Powder Coating Masking Expertise

Powder coating masking solutions is where Echo's engineering capabilities really show. On top of our vast selection of high temp caps, plugs, tapes, and die-cuts, Echo also offers hanging hooks and extensive custom solution capabilities primarily used on finishing lines of some of the world's most well known heavy machinery, automotive, and powersport manufacturers.

Custom Molded Masking Solutions

Our engineers have designed thousands of custom rubber masking solutions used during powder to speed up their production, improve quality, and reduce costs.

We've seen it all, from powder coat building up around areas, overspray, leakage, high-temperature ovens, caps/plugs blowing out, and coaters having to retap threads.

Components We Specialize in Masking

- Threaded Holes

- Brake Calipers & Brackets

- Frames/chassis

- Mating Surfaces

- Bolts

- Bores

- Suspension Components

- Wheels

- Control Arms

- Outdoor Lighting Components

- Axles

- Pivot Points

- Tubes

- Grounding Studs

- Weld Nuts

- Welding Points

Examples of Echo's Engineering & Manufacturing Capabilities

Conductive Silicone

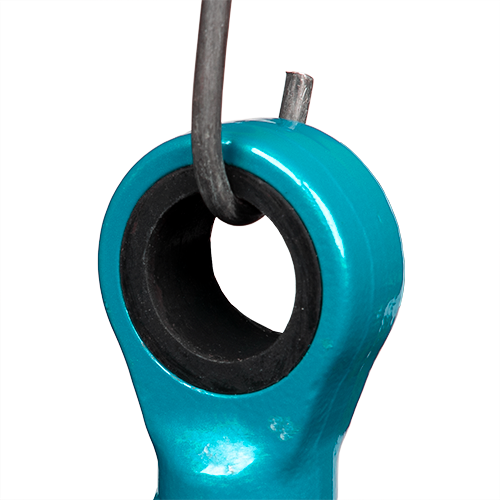

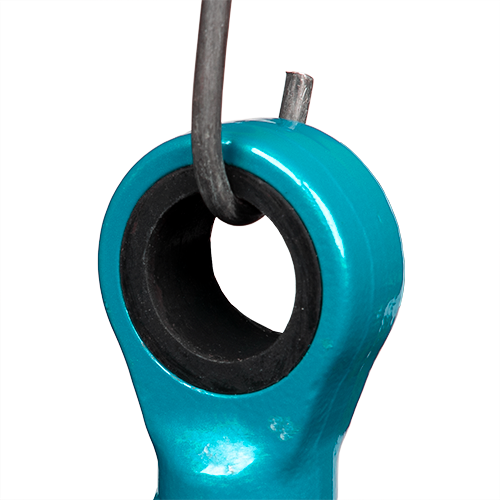

Overmolded Plugs

Magnetic Insert Masking

Cross-Vent Masking

Echo Offers 1-Week Molded Rapid Prototype Masks

Rubber Materials for Powder Coating

High-Temp Formulated Silicone

The majority of Echo's masking caps and plugs are made from a custom formulated silicone meant to withstand temperatures up to 600F

Conductive Silicone

Conductive silicone is commonly used by powder coaters when they need the charge to pass through a mask, rather from metal-to-metal contact (like from a hook)

Red Iron-Oxide Silicone

Red iron-oxide silicone is great for when paint/powder flaking is an issue. Due to the iron-oxide in the silicone, the powder will adhere more to the mask

