Injection Molding Basics: Hot Runner Systems

-

By

Lee Lechner

By

Lee Lechner - Oct 2, 2020

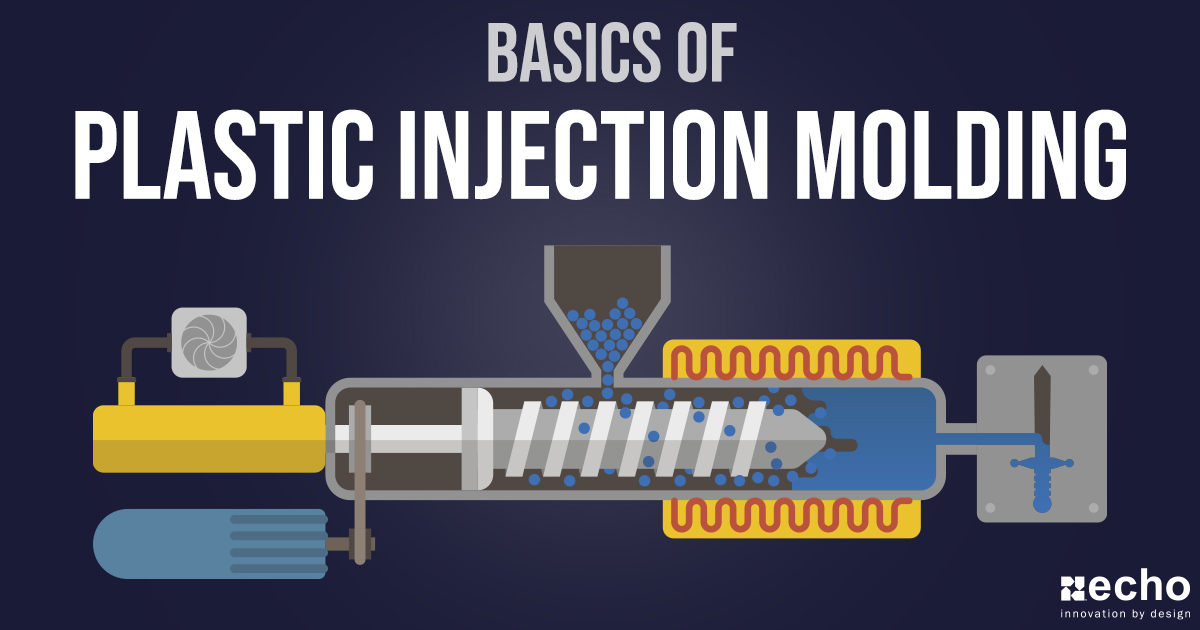

We recently covered the basics of injection molding, but that's just the tip of the iceberg when it comes to the complexity of plastics manufacturing. Today we're going to take you one step further in the comprehensive world of injection molding.

