Heavy Machinery Industry Applications

Masking Expertise

Echo Engineering specializes in masking solutions used by the world's largest heavy machinery OEMs, Tier 1 manufacturers, and metal coating facilities. Echo has over 50 years of experience in masking during their most common metal finishing processes, including Blasting, Powder Coating, Wet Paint, and E-Coating.

Our design engineers specialize in custom masking solutions used on heavy machinery frames, arms, attachments, engine components, wheels, brake calipers, and a variety of other components that need some form of masking. Below are a few examples that highlight what we do.

Problems We Solve

We engineer and manufacture solutions for the biggest names within the heavy machinery / agricultural industries. This means we've seen the countless problems that you've likely run into! If you are dealing with any of these issues below, it's time to reach out to Echo and let our team of engineers solve your headache!

- Shot Blasting Issues: You need a way of masking off areas that are being blasted. This is a common issue in this industry. If your application requires a custom solution, we will likely go with a molded natural rubber part (due to the material's mechanical property's ability to withstand blasting better). Or, if you plan to keep the part on during the coating process as well, we will either go with EPDM or Silicone due to its temperature resistance.

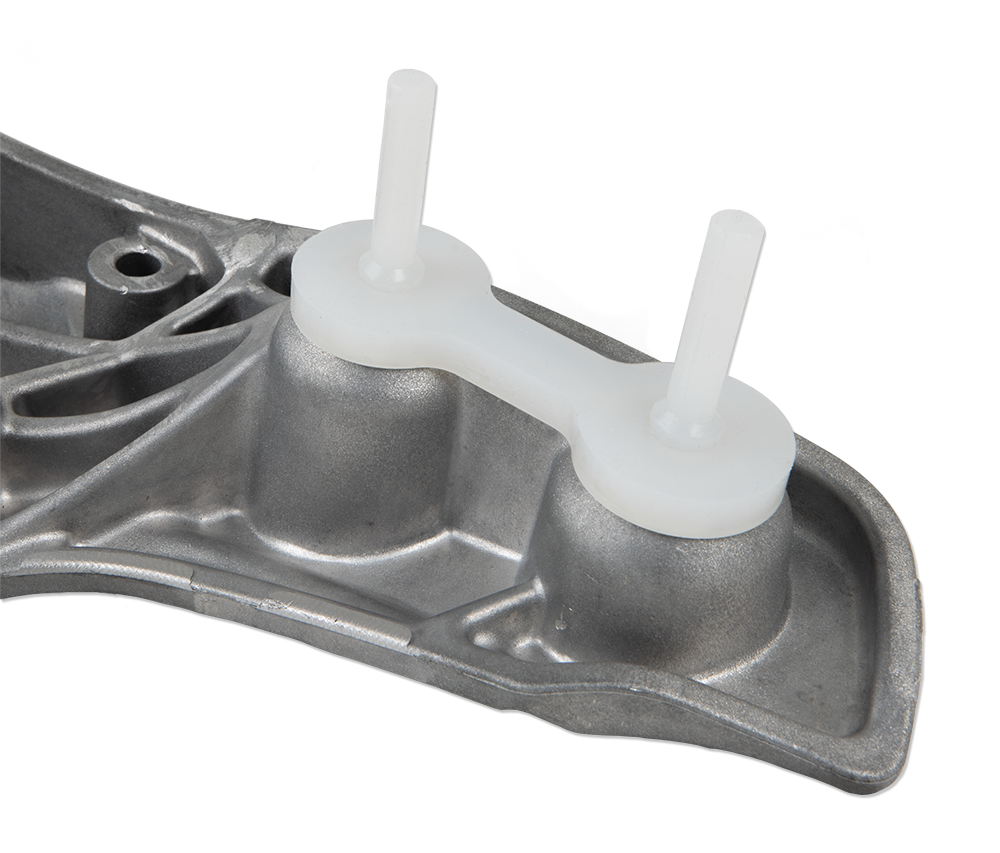

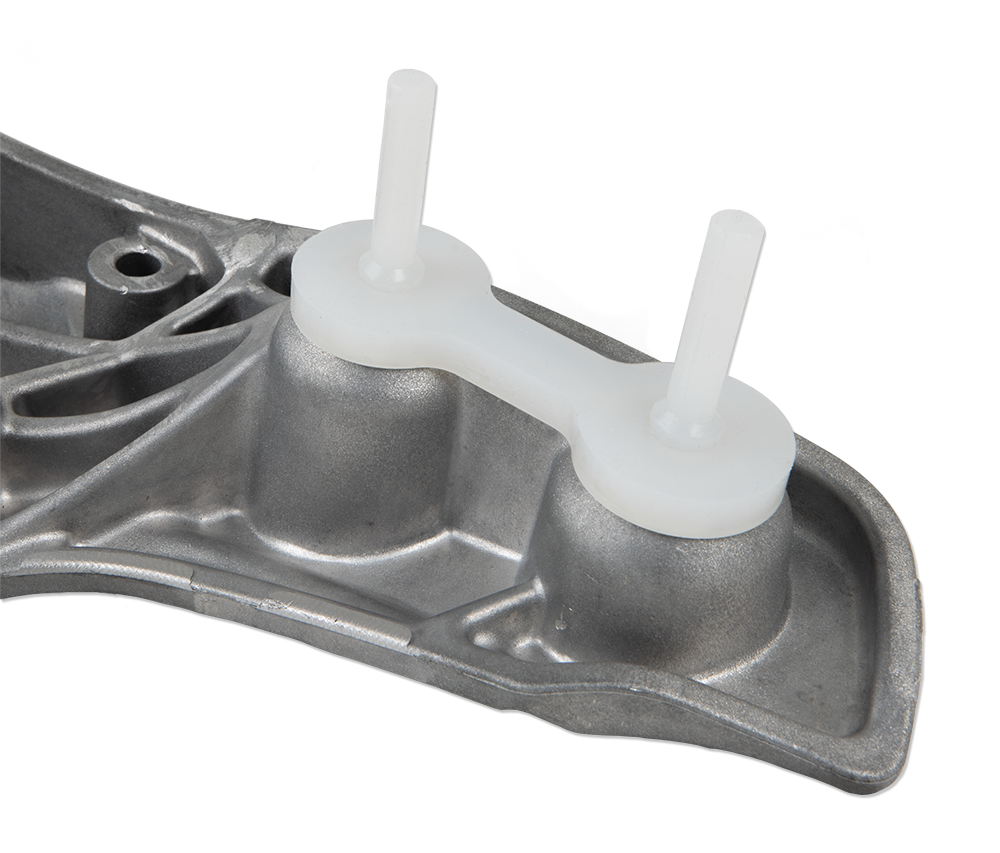

