Core Tech Expertise

50+ Years of Engineering and Manufacturing Expertise

Echo Engineering & Production Supplies, Inc. was founded over 50 years ago in Silicone Valley. Since then, we've developed and focused of 5 Core Technologies that differentiate us from the rest. We chose to become experts in these fields due to increase in demand and need for in-depth engineering & manufacturing expertise.

Masking Expertise

Echo began by making die-cut masking tapes in a garage in Silicon Valley for printed circuit boards. This was the foundation for not only our world-class masking expertise but also played a crucial role in our other Core Technology focuses.

Masking is the backbone of our organization. From high-temperature masking tapes & die-cuts, to catalog and custom compression molded masking solutions. Our team of in-house design engineers is one of the best in the industry at finding the perfect masking solution for your finishing line's needs

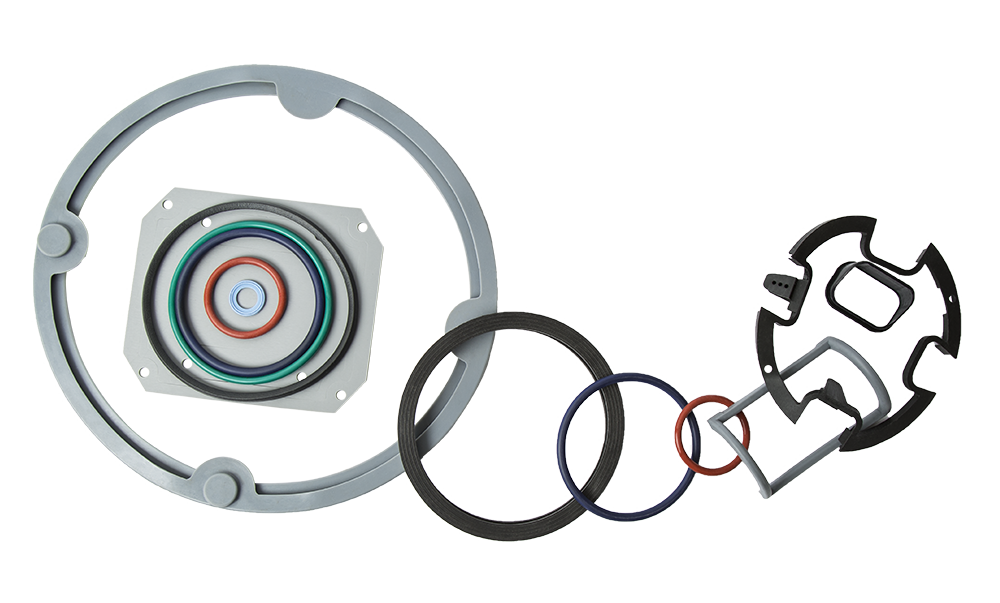

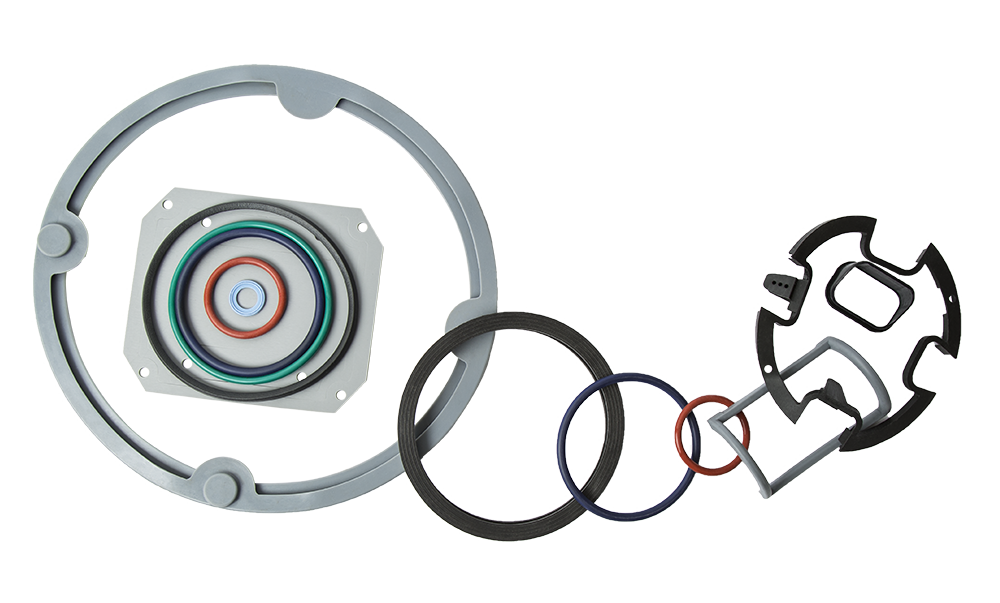

Sealing Expertise

Echo's experience with overhead die-cutting and compression molding set up the groundwork with our expertise in custom OEM gaskets and seals. We initially started in the outdoor lighting industry by manufacturing lense gaskets. The more we did, the more we learned.

After 20+ years of engineering and manufacturing custom gaskets and seals, Echo's products can now be found in today's most popular vehicles, lawn & garden engines, and fluid power components around the world. Our engineers will assist you with a variety of elements that need to be factored into producing an effective seal, from: Design, manufacturability, material, durometer, etc.