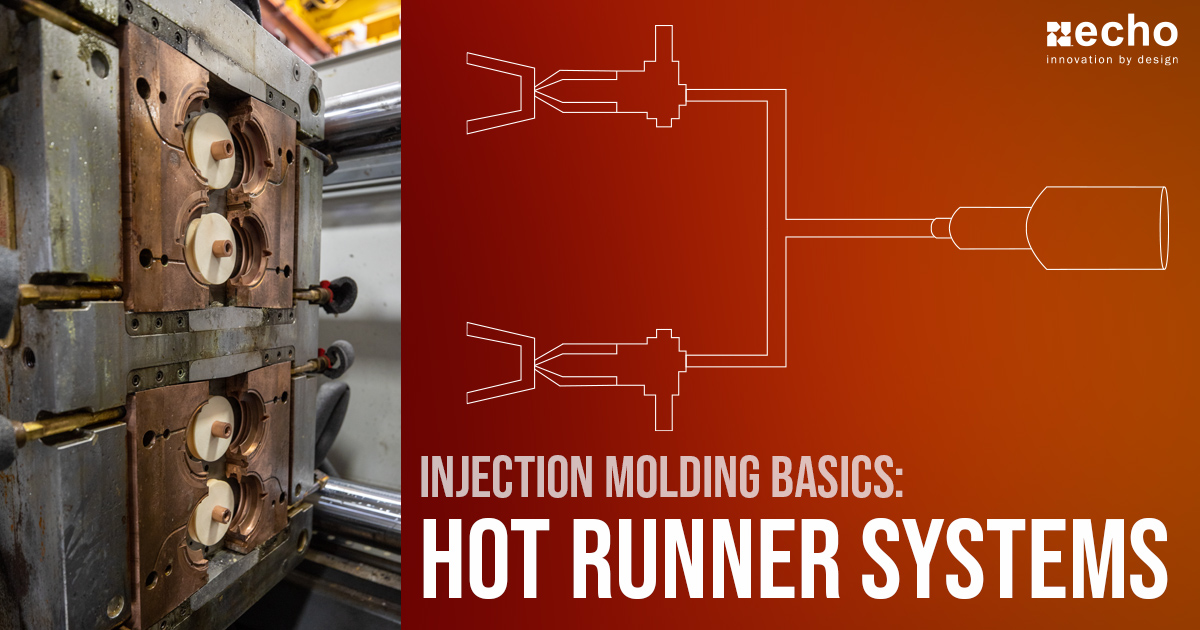

In this post, we'll be covering the basics of hot runner systems, a form of injection molding that has grown in popularity and usage over the years due to its key advantages over traditional cold runner systems. You'll learn what a hot runner system is, the different types, and the advantages & disadvantages of choosing this form of injection molding.

What Is A Hot Runner System?

