How to Mask Threaded Holes

-

By

Lee Lechner

By

Lee Lechner - Apr 5, 2017

How to Mask Threaded Holes

Having trouble keeping paint, rinses, or chemicals off threads? Cross-threading due to paint is a costly issue many surface finishers face, as re-work can require a great deal in time and resources. Choosing the correct plug to protect your threads will eliminate the need for thread chasers and taps!

A push plug will be the most ideal for threaded blind holes, while a pull plug works best for through holes. Whether masking a blind hole or a through hole, creating a tight seal on the leading threads is usually imperative to keeping all threads clean.

Masking Threaded Blind Holes

Masking a blind hole requires the use of a Push Plug. Your main objective here will be to create a tight seal on the leading thread(s). Below is our list of push plugs we recommend for your coating process:

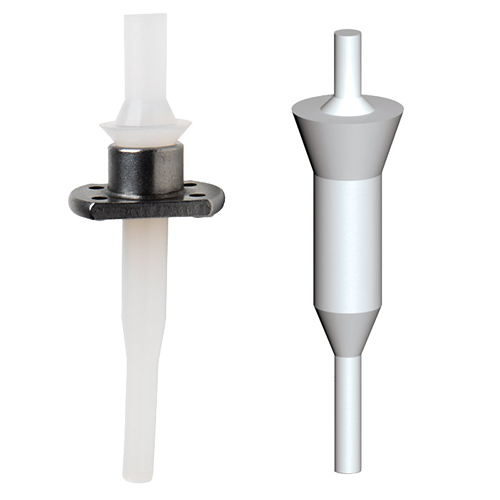

Rubber Tapered Plugs (Most Popular)

The most common solutions for masking threaded holes are rubber tapered plugs. They are easy to install, contoured to fit multiple hole diameters, and offer excellent sealing ability.

For most Powder Coating, E-Coating, and other high-temperature processes that exceed 350°F/177°C, you’ll want to go with silicone plugs, as they’re rated up to 600°F/177°C.

For most Plating, Anodizing, and other low temp processes below 350°F/177°C, you’ll want to go with EPDM plugs, as they don't leave silicone residue and have better chemically resistant properties compared to silicone.

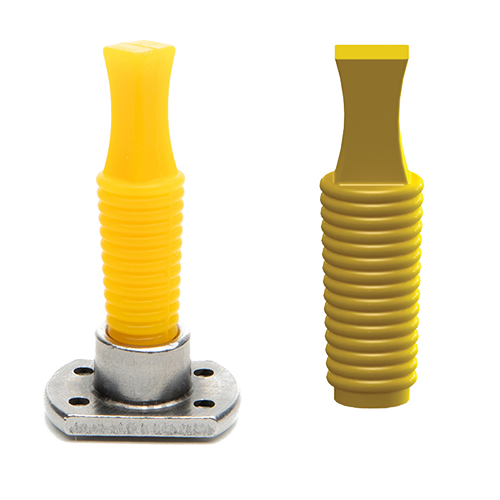

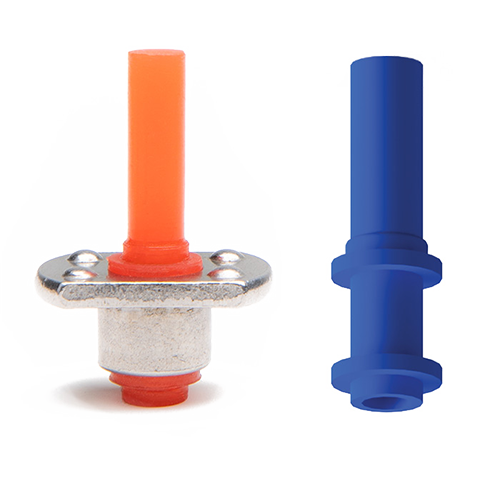

Ribbed (Flangeless) Plugs

Flangeless plugs are great for masking threaded holes (including the top thread) because the ribbed design helps with gripping the threads, to help prevent blowout.

