How To Reduce Paint Build-Up During Powder Coating

- By Echo Engineering

- May 22, 2018

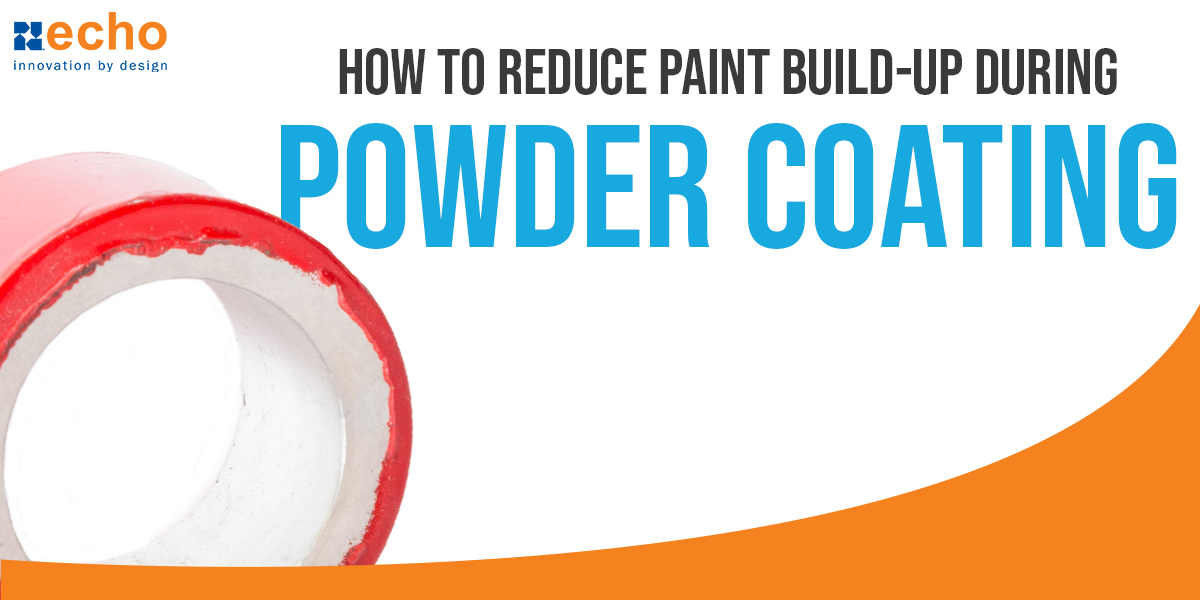

Have you ever experienced paint build up around the grounding area of a masking cap or plug in your powder coating process? Let’s dig deeper to understand why bridging happens and how can we reduce it.

Imagine this. You’ve just completed a powder coating line only to discover the surface isn’t leveled around the masking caps or plugs. Instead, the paint is pushing up against the mask creating a messy finish. Now you’re left with no hope of refinishing without loss of time and money. This unfortunate issue is called bridging and it’s fairly common.

There are solutions to help reduce bridging, but before we look at how to avoid the issue, it is important to understand what bridging means and why it happens.

Paint Build Up Around Masking Caps & Plugs

Bridging is the technical term to describe paint/powder buildup on transitional points of the surface that create roadblocks, like masking caps, plugs, corners, studs, or gaps.

Because of the thick coatings, it is easy for paint to build up. As the paint thickens or if the overspray is occurring, the paint gradually spreads across the surface as far as it can go. When the paint hits roadblocks in the surface, the paint can no longer move forward, and instead, the paint pushes up along the sides of the mask and clumps together.

How To Reduce Bridging

One of the most efficient solutions to help reduce bridging is to implement a custom mask that provides protection around the grounding area of the transitional spot. There are several designs to achieve this protection, but a common solution is to design a mask with a flange wrapped around at an angle like an umbrella or a skirt.

How It Works

When the coater sprays the surface with the thick coating, like powder coating, the umbrella-like flange protects the grounding area from receiving the paint. Then, when the paint begins to thicken, the flow of the thick paint will taper into the untouched grounding area to create a feathered, smooth finish around the mask.

Conclusion

Custom masks are a simple solution to help reduce bridging, and our years of experience in engineering solutions for surface finishers have allowed us to become the experts we are today. If you’re experiencing bridging, contact us and an expert will help provide a sufficient solution for your application and process.