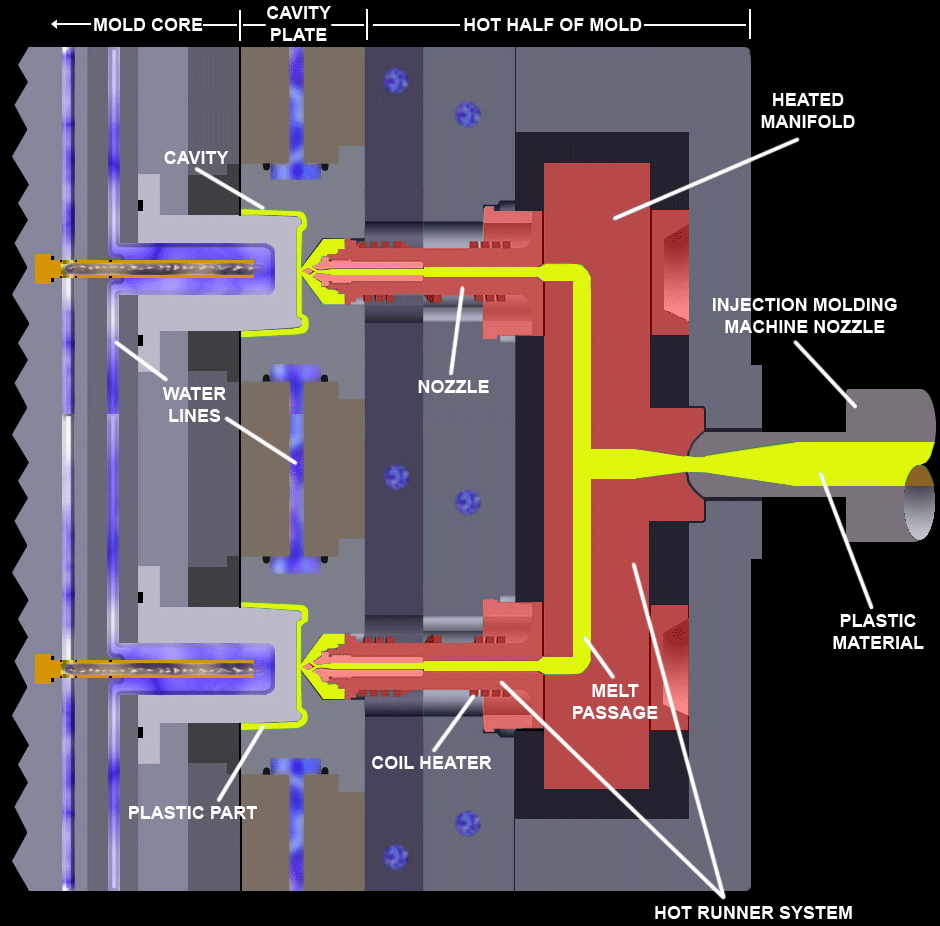

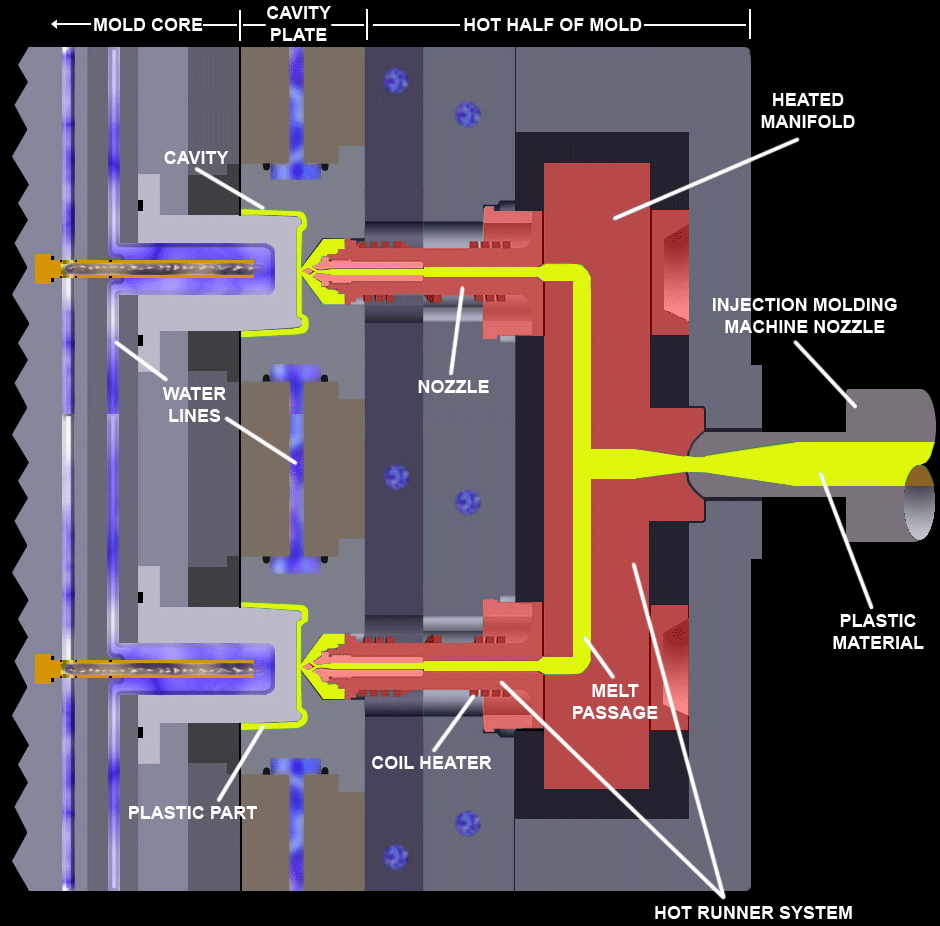

A hot runner mold system is a two-plate injection molding assembly that uses a runnerless heated manifold system and heated nozzles, managed by a temperature control system, to keep the thermoplastic in a molten state until it is finally injected into the cavities through temperature-controlled gates (drops) to form the final part where it is then cooled and ejected from the mold.

Pictured below is what the injection cycle of a hot runner system looks like

Types of Hot Runner Molding Systems

Internally Heated

Internally heated runner systems offer better flow control as they use torpedo cartridge heaters with thermocouples that are mounted inside the runners. Heating the material from the inside out allows heater loads to be much less than externally heated hot runner manifolds, making it very efficient. When more flow control is required, internally heated molds will be the preferred choice.

