How To Speed Up Your Masking Process

-

By

Lee Lechner

By

Lee Lechner - Nov 18, 2020

Have you ever heard of the old phrase “time is money?” Well, it’s true. The less time it takes you to do a part of your job, the more productive you will be, thus saving money in the process.

So, how can you speed up your masking process? We’ve asked our in-house experts to provide multiple ways to make your masking procedures faster and easier, saving you time and money in the process. Here are the solutions:

Switch to Custom-Molded Masks

If your paint line is going through a high production run of a part, we can't stress enough the benefits of switching to custom-molded masking. Typically, using custom silicone masks can shorten your masking process from minutes to just seconds as most are designed to be placed on the part, and ready to go.

A great example is shown here with a brake caliper. If you've never seen someone try to mask as brake caliper with just green poly tape, it's quite the task. A ton of time and effort has to be put into a part like this. Fortunately, with a custom-molded mask, brake caliper coaters can reduce their masking operations times to a fraction of what it was.

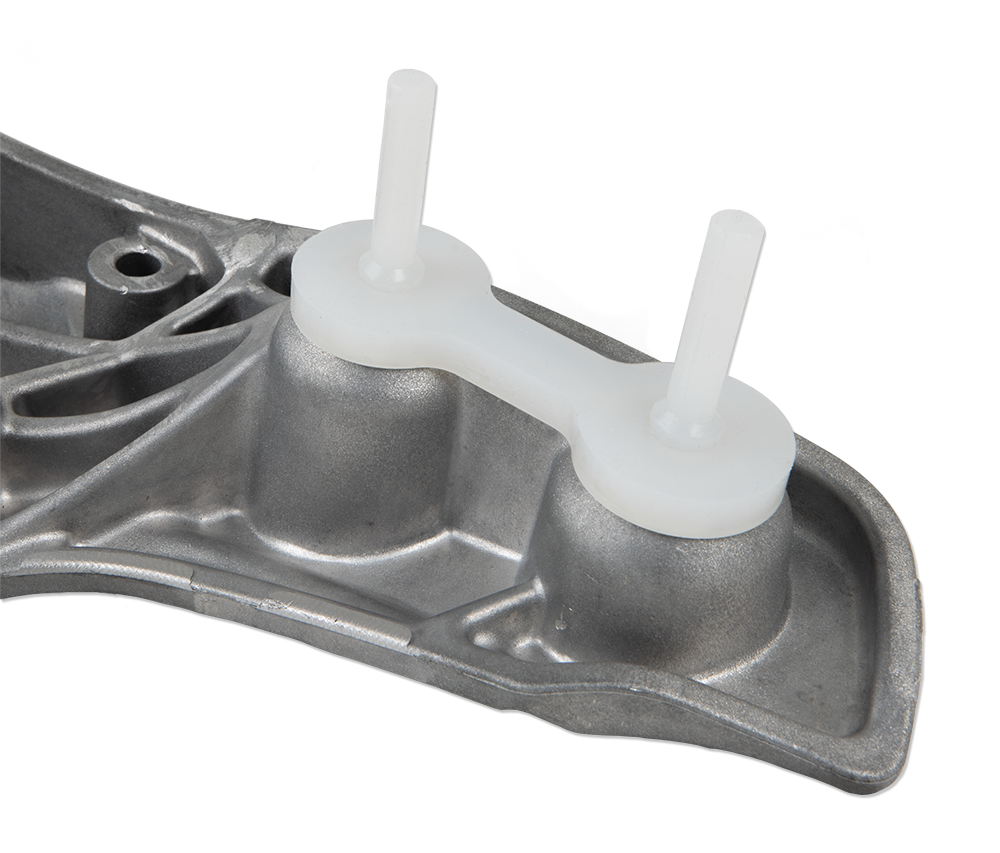

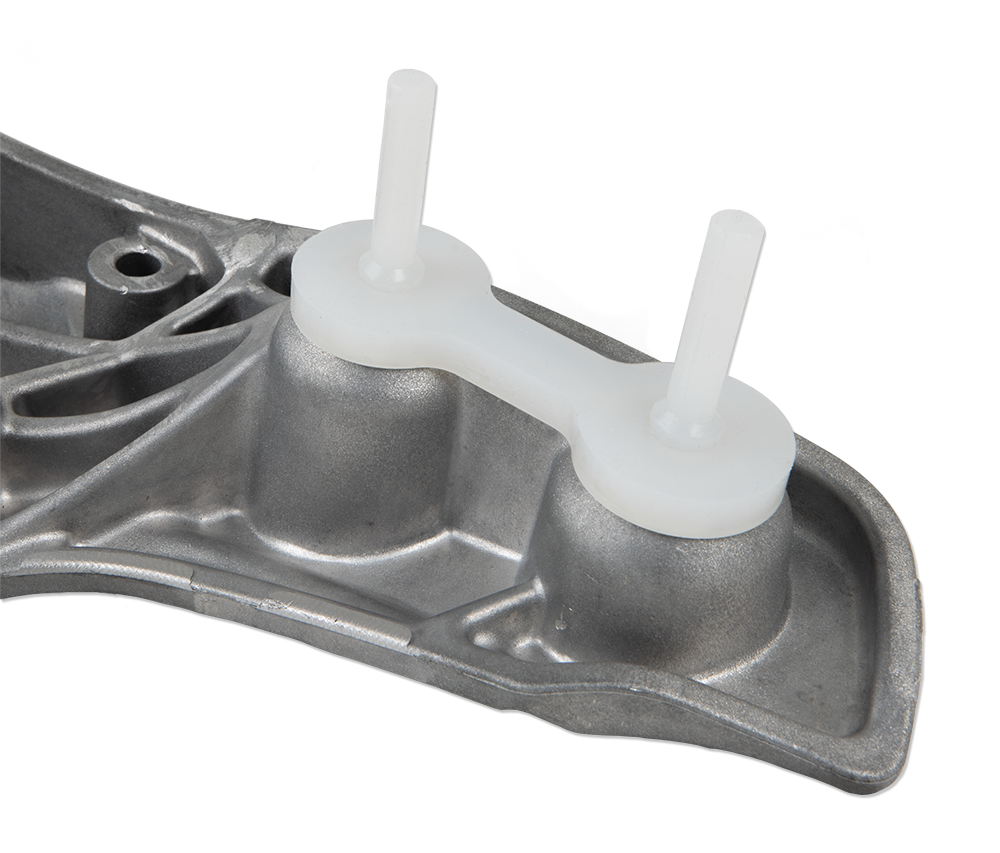

Develop Racking to Integrate Into Masking

Racking/hanging can actually be a hidden gem when it comes to speeding up your masking process. Whether it's developing a mask that the part will hang by or integrating the mask onto your racking system, there are countless ways to be creative with this method.

As shown in the image here, we were able to develop a mask that is actually installed on the metal rack and used to mask the injection-molded back body panel that goes on top of it during the finishing process.

Switch to Die-Cut Masking Tapes

Die cuts are pre-cut pieces of masking tape that are made to the exact size and shape of the surface areas in need of masking. No longer will you need to use a tool like an X-Acto knife to cut tapes to fit.

Die-cuts are produced to your specific needs (size, shape, thickness, material), providing a more precise mask for your finishing process.

Use Die-Cut Kits

Let's say you're masking a batch of brake calipers using die-cuts. There are several sections that must remain uncoated. You're masking line workers will need to ensure they get this done as fast as possible, without missing any portion.

For situations like this, we highly suggest going with a die-cut kit that has all the die-cut pieces on one sheet. This ensures no piece is missed and that your line workers don't miss any section.