- Caps or Plugs Blowing Out: High temps result in a lot of pressure buildup that may be causing you issues with masking parts popping out. We've designed and developed various masking options, including our favorite cross-vent plug that releases pressure while also preventing blast and paint from covering up or entering the vent.

- Nothing to Cap Onto or Plug Into: For areas such as mating surfaces, you can either go with custom die-cut masking tapes or magnetic masking, which has become extremely popular over the past several years.

- Issues Hanging Parts: Conductive silicone is a go-to option for metal finishing processes that want to hang parts while maintaining conductivity.

- Time Constraints: Masking is typically one of the last things that's thought about. When timing is a big deal, your main options will be custom die-cutting and 1-week rapid prototyping to speed up the validation process.

Conductive Masking

Mating Surface Masking

Cross-Vent Plugs

Magnetic Masking

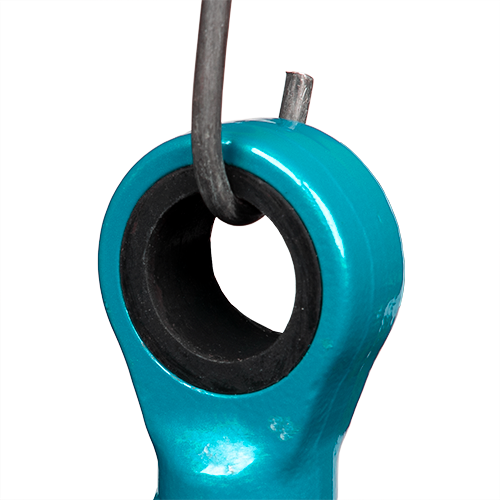

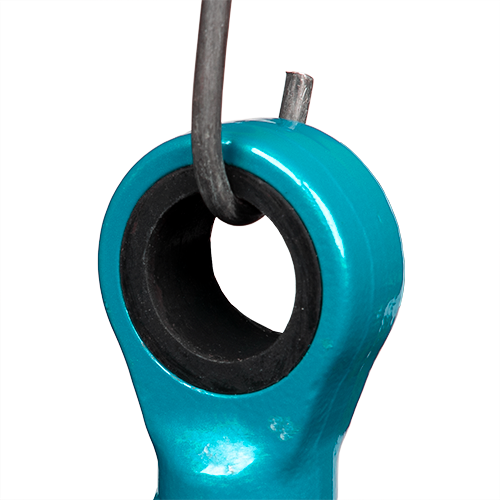

Masking Bores and Bushings - Masking Sleeves

Masking bores requires a masking solution that effectively seals out e-coat and powder coat, while also offering the ability to be reused to lower costs.

Echo specializes in engineering custom masking sleeves for your specific applications by factoring in a variety of different technical elements to ensure effectiveness, including sleeve thickness, durometer, silicone shrink rate, conductivity (for the cases where you'd want to hang a part by the sleeve), temperature resistance, and a handful of other factors that will play a significant factor towards whether or not the mask will work.

