Automotive Fastening Expertise

We are experienced in designing and manufacturing a variety of different automotive clips used on HVAC lines, brake lines, wiring harnesses, EV batteries, and many other applications.

We have invested heavily in the automotive fastening market by developing a library of different designs, hiring plastics and process engineers, adding additional presses, and purchasing new testing and measuring devices. With Echo and Ammex, you’ll be working with a team experienced in bringing new clips to life based on performance requirements set by the tier-1 or OEM manufacturer.

Design, Software, and Testing Capabilities

Echo utilizes customer system requirements to begin ideation then design, develop, simulate, test, and manufacture fasteners that meet or exceed difficult OE criteria for:

- Insertion & extraction forces

- Clamping and opening forces

- Over-molded rubber onto plastic for enhanced NVH performance

- FEA

- FMEA

- Detailed test plans and test reporting

Echo's testing lab capabilities continue to grow fast, from full automotive body panel clip testing to peel testing for tapes and butyl patches. Our custom fixturing capabilities set us apart from the others. We understand that things can change quickly. That is why we utilize in-house custom fixturing to reduce costs and allow for rapid modifications.

Examples of Fastening Features

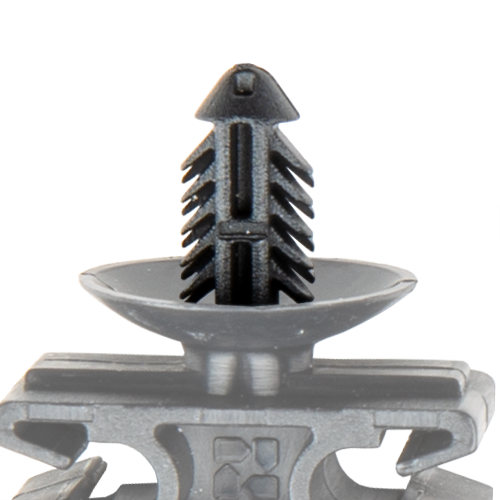

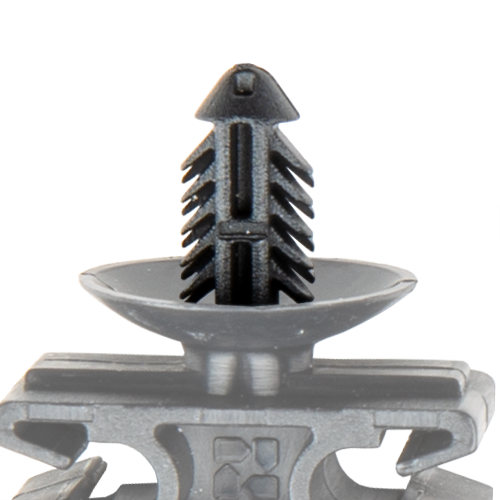

X-Mas Tree Fastener

Wedge Clip

Wedge Clip with TPE Grip

Engineering & Manufacturing an Automotive Fastener

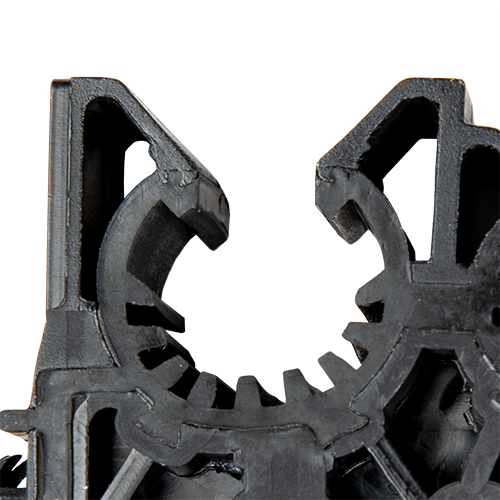

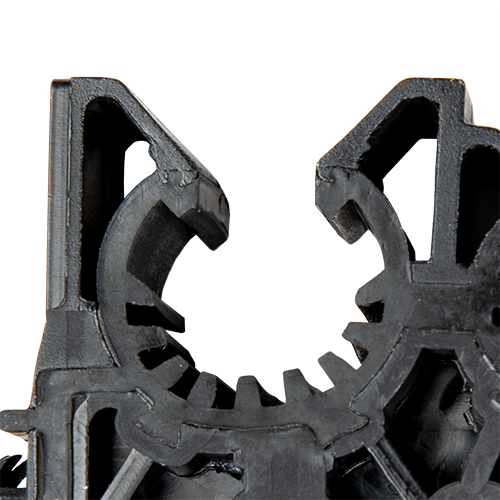

Our engineers have worked extensively over the years on developing a library of fastening designs that have been successfully implemented in a variety of automotive applications over the years. This library knowledge continues to play a vital role in designing new clips and fasteners from scratch based on application requirements.

Living hinges are an excellent design feature for closure needs in many of the clips we've developed over the years. Injection-molded living hinges are thin, flexible joints that join two bodies together that are made from the same material as the bodies.

The challenge with this feature is developing a design that is thin enough to effectively bend without snapping yet thick enough to withstand the stresses exerted on the living hinge during molding and the flexing movement. Our engineers understand critical elements to factor in towards the part's moldability to ensure strong designs that meet your expectations.

