Capablities

Echo designs, manufactures, and supplies rubber, plastic, & adhesive solutions designed for Connecting, Fastening, NVH, and Sealing applications. Our capabilities primarily include:

- Design Engineering - In-house team of engineers that develop new designs and optimize existing ones to ensure products meet your requirements.

- Prototyping & Validation - Innovations in our prototyping and validation process are used to bring new products to life faster than ever.

- Tooling - Our engineers are experienced in choosing and optimizing tooling options for tight-tolerance requirements, both internationally and domestically.

- Manufacturing - We have over 50+ years of manufacturing experience, converting, die-cutting, and molding industrial automotive components throughout the vehicle.

Core Manufacturing Capabilities

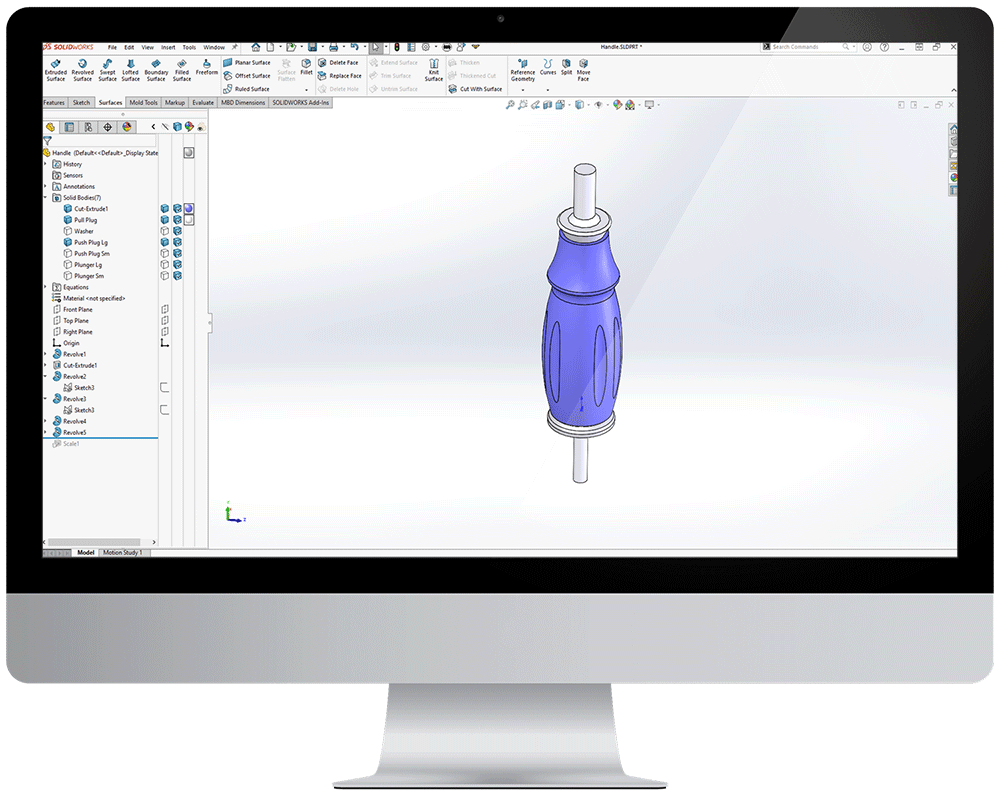

Design Engineering

An area that sets Echo apart from our competitors is our in-house team of design engineers. When it comes to custom projects, our engineering capabilities include the following:

- Ideation & Design

- Design for Manufacturability (DFM)

- Design for Assembly (DFA)

- Finite Element Analysis (FEA)

- Material Expertise

- Rapid Prototyping

Quality Assurance

Testing Capabilities

Documentation / Certification Management

- Tensile

- Tear

- Durometer

- Compression Set

- Rheometer

- Ozone

- Resistivity

- Oil

- Custom Gauges / Fixtures

- 3 Axis Smart Scope

- ISO 9001:2015 (Echo Engineering)

- IATF 16949 2016 (Ammex Plastics)

- PPAP

- REACH / RoHS (1, 2, and 3)