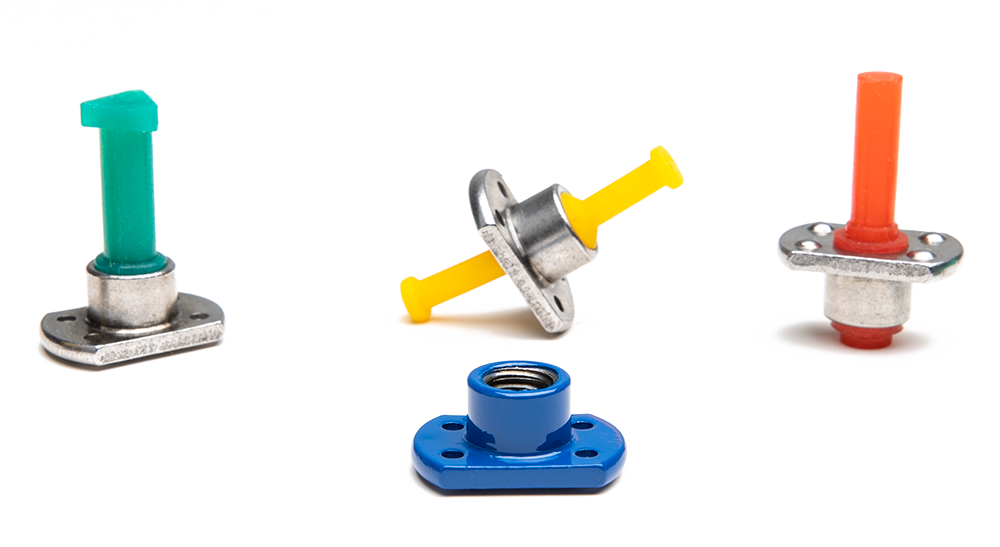

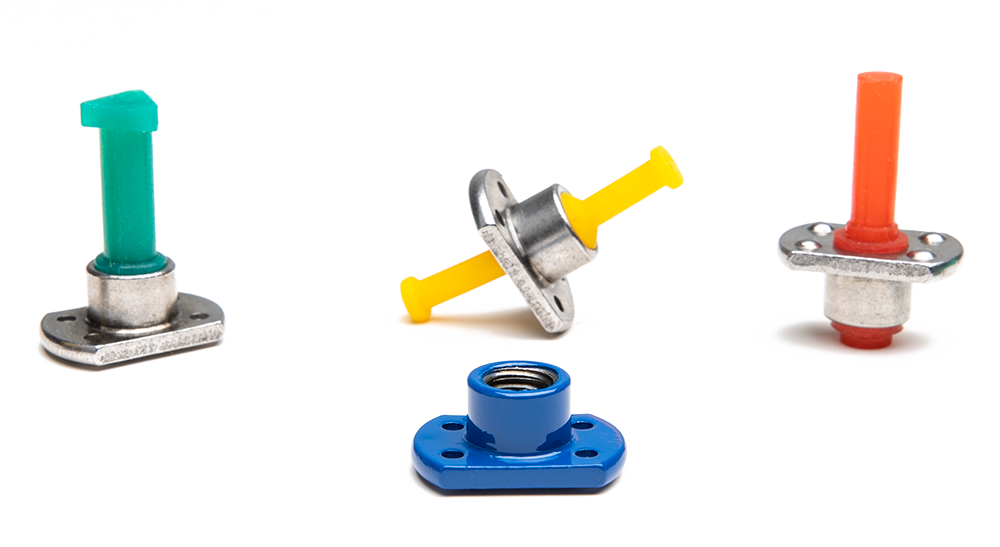

Color-Code Your Masking Caps & Plugs

Masking caps and plugs are available in multiple color variations for sizing identification purposes. Using multiple colors helps speed up the masking process as you’re now able to quickly associate which cap/plug goes to its designated spot rather than wasting time sorting through a variety of different caps or plugs. A few of our customers even use tie-dye plugs to avoid mixing with solid color plugs.