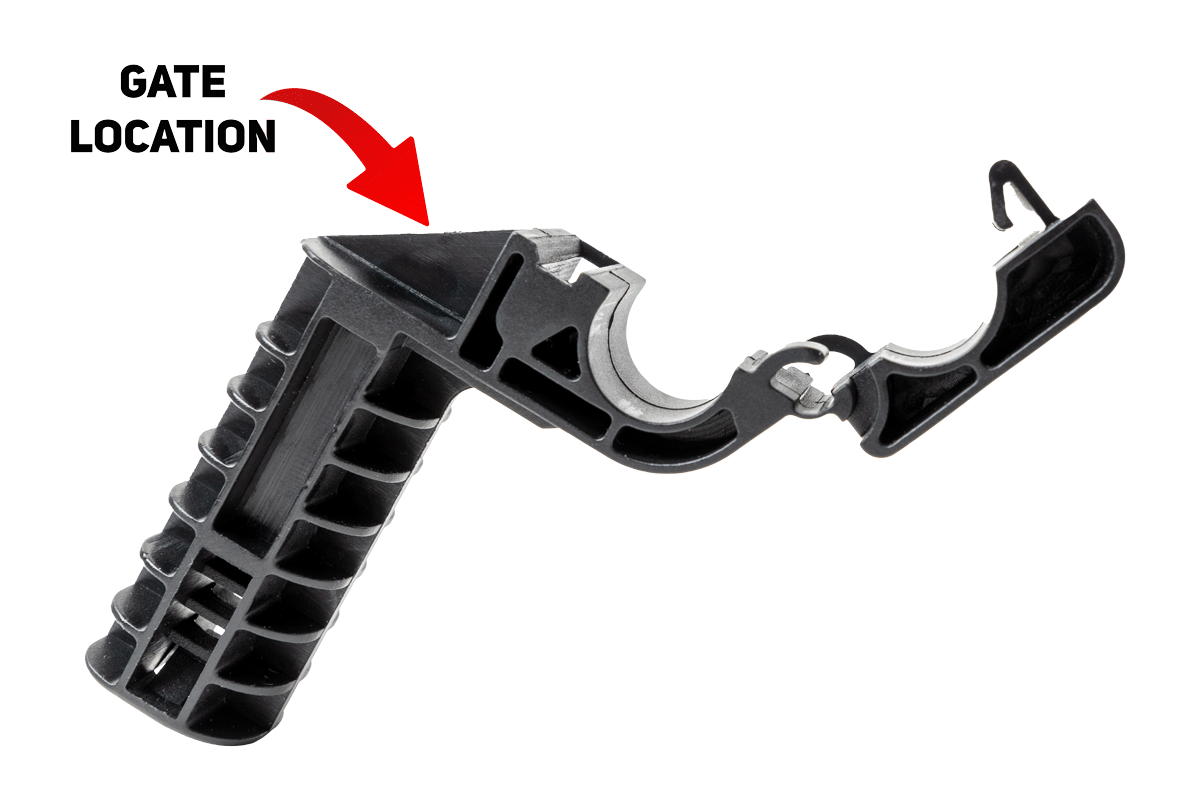

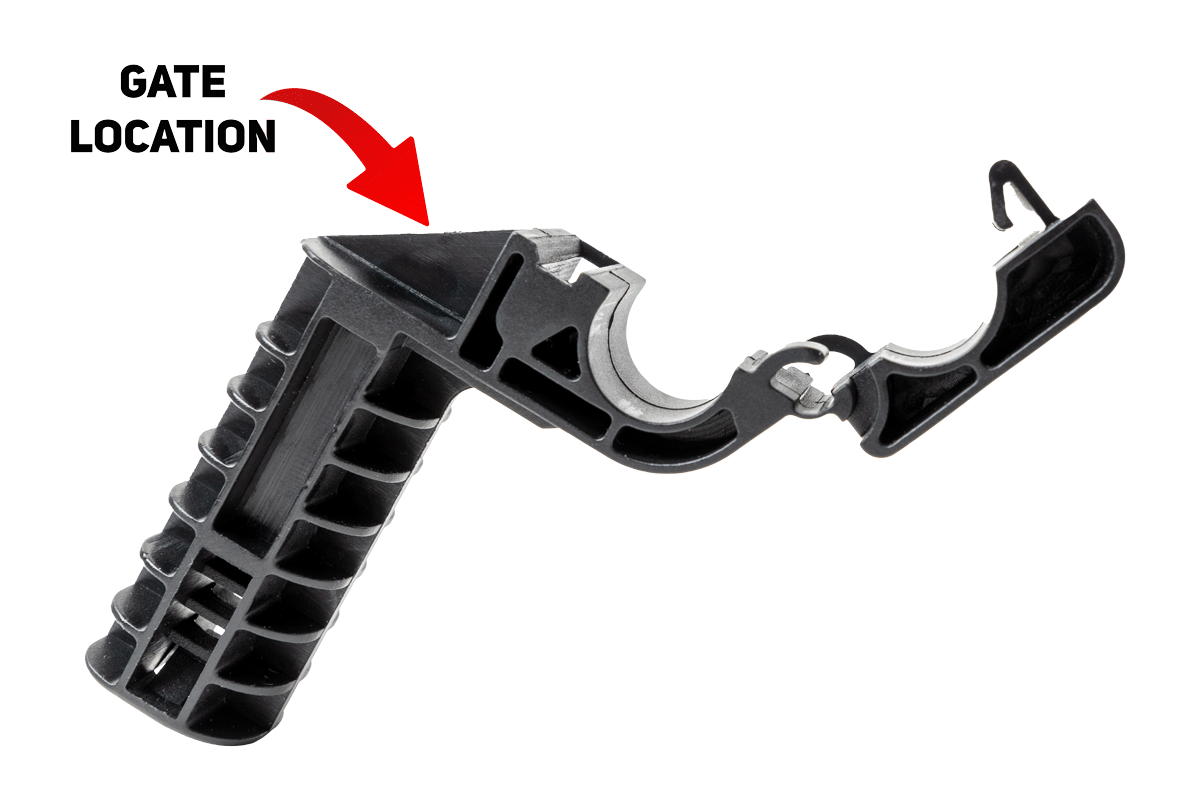

Many of the fasteners and clips used in automotive applications have a wide variety of thick and thin sections that make it difficult to effectively mold. In order to achieve a high performance part that meets strict requirements, our team places a high emphasis on the gate location and design to ensure the part is appropriately packed during the mold process.

Knowledge Center

You May Also Like...

Design Engineering: Plastic Clips & Fasteners

Learn about the different types of clips and fasteners used in the automotive industry, and design elements that make them work.

Benefits of Converting Metal Brackets to Plastic Clips

Using plastic clips has multiple benefits. In the following, we discuss the top advantages of replacing metal brackets with plastic clips.

Automotive NVH (Noise Vibration Harshness

In automotive design, NVH is managed by minimizing the transfer of undesirable noises and vibration into the passenger area.