Magnetic Masking for Powder Coating

Magnetic masks replace the need for adhesive tapes, they're faster to install and remove, and they mask surfaces where you can't cap or plug. The silicone absorbs a lot of the high temperature, but because magnets aren't the most heat resistant, we've designed most of our custom masking solutions to be insert versions, giving our customers the ability to replace magnets and get more usage out of the silicone masks.

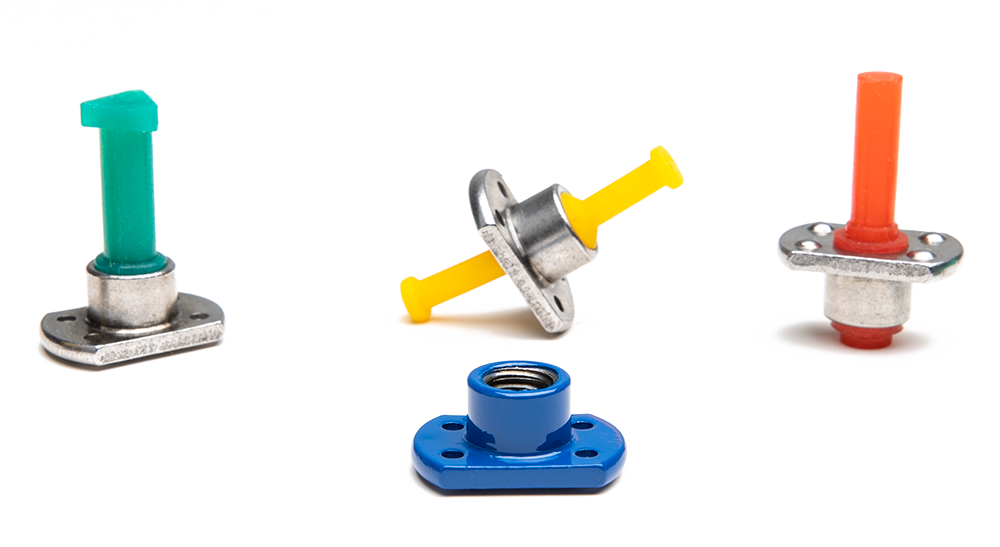

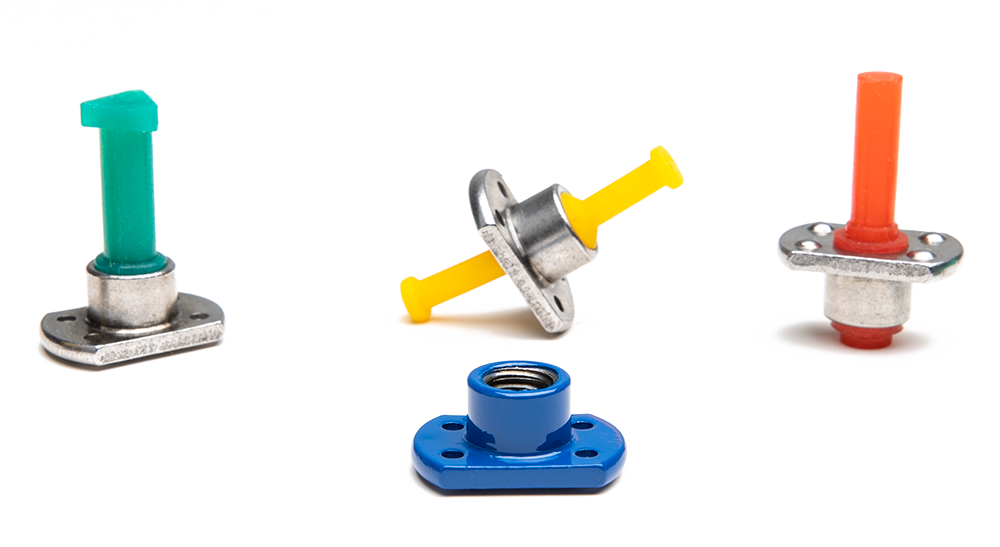

Weld Nut Masking Solutions

Weld nuts are common in the heavy machinery world. Echo offers a variety of different plugs used to mask off weld nuts' leading and exit threads, depending on if it's for a blind hole or through hole.

To learn more about the different ways to mask weld nuts and the different options we offer on our website, check out the link below.

OEM Direct Components

Echo Engineering also specializes in designing and manufacturing rubber and plastic OEM direct components. Our core tech expertise centers around Fastening, Connecting, NVH, and Sealing components.

Our Capabilities

- Design Engineering - In-house team of engineers that develop new designs and optimize existing ones to ensure products meet your requirements.

- Prototyping & Validation - Innovations in our prototyping and validation process are used to bring new products to life faster than ever.

- Tooling - Our engineers are experienced in choosing and optimizing tooling options for tight-tolerance requirements, both internationally and domestically.

- Manufacturing - We have over 50+ years of manufacturing experience, converting, die-cutting, and molding industrial automotive components throughout the vehicle.