The Importance of NVH with the Rise of Electric Vehicles

- By Echo Engineering

- Jul 25, 2017

The current automotive market is all about refinement – making a consumer’s ride as comfortable as possible. Buyers crave value. Users want quality. And a noisy drive to work doesn’t scream luxury.

If you were to look up reviews on current electric vehicles, you'll find some consumer complaints like this:

"...we were having problems with the car from a strange rattling sound emanating from the vehicle and the sound of wind as we drove"

And...

"...the whole car squeaks, creaks and rattles"

In this post we'll dive into what is NVH, the sources of NVH issues in EVs, and some of the increasingly popular components used to help reduce a vehicle's NVH pain points.

What is NVH?

NVH (Noise, Vibration, and Harshness) is the measurement, study, and modification of the noise and vibration characteristics of vehicles.

The buyer psychology behind the desire for a luxe riding experience increases the need for NVH management, even as the demand for seemingly quieter electric vehicles (EV) grows. Engineers must consistently work on combating the noise (what you can hear), the vibration (what you can feel), and the harshness (the effect bumps and thumps have on the car’s cabin) that threaten a consumer’s experience when riding in an automobile – whether the car be a gasoline vehicle or an electric vehicle.

NVH in Electric Vehicles

Electric vehicles lack the internal combustion engine found in traditional cars. Though this is a positive shift for many reasons, it presents new challenges from different sources of NVH. In traditional vehicles, the engine masks the typically noisy and undesirable behaviors of a car, while the quiet motor in an electric vehicle means every sound or vibration is now more audible.

Sources of NVH in Electric Vehicles

Without an engine vibrating and generating noise that would normally cancel out certain squeaks and rattles, engineers are having to improve upon or create from scratch solutions to prevent or at least reduce NVH. Some of the sources of NVH that need to be addressed include:

- Cooling Fans

- Transmission

- Road Noise

- Brakes

- Fluid Routing Lines

- Wind

- Actuators

- Alternator

- Doors

- Panel Holes

- Mounting Brackets

These are just a few of the many sources. Although challenging, it creates a great opportunity for advancement, as electric vehicles present the prospect of achieving much lower NVH levels than once thought possible.

Solutions Used to Reduce NVH

NVH engineers are challenged with what route to take to improve their vehicle's NVH, whether it's isolating a component or custom engineering a way to absorb the noise or vibration energy. Below is a list of some of the types of solutions that Echo has developed over the years.

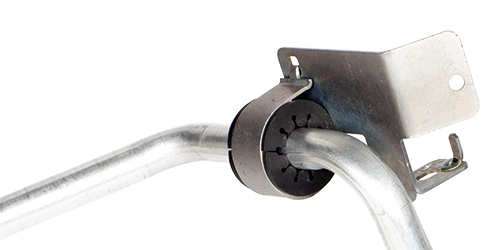

Non-Conductive A/C Line Grommets

Custom rubber tube grommets reduce NVH by preventing metal-to-metal contact and limiting the movement of metal tubing. The custom-designed internal ribs give the fluid routing line assembly the ability to be flexible, while significantly reducing the amount of vibration that occurs. And they’re made with a custom EPDM rubber formulation that is non-conductive (developed by pulling out the carbon black), aiding in the prevention of galvanic corrosion.

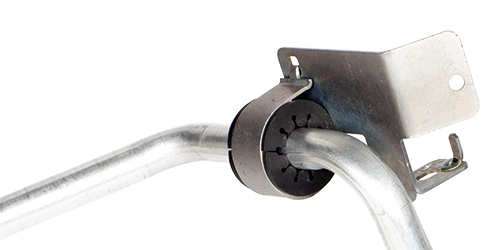

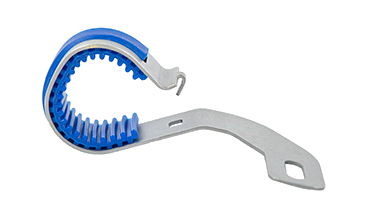

Metal Bracket Rubber Inserts

Similar to the A/C line grommets, rubber inserts are designed specifically to prevent metal-to-metal contact with the bracket and metal tubing, and reduce vibration with it's ribbed design.

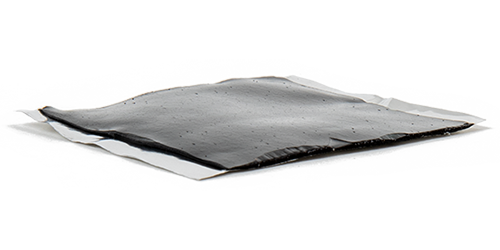

Butyl Patches

Panel holes found throughout a vehicle’s body are typically covered with butyl foil patches (foil backed with butyl adhesive). These work as a great way of sealing out liquids, as well as reducing the amount of noise that enters a vehicle's cabin. In NVH applications, manufacturers typically go with a thicker amount of butyl.

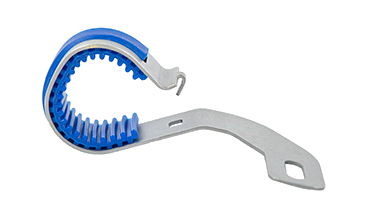

Rubber Panel Plugs

Rubber panel plugs are another great way of covering a vehicle's panel openings. The ideal panel plug is a small component that does three major things – it reduces noise transmission into the cabin, it is watertight, and it installs with ease. Rubber panel plugs accomplish all three tasks, a feat that is not easily duplicated.

The general nature of plugs supplies an improved installation quality, compared to butyl foil patches, as they eliminate the tendency toward human error of not completely covering the hole. EPDM panel plugs are also rubber, rather than plastic, which seals out moisture better than plastic and provides superior noise reduction.

Rubber - An Ideal NVH Material

Usage of rubber in NVH applications continues to grow as the Electric Vehicle market climbs. Due to its versatility, high density, and consistency, rubber is an ideal NVH material. The high density of rubber materials like EPDM gives it the ability to better absorb sound and vibrations compared to plastics, while its consistency allows sound and vibration to be evenly distributed throughout the material.

Conclusion

NVH management is more challenging due to the increased requirements of electric vehicles, but it is, overall, more fruitful – a peaceful, silent drive is now more attainable than ever before. Get in touch and tell us about your next NVH project, and together we’ll create the superior ride that consumer’s desire!