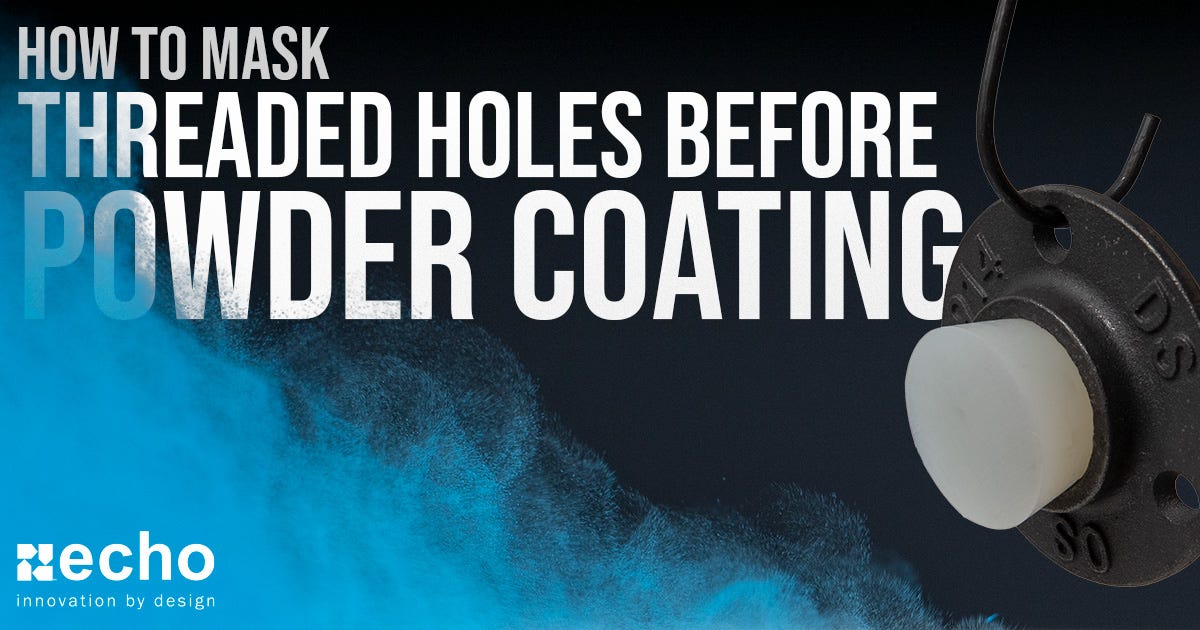

Comprehensive Guide on How to Mask Weld Nuts

-

By

Lee Lechner

By

Lee Lechner - Feb 27, 2019

Keeping a weld nut’s threads clean is vital when they’re about to be exposed to welding spatter from arc welding or about to go through powder coating, e-coating, wet paint, plating, or anodizing metal finishing processes.

Masking is especially important as re-tapping takes significantly longer to perform, taps have a higher cost when replacing them, repetitiveness may cause stress injuries, and, most importantly, re-tapping may damage the threads.

High-temperature masking plugs were designed to speed up your coating line’s efficiency, improve quality, and remove the need for re-tapping.

A push plug will be the most ideal for weld nut blind holes, while a pull plug works best for weld nuts with through holes. Whether masking a blind weld nut hole or a through-hole, creating a tight seal on the leading threads is extremely important in ensuring all threads are clean.

Masking Weld Nut Through Holes

Masking a weld nut through-hole will most likely require the use of a Pull Plug. These types of plugs have a longer length and are engineered to seal out paint from both sides of the hole. Below is our list of pull plugs specifically engineered for weld nuts that we recommend for your coating process:

Weld Nut Pull Plugs Designed for Metric Weld Nuts

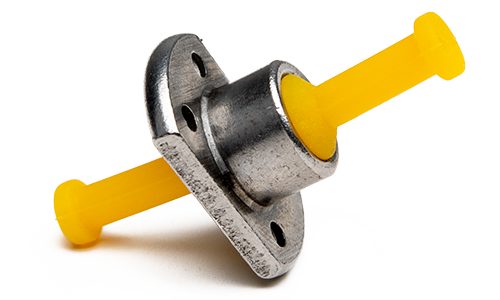

Weld nut pull plugs were designed and engineered to mask the leading and exit threads simultaneously on common metric threads, without having to worry about the plug blowing out.

Weld Nut (Double Chamfered) Pull Plugs

Weld nut double-chamfered pull plugs were designed and engineered to mask the leading and exit threads simultaneously on common metric threads.

These plugs mask more of the chamfered areas as well. When it comes to choosing between this plug, and the weld nut pull plug (above), generally it comes down to preference. These are a little harder to install and remove though.