How to Choose the Correct Size Plug

Step #1: Determine the ID (Internal Diameter)

Method #1 - Use Thread Charts

One method if you don't have the ID (internal diameter) dimensions handy is to use a thread chart of common Standard and Metric thread sizes and look for the (Female) Internal Minor Diameter

Method #2 - Use a Digital Caliper

You could also use a digital caliper to measure the thread's ID, similar to what is shown in the image. We measure the Internal Minor Diameter because that is where a tapered plug with grab onto.

Keep in mind that you want to measure the INSIDE of the threaded hole, not the top of the hole.

Step #2: Choosing the Correct Size Plug

Picking the correct size plug is simple. Match the Internal Minor Diameter to the middle diameter of the plug you want to use.

If you're not sure what the middle diameter of a plug is, you just need to simply calculate: (Top Diameter + Bottom Diameter) / 2

Masking Chamfered Blind Holes

When you need to mask the chamfered area of a threaded blind hole, a push plug that incorporates a flange or rib will be necessary. Below is our list plugs we recommend for these cases:

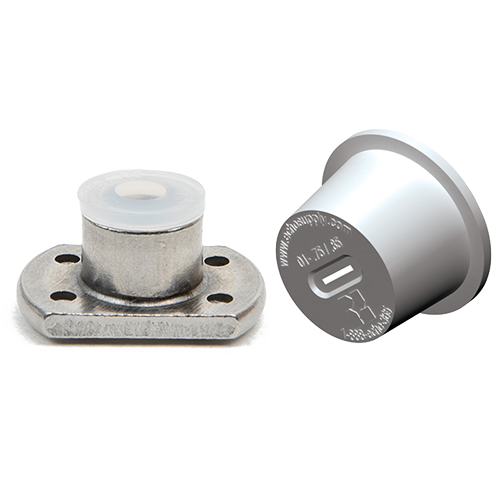

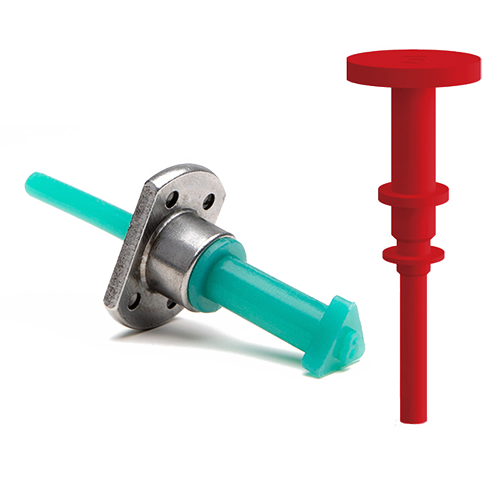

Silicone Leading Thread Boss Plugs

A great plug to use to mask the chamfer of a threaded blind hole is the Silicone Leading Thread Boss Plugs (pictured below). These plugs were engineered to be extremely easy to install (see gif below) and remove, and also includes a second flange to lock the plug in place.

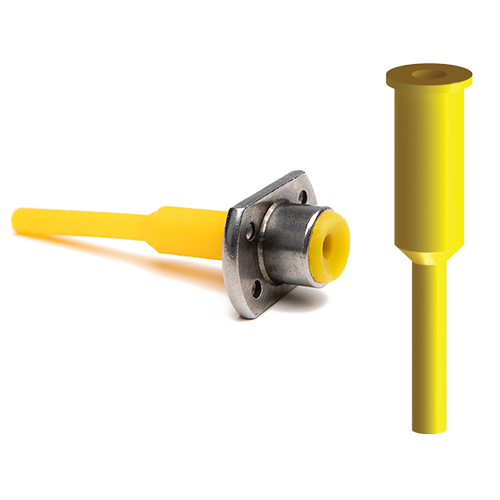

Thread Plugs

Another great option to mask the leading thread is with a thread plug (shown below). They’re easy to install and less intrusive when you’re applying your powder coat, as it does not have a long handle like the silicone leading thread boss plugs (decreasing the likelihood your part will experience shadowing).