Externally Heated

Externally heated manifolds use several temperature control systems, such as cartridge heaters, cast-in heaters, heat pipes, heater bands, coil heaters, and torpedo heaters to control the manifold melt temperature surrounding the runner channels and ensure full heat transfer and faster start-up. This type of hot runner system is better suited to polymers that are sensitive to thermal variations.

Insulated Runners

Insulated hot runner molding systems involve oversized passages formed in the mold plate in order to take advantage of the heat insulation properties of the molten thermoplastic. This allows relatively thick layers of thermally insulating thermoplastic to freeze around a large outside diameter of the insulated runner, allow the molten thermoplastic to flow through the center of the insulated runner.

Insulated runners typically have a more simple design and lower cost compared to internally heated and externally heated hot runner systems, but they can cause issues of uneven filling. This system is ideal for heat sensitive thermoplastic polymers and its a good choice for frequent color changes.

Advantages of Hot Runner Molds

Since its introduction in the 1960s, hot runner systems have grown rapidly as more and more advancements have been made with injection molding. There are key advantages to this form of molding as to why its become more widely used. Some of the advantages of hot runner systems include:

- Improved Molding Efficiency: This is due to its ability to provide a uniform melt viscosity and better injection pressure control, reducing the melt shot capacity

- Low Material Wastes: By eliminating the runner, you're eliminating expensive scrap

- Faster Cycle Times: Hot runner cycle times tend to be reduced due to the smaller shot sizes (compared to cold runner systems)

- Improved Part Quality: Hot runner systems are able to maintain a more balanced melt flow, giving you the ability to fully fill and pack cavities. This helps molders meet tighter tolerance dimensional requirements

- Gate Location Design Flexibility: This one is a pretty big deal. Hot runners give molders the ability to place the gate at more ideal locations, optimizing filling and part aesthetics

Disadvantages of Hot Runner Molds

If hot runner systems were perfect, there would be no need to compare them to traditional cold runner systems. Unfortunately, with so much going on in these molds, there are a few drawbacks that must be factored in.

- More Expensive (Mold and Maintenance): Hot runner systems carry a higher price tag due to their more complex mold features and intricate maintenance requirements. They'll also increase your energy consumption due to the constant heating needs.

- Complex Maintenance & Operation Requirements: Mainly stems from the complexity of the additional hot runner components and needs. The internal/external heating tends to also create additional wear and tear on molding machines

- Polymer Thermal Sensitivity: Due to the additional heat exposure, some thermally sensitive materials may not be suitable for hot runner systems

- Color Changes Can't Be Made Easily: In order to change colors, you'll need to a multi-step purge of the current material in the mold. This results in excessive amounts of scrap (especially if you're molding large parts) and hours of machine downtime

Conclusion

Hot runner systems are going to be your ideal, more cost-effective choice for medium to high volume runs where you're looking to produce repeatable results. If you're needing to prototype or test a variety of color options, cold runner systems will be more effective.

Be sure to subscribe so you can be notified of future content when we cover cold runner molding basics and what system will work best for your next project.

Hot Runner Terminology

Hot Runner Controller

A hot runner controller is used to control the temerpature in a hot runner in order to create the most consistant parts possible. Some of the devices used to maintain uniform temeprature control are:

- Cartridge Heaters

- Tubular Heaters

- Cast-in Heaters

- Heat Pipes

- Bands and Coil Heaters

- Torpedo Heaters

About Echo Engineering and Ammex Plastics

Echo Engineering and Ammex Plastics specialize in plastic injection molding, dual molding, and over-molding parts that range from protective shipping caps to some of the most complex injection molded automotive fastening, connecting, and suspension components that can be found throughout a vehicle. Our capabilities range from design, engineering, simulating, prototyping, testing, and manufacturing in order to give our customers the best overall injection molding services.

We take the time to understand what role the component plays in your manufacturing process or product development so that we can confidently recommend a solution that meets your needs - and surpasses your expectations.