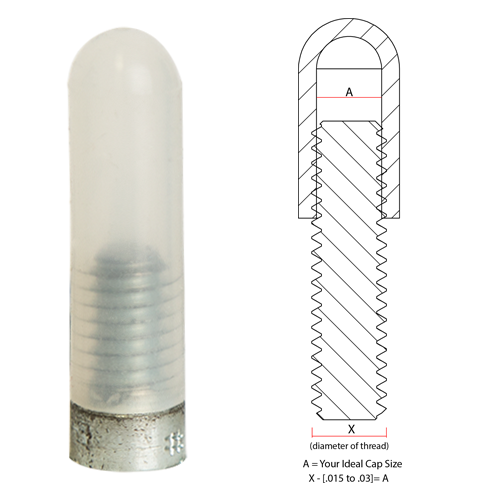

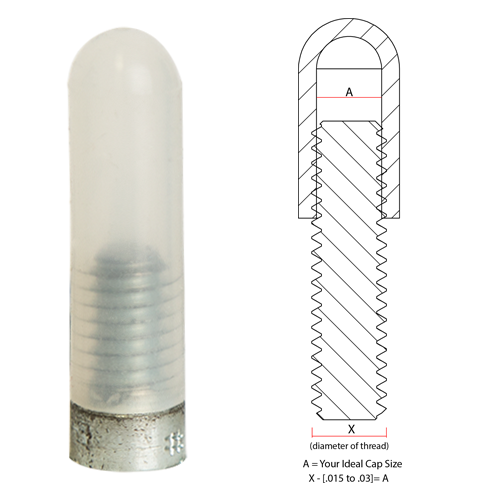

Choosing a Cap

The rule of thumb for choosing the best fit for a silicone cap is to choose one where the ID (inside diameter) of the cap is .015” - .03” less than the OD (outside diameter) of the bolt, stud, or tube you need to mask.

This gives it a snug fit that will seal out paint during your coating process without falling off. If you're masking threaded bolts, here are a couple of resources you can click to download that will give you the outside diameter of the specific thread you're masking:

- Download Standard Thread Chart

- Download Metric Thread Chart

Masking Tapes

Another option is to use high-temperature masking tape, which can withstand the heat of the coating process without leaving any residue. Wrap the tape around the bolt, stud, or tube. The main drawback to this option is that it can lead to inconsistent results based on how it’s applied, and it requires more labor for installation and removal.

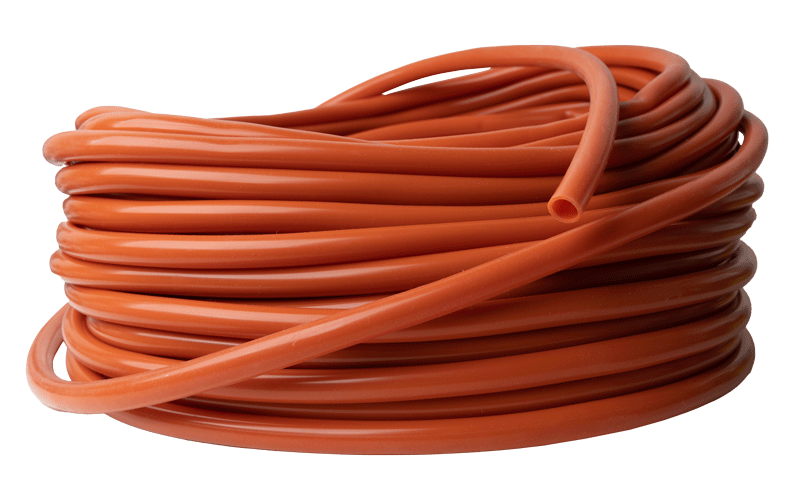

Silicone Tubing

You can also use silicone tubing for longer bolts and studs that the caps can’t cover completely. This option can either be used with the caps or entirely on its own.

Silicone Plugs for Tube Ends

Tube ends are another area that may need to be masked during the metal coating process. One method is to use silicone tapered plugs that fit snugly into the tube end. We recommend finding a silicone tapered plug whose middle diameter closely matches the inside diameter of the tube you need to mask.

Common Problems and How To Handle Them:

- Caps are hard to pull off: This is likely because the cap is undersized by more than .03” or the length of the cap is short. Try out caps that are slightly wider as well as longer (if possible)

- Caps are blowing off: This is likely either because the caps are not undersized enough or they’re coving a tube end where a significant amount of pressure is building up during the curing process. This issue can typically be solved by using a XActo knife to place a tiny slit on the top of the cap or by requesting a custom cap from a masking expert like Echo.

- Paint is building up around the base of the cap: This is a common problem. The solution will be to either try leaving a tiny gap between the cap and the base of the bolt/stud, or you may need to go down the path of a custom masking cap with a skirt around it. The gap and the skirt work to taper the powder in rather than having it build up on the cap.

Conclusion

In summary, masking bolts, studs, and tube ends during the metal coating process is essential to ensure that the final product meets the desired specifications. There is a vast selection of caps and plugs, but only a few will be the ideal option for your application. Because of this, you will want to focus on sizing and efficiency.

If you need assistance or want to try some samples out, reach out to us in the contact form below, and our in-house team of masking experts will gladly help you!