Vented & Non-Vented Tapered Plugs

The flange on these plugs can be used to mask the leading thread chamfer or mask the surrounding grounding surface. The flexible material allows for a snug fit. These will also cost less than standard tapered plugs due to less material.

The vented versions have a small slit designed to allow pressure to release when it builds up, yet keep moisture and paint out. The drawback of these two plugs is that they can be more difficult to remove.

Masking Through Holes

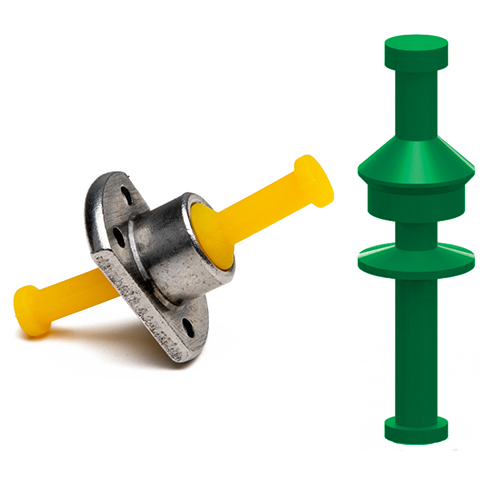

Masking a through-hole will most likely require the use of a Pull Plug. These types of plugs have a longer length and are engineered to seal out paint from both sides of the hole. Below is our list of pull plugs we recommend for your coating process:

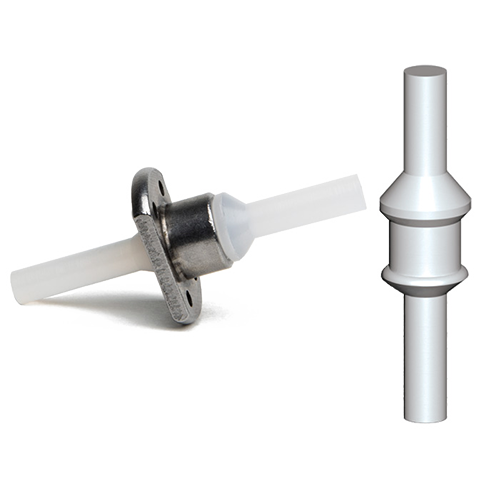

Standard Rubber Pull Plugs (Most Popular)

Rubber pull plugs are the most commonly used solution to mask threaded through holes. For higher temperature processes, like Powder Coating & E-Coating, you’ll want to use silicone pull plugs.

For lower temp processes, like Plating & Anodizing, you’ll most likely want to use EPDM pull plugs.

How To Correctly Size Pull Plugs

Once you know the ID of your threaded hole (use instructions mentioned earlier) you will choose a plug that is oversized by .030".

Example: We have a threaded hole that has an Internal Diameter of .2675". Using the logic above, we will add .030", which equals .2975". You'll want to find a pull plug where the plug's diameter is close (or possibly a little bigger than .2975").

In this case, we would recommend trying out our 01-0020312-04SIL pull plug (which has a diameter of .312"). This is a little larger than what we were looking for, but luckily that means you'll have a tight seal (which is ideal for E-Coaters). If you're a Powder Coater, you may want to try out the 01-0020281-04SIL pull plug. It's a little smaller than what we were looking for but is bigger than the hole ID, and it'll be easier to install/remove.

Masking Leading Chamfer

If your biggest concern for your threaded through holes is keeping the leading chamfer (countersink) area clean, there are plugs designed specifically for your needs. These plugs include:

Chamfer Pull Plugs: Ideal for masking leading threads and chamfers. These plugs are made with a softer duro compared to the others, giving them a slightly better sealing advantage.

Flange Pull Plugs: These also do a great job at masking off the leading thread and chamfer area. The tapered top also helps decrease/prevent powder build-up around the plug

Masking Leading AND Exit Threads

When it comes to masking threaded through holes, it’s vital to keep the exposed leading and exit threads clear of coating. Luckily, there are a variety of plugs designed for this specific purpose. These plugs (pictured below) include: