How Powder Coaters Can Improve Their Masking Operations in 2024

-

By

Lee Lechner

By

Lee Lechner - Dec 18, 2023

Powder coaters, as we step into 2024, it is the perfect time to reevaluate and enhance your masking operations for a more efficient and effective finishing line. Echo Engineering is here to guide you through some actionable changes that can revolutionize your masking processes and elevate your results. Let's dive in!

Benchmark Masking Operations:

In 2024, efficiency will be key to sustainable growth. Manufacturers are dealing with rising costs and wages, so it’s time to see where you stand now concerning the time and money spent related to masking.

Being cheap may be an option when you’re at home trying to paint your kitchen, but when time is money, you can’t afford to deal with the little things with high-volume operations. If you want to make an impact, here are a few areas to look into and track:

- Time spent masking per part versus labor costs

- Quality issues related to masking and/or lack of masking. Examples could include time spent retapping, tool expenses, rejected parts, etc.

Amount of reuses you’re able to get out of rubber masking caps and plugs - Time and money spent cleaning and reusing rubber masking caps and plugs

We also recommend looking into complaints from your production team and any injuries that may be caused by your masking operations, such as accidental cuts when trimming masking tapes or repetitive motion injuries

Switch Masking Materials:

When it comes to powder coating, the two most commonly used materials is green poly masking tape and silicone. Unfortunately, for a high-temp precesses, they don’t always get the job done. Luckily, there are excellent alternatives you can implement out the gate or explore with custom products.

Green Poly Tape Alternatives

- Rusty Red Masking Tape: If you’re running into issues with green poly baking onto the surface, the first option you may want to test out is rusty red poly tape, as it is rated slightly higher than green poly tape

- Glass Cloth Tape: For extreme temperatures and/or thicker coatings, we recommend trying out glass cloth tape as it is thicker and can withstand much higher temperatures than green poly.

Specialized Silicone Variations

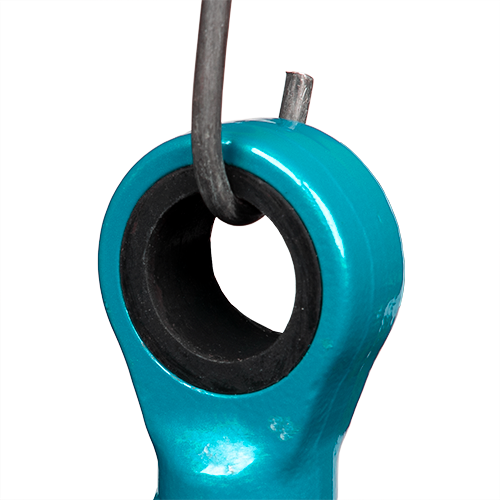

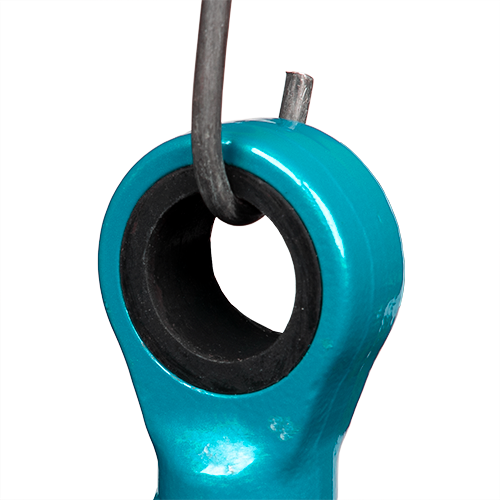

- Conductive Silicone: One area to look into is if there is a way of combining your hanging and masking into one. There are a few methods of doing this. The most popular method is by using conductive silicone. This is a high-temperature silicone with carbon black added into it, allowing the conductive charge to run through it to the part you’re painting

- Red Ironoxide Silicone: If you’re running into issues with paint flaking off of your masking caps or plugs, you may want to look into red ironoxide silicone.

- Low-Shrink Silicone: If you’re having issues with silicone sleeves shrinking (common when masking bores and bushings), then you’ll want to look into switching to low-shrink silicone.

Switch to Custom:

Every powder coating line is unique, and one-size-fits-all solutions might not be the most effective. Consider custom masking solutions to match the specific requirements of your components. Tailored masking solutions designed to fit your products perfectly, ensuring optimal protection during the coating process will not only save you time and money but also result in much more consistent finishes.

Custom solutions are also an excellent way of finding out how to prevent issues you might currently be dealing with, such as powder build-up, shadowing, plugs blowing out, etc. This is also a great time to look back into benchmarking your masking operations to get a better understanding of just how much time and labor custom solutions could save you.

Improve Inefficient Masking Designs

If you’re using masking right now, but getting inconsistent results, it’s time to start paying attention to the design and precision of your masking components. Opt for intricate and precise masking designs to ensure complete coverage and protection of specific areas. Echo Engineering's expertise in masking engineering can help you create custom designs that cater to the unique contours and shapes of your products, resulting in superior masking performance.

Use this time to understand your reject rate, time spent correcting mistakes (such as having to retap threads), and labor related expenses (such as time spent installing and removing an inefficient mask).

Invest in Training and Education:

Knowledge is power, and well-trained staff can make a significant difference in the success of your powder coating operations. Invest in training programs and documentation to educate your team on the latest masking techniques, materials, and technologies.

You don’t need to invest in an expensive production team to do this. This can be as easy as recording training with your phone and uploading it to a shared computer drive. Or writing up a process along with photos in a Word document.

Conclusion:

By incorporating these actionable masking changes into your powder coating operations, you can take a significant leap forward in terms of efficiency, precision, and sustainability. Echo Engineering is committed to supporting your journey towards excellence in powder coating, providing cutting-edge masking solutions that make a difference. Here's to a successful and innovative 2024 for your masking operations!