- Certificate of Compliance

- Material Testing Report

- Inspection Report

- MSDS / SDS

- NAFTA Certificate

- 8D / SCAR

- Technical Data Sheets

- Lot Tracking / Traceability

Validation & Fulfillment

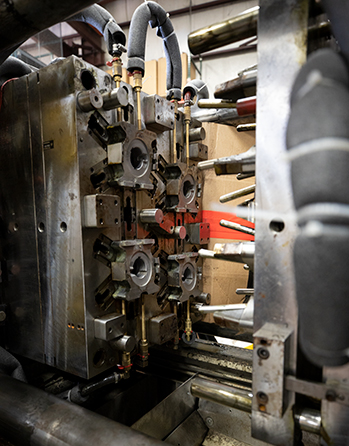

Rubber Molding

Plastic Molding

- Compression Molding (50-600 Tons)

- Over-Molding

- Injection Molding

- Liquid Silicone Molding

- Extrusion (including co-extrusion)

- Transfer Molding

- Rubber-Like Prototyping (3D Printer)

- 1-Week Silicone and EPDM Prototyping

- Injection Molding

- Over-Molding

- Plastic Rapid Prototyping (3D Printer)

- Extrusion (limited)

- Seam Welding

- Assemblies & Sub-Assemblies

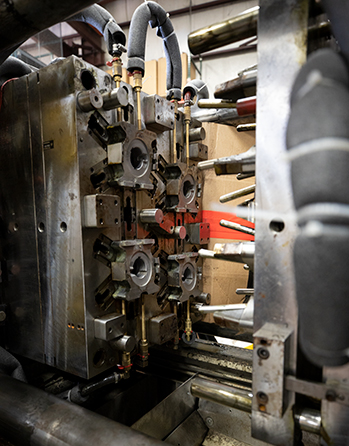

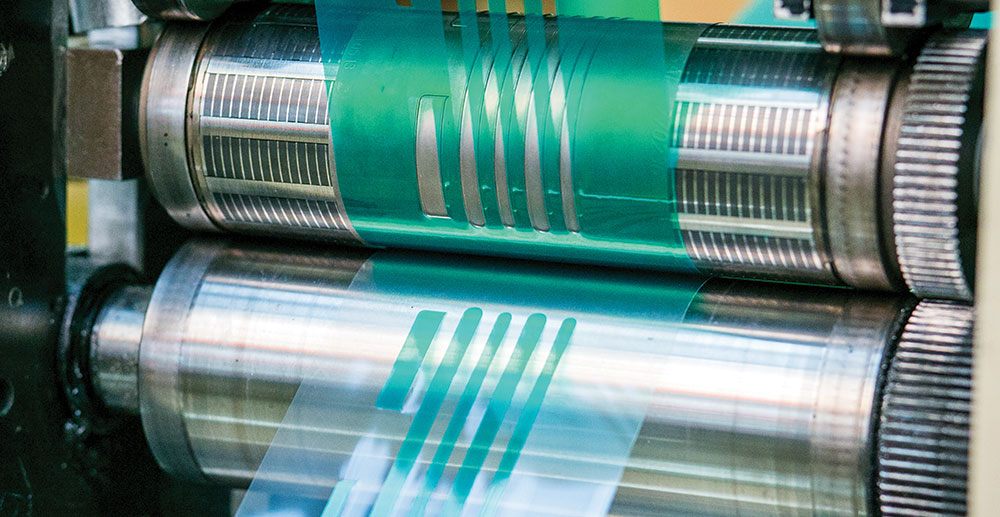

Tape Converting & Die-Cutting

Echo Engineering specializes in converting many different materials with and without adhesives. Common materials, such as catalog tapes and rubber sheets, are stocked in-house.