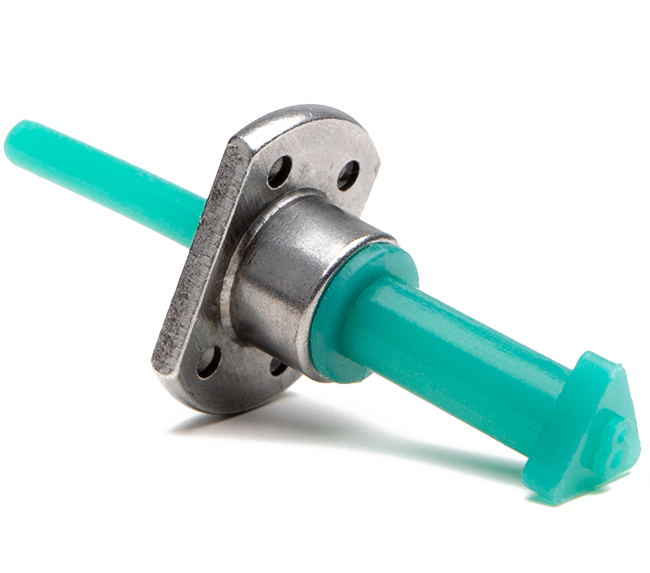

Leading Exit Pull Plugs

Another great alternative for masking the leading and exit threads of a weld nut is the Leading Exit Pull Plug. Again, these plugs are very similar to the Weld Nut Pull Plugs. Metal coaters generally go with the one they prefer most after sampling both out.

Chamfer Pull Plugs

Chamfer pull plugs mask the leading chamfer and threads and are much easier to install compared to the other pull plugs mentioned above.

Advanced Tip

If the powder paint that’s on your pull plugs is flaking onto the weld nut’s threads during the removal process, you may want to consider going with a custom version that uses Red Ironoxide Silicone material rather than the standard silicone. The ironoxide causes the powder paint to adhere to the plug, reducing the risk of flaking. The cons of going with red ironoxide silicone is that it can’t be color coded and it makes cleaning the plugs more difficult.

Masking Weld Nut Blind Holes

Masking a weld nut blind hole will require a push plug. Push Plugs are engineered to mask and seal the leading thread of common metric threaded weld nuts. The plugs that are available vary in design, but generally perform the same function. It tends to come down to personal preference. Below is a list of plugs available:

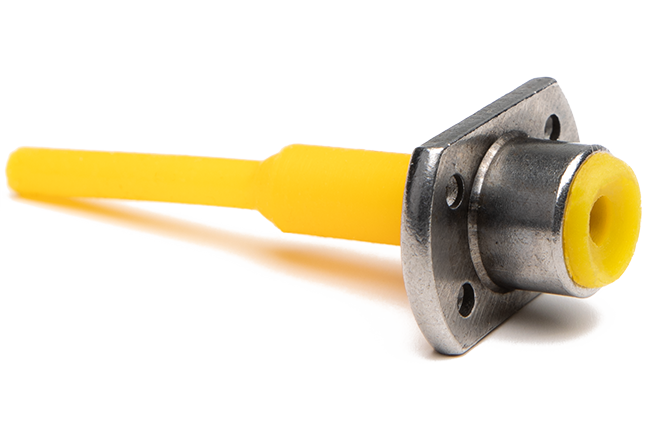

Silicone Leading Thread Push Plugs

Silicone Leading Thread Push Plugs are ideal for masking the leading threads as they’re easy to install and even easier to remove. The cons of this plug compared to the next option are that its longer handle may interfere with powder flow as it’s being applied (resulting in a feathered effect), and it sometimes requires a little twisting to effectively seal the leading thread.

Request a free weld nut plug sample kit:

Silicone Thread Plugs

Silicone Thread Plugs are also ideal for masking the leading thread of a weld nut. They’re easier to install and have a tighter seal compared to the leading thread boss plugs. The con to this plug is that they are much smaller, resulting in them being harder to handle and more difficult to remove (especially if you’re wearing thick gloves).

Silicone Tapered Push Plugs

Silicone tapered plugs are the most common plugs used to mask threaded blind holes. They work great as their tapered design allows them to create a tight seal, preventing any coating from getting into the threads, and they can even work in several different hole sizes.

The drawbacks to their simple design are that they won’t mask the chamfered area, and they can be difficult to remove due to their size.

Masking Threaded Holes in General

As long as you know the basics of masking a threaded hole, you’ll have no issue with finding the best way to mask a weld nut. This comprehensive guide was dedicated solely to the best masking options for weld nuts, but there are other options. To learn more about other masking options, check out our blog on How to Mask Threaded Holes.

Conclusion

Masking weld nuts is not a difficult task, it just comes down to choosing the best plug. If you’re not 100% sure what you should go with, please feel free to Request Samples or contact us with any questions you may have.