Masking Tips to Avoid Costly E-Coat Mistakes

-

By

Lee Lechner

By

Lee Lechner - Mar 13, 2020

Masking Tips for E-Coating

What would happen to your facility if you were to lose your best customer today? What if you lost them because of the issues you’ve been having with masking, but never got around to fix? Leakage and irregular coats caused by improper masking are common issues that only cause you to grind your teeth and start over again. These issues happen when simple steps are overlooked. Stop the rework, and take a look at what you should do to ensure you have a successful e-coating process.

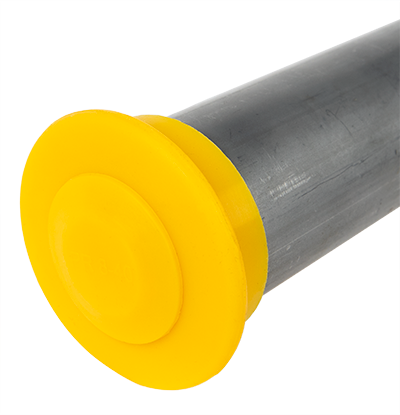

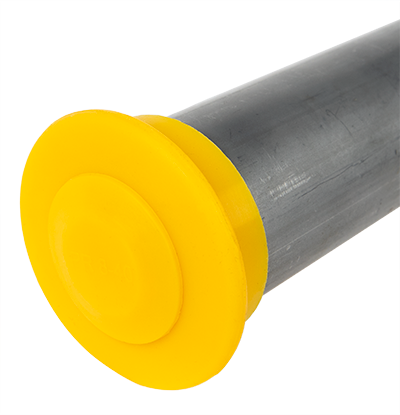

Ensure Your Plugs Have A Tight Fit

Make sure plugs are tightly fitted into the part you are e-coating. If your plugs are too loose, you run the risk of getting paint, pretreat and rinse into areas you want to be kept clean. You also don’t want your plugs popping out in your tanks.

Working Example

If you're needing to mask a through-hole that has an ID of .2675", you'll want to choose a pull plug with an OD that is at least .030" thicker. In this case, we'd pick a pull plug that is minimum .2975". For this hole size, we'd recommend pull plug 01-0020312-04SIL.

Vented Caps & Plugs When Pressure is an Issue

When your components that you're coating are submerged and then baked, and masking caps or plugs are being used, the pressure will likely build. Depending on what you're using, cap/plug blowouts are a potential issue you'll need to worry about.

This is where vented features can come into play. The trick is designing the vents to open up when pressure needs to come out, while also being able to close up when pressure from liquids press down on it. The 3 types of vents most typically used, include:

- Vented Tapered Plug - Catalog option. Sizing needs to be correct though in order to prevent leakage around the sides.

- Pop pin vents (shown in image) - These are great for pressure as the center pin will allow air to escape, but then seals shut to prevent liquids from coming in

Using Masking Tapes & Die-Cuts

When it comes to masking of flat areas on surfaces, high-temperature masking tapes tend to be the go-to option for e-coaters. Surface prep will be absolutely critical before using any tape. A few more tips for achieving best results with masking tapes include:

- Wear gloves in order to avoid oil from your fingers from contaminating the surface and the tape

- Apply pressure with a squeegee or roller to get a secure seal with the metal surface to prevent any leakage

- If leakage is an issue for you, switch to a tape that has more adhesive, like red poly tape

Advanced Engineered Masking for E-Coating

Large scale automotive e-coating lines don't have time for constant rework, which is why they need to ensure their masking parts are going to work when they go to production. In most of these cases, they're in need of a custom-tailored solution that will mask to spec without causing other issues, like blowouts. Below are a few of the advancements that have made it possible