Capabilities Include:

- Rotary Die-Cutting (10" & 30")

- Overhead Die-Cutting (27"x27")

- Slitting

- Laminating

- Logging

- High-Speed Plotter

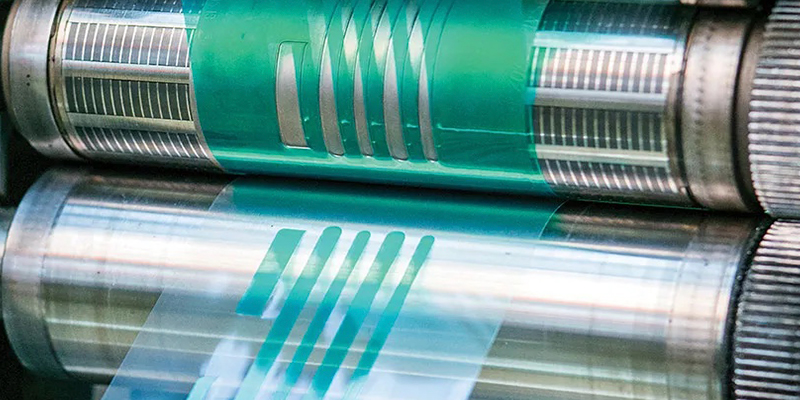

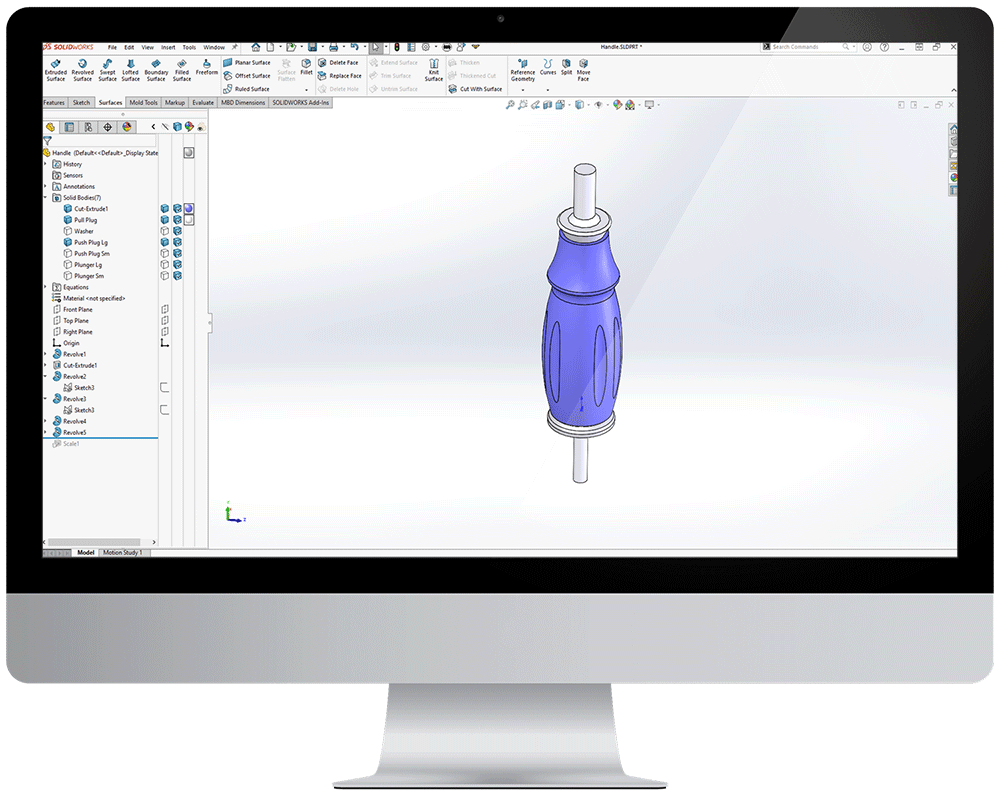

Tooling & Optimization

Echo Engineering and Ammex Plastics understand that before tooling up and sending your project into production, it is vital to review it with you to ensure manufacturability and meet your requirements.

Using the part and mold design, our engineers use SolidWorks and mold flow analysis to determine what modifications need to be made.

Our engineers will work with you every step of the way to review elements that will play a critical role, including:

- Material Selection

- Molding Method (example: Injection Molding vs. Compression Molding)

- Gate Locations & Material Flow

- Ejector Pin Locations

- Durometer

- Ergonomics