Powder Coating with Conductive Silicone Masking

-

By

Lee Lechner

By

Lee Lechner - Mar 18, 2024

Finding ways to ground a part before powder coating, it can be a pain, especially when you want to avoid finishing flaws caused by hooks. But what if there was a way to use your masking points?

In this post, we will explain why medium-to-large-scale powder coaters are shifting toward conductive silicone. We’ll cover what it is, where it is used, and some of its pros and cons in masking applications. So, let’s get into it.

What is Conductive Silicone?

When it comes to masking, conductive silicone is high-temperature silicone rubber combined with conductive carbon black (which has strong electrical conductivity).

When And Why Is It Used For Powder Coating?

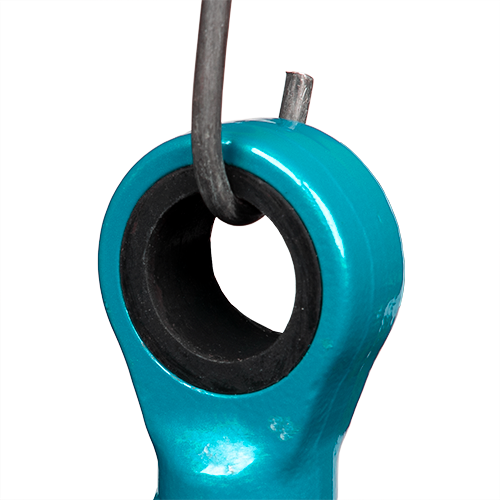

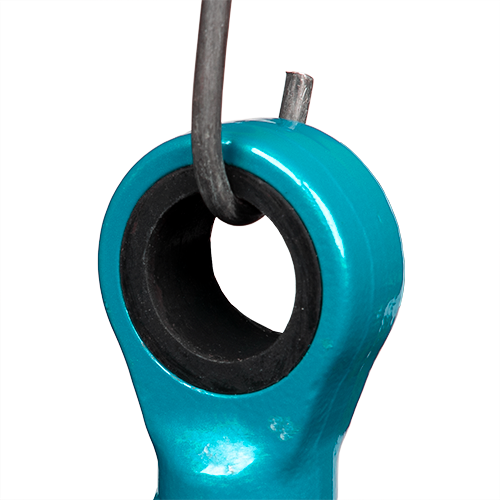

Conductive silicone has become an increasingly popular choice for masking off bores and bushings during powder coating. The main reason behind this is because it acts as the ground point for the part being coated when passing the charge through the mask is needed, reducing the risk of finishing flaws you might see from using hooks having direct contact with the part.

Ideal Masking Applications for Conductive Silicone

Bores and bushings are the ideal masking applications for conductive silicone, but this material can also be used as a ground point in countless other applications, such as shaft masking caps, mating surface plugs, and much more.

One area we’ve seen some interest in has been applying conductive silicone masking to the racking area rather than the part itself. This allows coaters to place the part being coated directly onto the rack rather than applying the mask and then hanging it. Designs like this, in theory, sound great, but you may run into issues with meeting tight tolerances and issues with the masking part coming off as you remove the part from the rack.

How To Test For Conductivity?

It is important to first ensure that the rubber masking you receive is actually conductive. The basic explanation of doing this is by applying voltage across the rubber piece an measuring the electrical current that passes through the rubber.

In order to do this, you’ll need either a multi-meter or insulation meter. At Echo, we specifically use an insulation tester.

Cons of Conductive Silicone

While conductive silicone continues to grow in usage with masking applications, the main drawback to the material is that it is reusability compared to standard silicone.

Extreme curing temperatures from the powder coating process will eventually result in conductive silicone degrading over time. The carbon black additives typically cause conductive silicone to degrade faster than standard high-temperature silicone, meaning these masks will need to be replaced slightly more often.

Conclusion

Conductive silicone masking is an excellent option for converting your masking point to a grounding point. These types of parts are typically custom-made to ensure a tight dimensional fit. We hope this post gives you a fundamental understanding of why powder coaters want to implement this material into masking designs.

If you believe a conductive silicone masking option might be a good fit for your project and process, please contact us by filling out the form below.