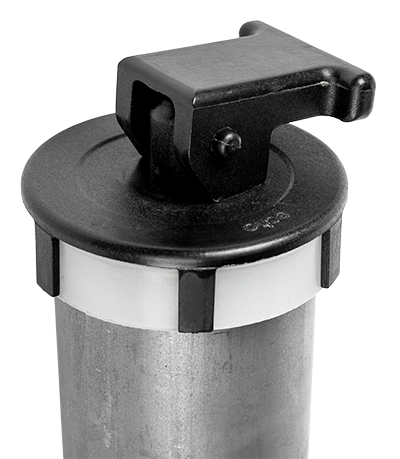

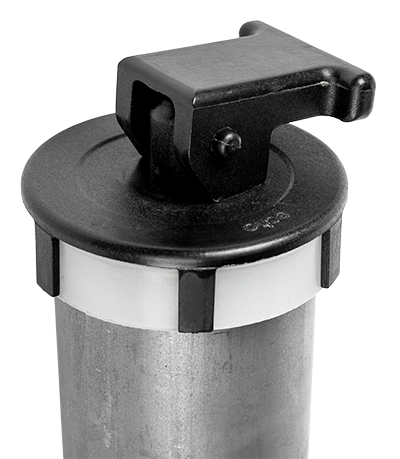

Expandable Caps

These are some of the more highly engineered masks that e-coaters will come across. Expand caps/plugs combine high-temp resistant plastic with silicone rubber in a way that expands when the handle is pulled down in order to seal the metal from having any e-coat leak in, while also preventing it from popping off.

While this does make them a more expensive option, it's more than worth the price due to the cost savings from minimal installation and removal times and a decrease in rejection rate.

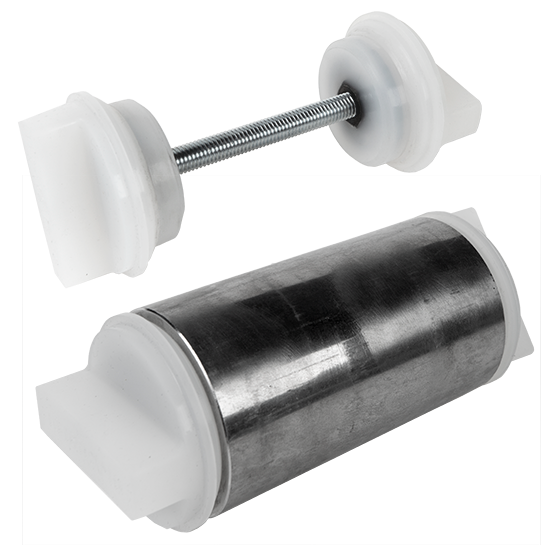

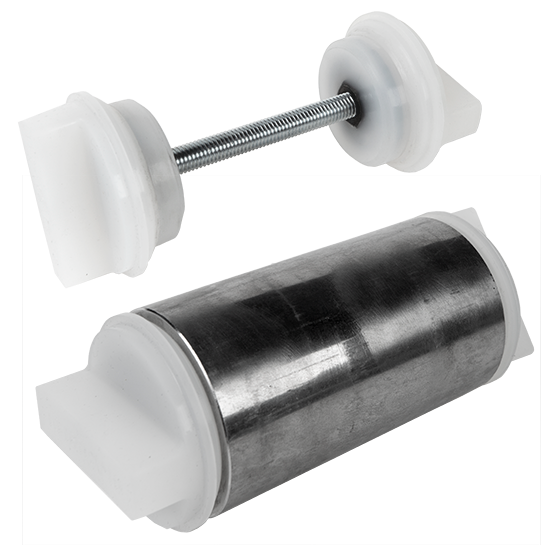

Screw Together Masks

Screw together masks are an excellent option for ensuring a very tight seal without having to worry whatsoever that the plugs will blow out.

These types of masks involve over-molding silicone to a metal threaded nut and bolt. While these are also a more expensive option than catalog options, they are reusable and reject rates will more than likely go significantly down.

Conclusion

If you don’t know how to do something or aren’t entirely sure if your process is as efficient as possible, ask someone. Do not be afraid to reach out for help. Everyone does it, and it will not negatively affect your e-coating process, so you have nothing to lose! The above advice should help give you an easier and safer e-coating process, but please reach out to us if you have any questions, masking issues, or you'd like to discuss with our engineers how to improve your masking operations.