Rubber Molding | Custom Product Capabilities

Echo Engineering has over 50 years of experience in designing, prototyping, and full-production manufacturing of a variety of rubber-molded products you'll find throughout a variety of different applications. From automotive grommets, boots, and bushings, to outdoor lighting gaskets, Echo has an extensive background that stems from our core background in design engineering, material formulation, tooling, and our ability to provide our customers with a mix of both low-volume and high-volume production services.

Rubber Manufacturing Capabilities

Manufacturing Processes

- Standard Compression Molding (50-600 tons)

- Injection Molding (300 tons)

- Transfer Molding

- Vacuum Molding (250-400 tons)

- Single Extrusion

- Dual Extrusion

Tooling Capabilities

- Automated CNC

- Vertical Mills

- Horizontal Lathes

- EDM

- Ultrasonic Polishing

- Graining

- Chrome Plating

Secondary Operations

- Over Molding

- Sub Assemblies

- Adhesives

- Lathe Cut

- Splices / Hot and Cold Bonding

- Hole Punches

- Pad Prints

- Assemblies

- Pantone Color Matching

- Screen Printing

- Cryogenic Trimming (rubber flash)

- Post Curing Ovens

- Custom Packaging

Rubber Materials

- Natural Rubber (NR)

- Styrene – Butadiene (SBR)

- Ethylene Propylene (EPDM)

- Chloroprene, Neoprene (CR)

- Nitrile (NBR)

- Silicone (Si, Q, VMQ)

- Polyacrylic (ACM)

- Epichlorohydrin (ECO)

- Ethylene Acrylic (AEM, Vamac)

- Hydrogenated Nitrile (HNBR)

- Fluorosilicone (FVMQ)

- Fluorocarbon (FKM) / Viton®

- Many others, ask an Echo Representative

Our Process

Step 1: Design

Our engineering team will work with you through our Design for Manufacturing (DFM) process to either optimize your current design or design a part from scratch to meet your specific requirements. Our process includes reviewing the materials needed, the functionality of the design, the moldability of the part itself, and any tooling optimization.

Step 2: Prototyping & Validation

Once the design is approved, we can move on to prototyping the part to validate that it works for your application. The two methods we use to do this are:

- 1-Week Silicone/EPDM Rapid Prototyping: We developed a proprietary method of creating silicone and EPDM prototypes to give you the ability to test apart's fit, form, and functionality - Learn More Here.

- Standard Prototype Tooling: To get the truest to-production prototypes, you can go the standard route where we will machine a metal mold (typically will be aluminum due to the speed to produce tool) mold to produce your parts.

Step 3: Quality Assurance & Validation

Once prototypes are completed, we inspect and test them (when needed) to ensure they meet your requirements before shipping them to you to test out. If anything is off, we will make revisions and repeat.

Step 4: Tooling Kickoff

Once everything is approved, and a PO is submitted, we will begin production tooling design and kickoff. Part complexity and quantity factor into the timing required to complete the mold. Production tools are typically made using hardened tool steel instead of aluminum. This allows our die life to be extended, reduced maintenance on the dies and a more efficient manufacturing process overall.

Step 5: Production

Once the first shots from the tool are reviewed and approved, the first articles are provided to the customer for their final approval. Pending any final modifications needed, we are able to start fulfilling production quantity orders to ship to the customer.

Let's Get Started

Applications

Sealing

Over the years, Echo has manufactured a wide range of quality rubber molded gaskets and seals. We specialize in seals and gaskets utilized in automotive applications, outdoor lighting, pumps, and electrical systems, to name a few.

Our engineers are well-versed in developing solutions that need to withstand harsh conditions, such as extreme temperatures, chemicals, lighting exposure, and much more.

Parts We Specialize In:

- Gaskets

- Caps

- Sealing Plugs / Panel Plugs

- Door Seals

- Housing Seals

- Boots & Bellows

- Custom Masking Solutions

- Parts with adhesive backing

NVH Applications

Rubber-molded products are an excellent way of reducing NVH. At Echo, we have a long history of molding grommets, spacers, plugs, and much more. When working with us, our engineers will focus on part design, material selection, and moldability to ensure parts are being produced efficiently and to your specific tolerance requirements.

Parts We Specialize In:

- Grommets

- Bushings

- Panel Plugs

- Spacers

- Shims

- Bumpers

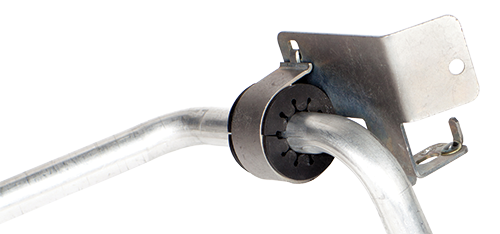

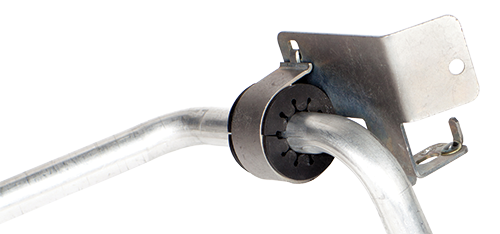

Connecting

Rubber-molded connecting components are typically used to transfer/route fluids or gases from one location to another. Echo is experienced in manufacturing parts used in automotive, lawn & garden, marine, and recreational vehicle applications.

Parts We Specialize In:

- Molded Hoses & Tubes

- Air Intake Hose

- Air Intake Ducts

- Breather Tubes