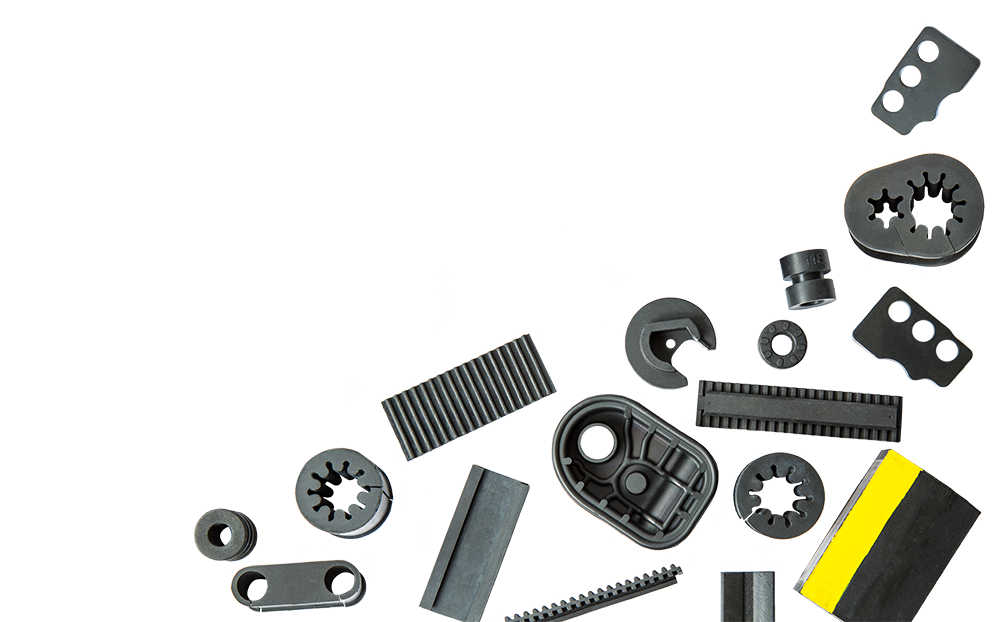

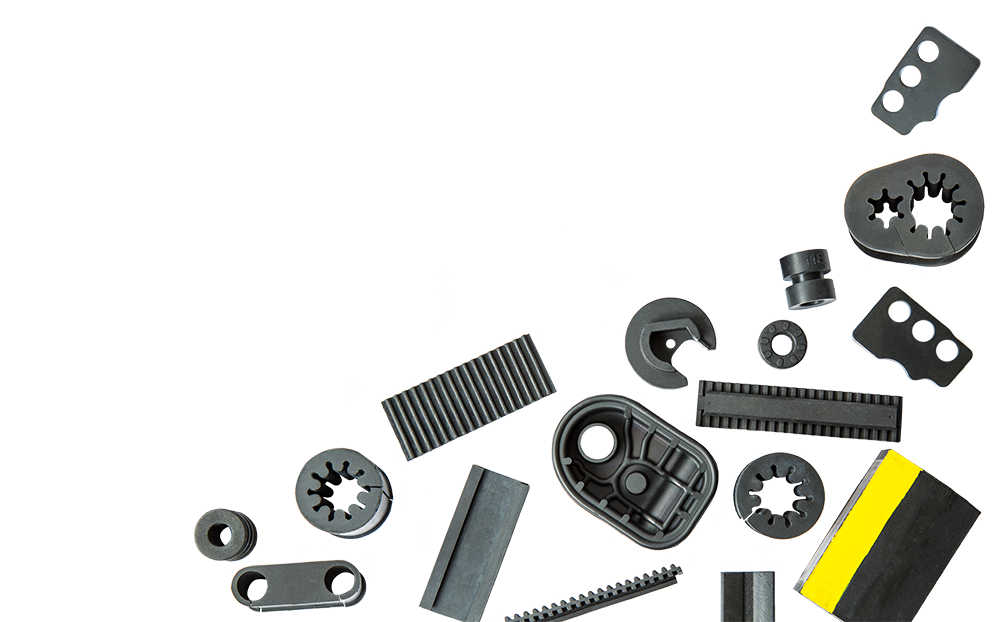

NVH Expertise

As Echo's automotive customer base grew, so did our capabilities. Our experience with compression molding and EPDM led us into engineering and manufacturing NVH components, such as: A/C line grommets, bracket inserts, panel plugs, spacers, and variety of other components.

Echo Engineering now specializes in helping you improve the customer experience by producing components that will reduce any combination of Noise, Vibration, and Harshness. Our design engineers will review your project in order to ensure you're able to accomplish your end-goal and ensure the prodcuts meet their specific testing needs.

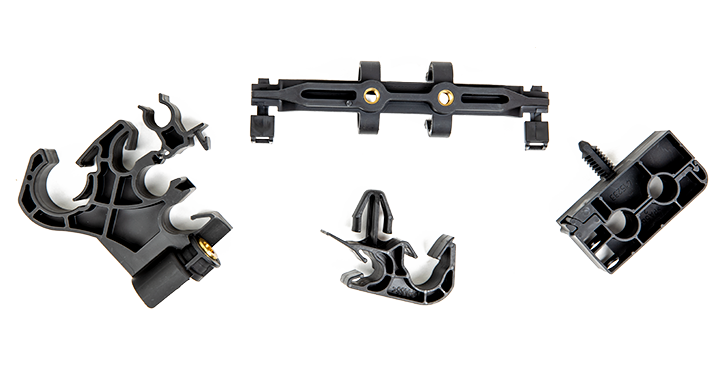

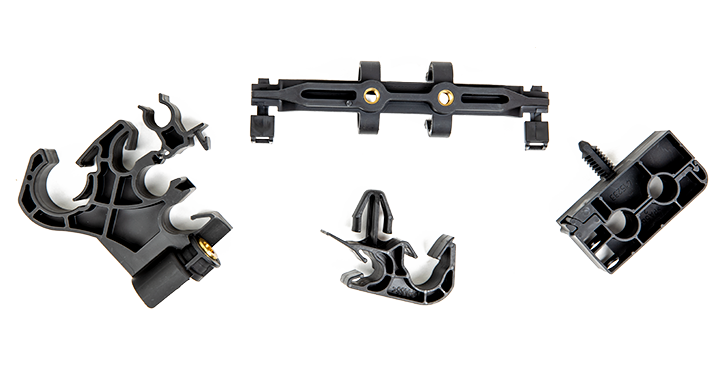

Fastening Expertise

Echo's experience with plastic injection molding and automotive fluid routing customers looking to consolidate suppliers paved the path towards our in-depth expertise of injection molded fastening components. Echo has invested in not only in new testing equipment, FEA software, & engineering training and development, but it also lead to our acquisition of Ammex Plastics (Monroe, MI) in 2017.

With Echo and Ammex, you’ll be working with a team experienced in bringing new clips to life based on performance requirements set by the tier-1 or OEM manufacturer. This is why we’ve brought a lot of testing in-house at our headquarters in Indianapolis in order to speed up our process and develop a more comprehensive understanding of automotive fastening technologies.

Connecting Expertise

With the acquisition of Ammex Plastics came in-depth engineering tool design expertise and injection molding experience of manufacturing complex barbed hose connectors. Ammex Plastics has been tooling up and supplying hose connectors for 20 years, has shipped millions of parts, and runs a PPM rate of <2.

Injection molded hose connectors are not the only components we specialize in though. Echo has manufactured a variety of different compression molded rubber air intake hoses and intake ducts primarily used in the powersport industry. Echo specializes in compression molding, which offers our customers the ability of achieving complex shapes and curves that can not be achieved via vulcanization.