Speeding Up Masking Removal

Remove Tape Shortly After Curing

One of the worst experiences powder coaters can experience is seeing that their tape has baked onto the part they're powder coating. There are two primary reasons to remove the tape shortly after your part has gone through the curing oven:

- The adhesive will be heated, making it much easier to remove. This also means you won't have to worry about the adhesive baking onto the surface, resulting in additional secondary ops

- You'll be able to achieve a much cleaner line, lowering your chances of post-cure fixes

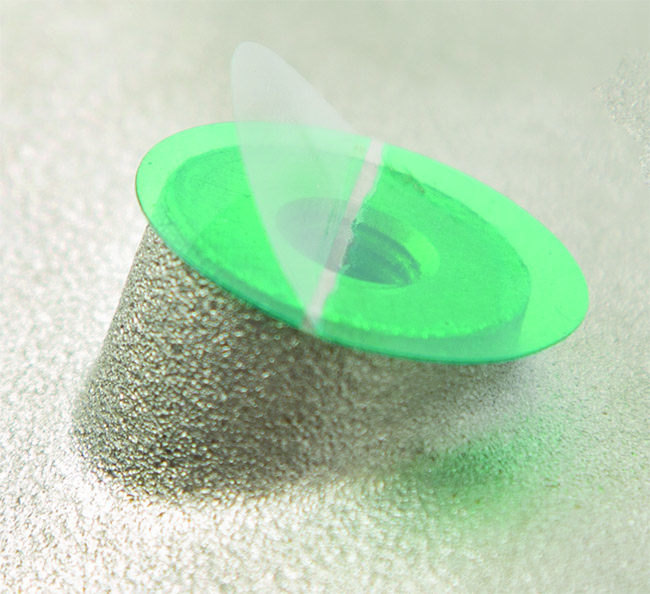

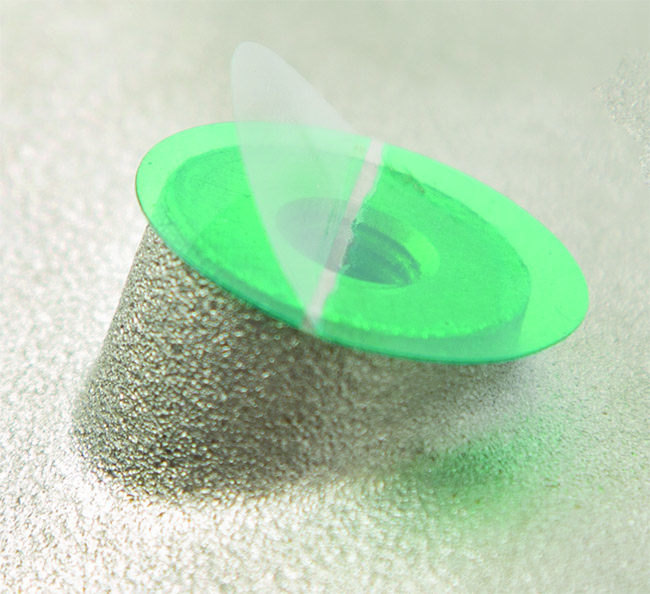

Add Pull Handles for Fast & Easy Removal

This is a must when it comes to most custom molded masking plugs. Adding a pull handle gives your line operators to easily grab & remove the mask without worrying about potentially scratching the surface.

The only main drawback that some powder coaters worry about is that, depeding on the size of the pull handle, there is a chance of shadowing from the handle blocking the powder.

Add Pull Tabs to Masking Tape

Pull tabs are pieces of plastic added to the die-cut backing to provide an easier removal. These tabs make taking die cuts off your finished product much easier and faster while also reducing the risk of causing damage from removing the tape with your fingernails or a sharp blade.

Masking tape removal can be just as time-consuming as the initial application which is why more metal finishers are making the switch to pull tab discs. Pulls tabs can also be added to other masking tape solutions.

Conclusion

Incorporate any or all of these recommended tips to speed up your masking process! Depending on your situation, one may end up being more useful than the other. No matter which you choose, your masking processing speed will be sure to increase, saving you both time and money!

Want to talk to us about which option is best for you? We have experts available to ensure you’re getting the best masking solutions you need.

Visit our Contact Us page and send us a message! We’ll get back with you as soon as possible and collaborate with you to find the perfect solution.