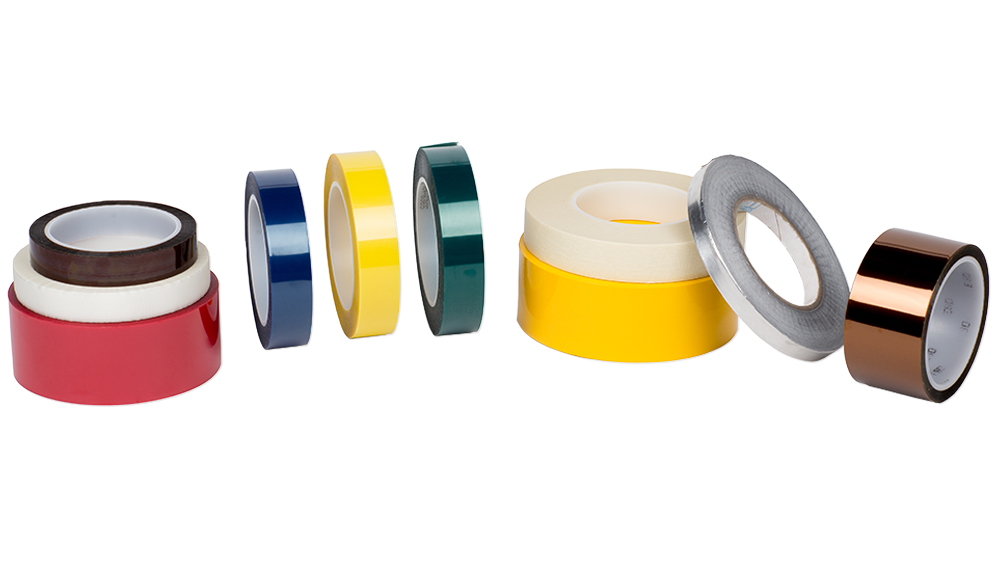

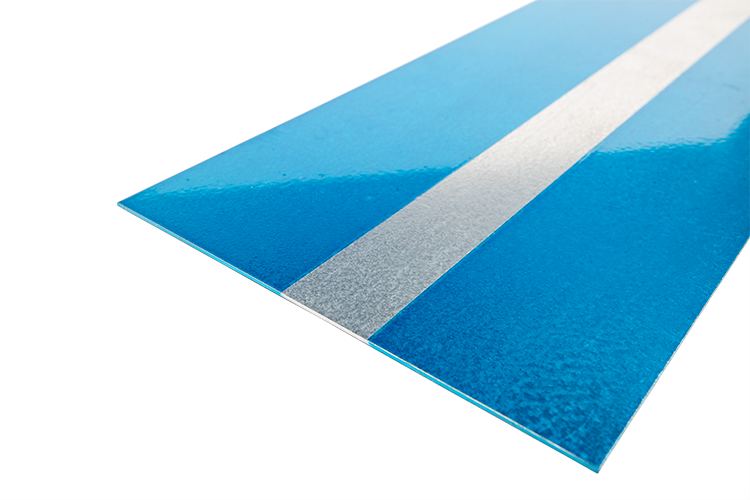

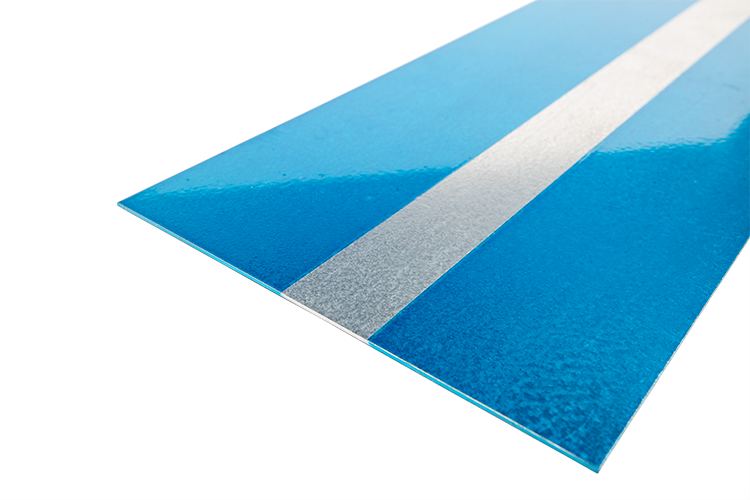

Masking Tapes & Die-Cuts

Masking tapes used during powder coating need to be highly heat resistant, leave no residue, form an effective seal, and leave a clean line your customer is looking for.

Echo specializes in high-temperature tapes and die-cuts designed specifically for Powder Coating. Our team is equipped to recommend the best tape material for your needs and engineered custom die-cuts to help speed up your process and improve overall quality.

Shop Masking Tapes

Why Should You Reach Out?

- Your current masking solution is failing

- You're having to retap threads

- You have a high % of rework

- Caps/plugs are blowing out due to heat and pressure build-up

- You're wanting to speed up your masking process to lower costs

- You're manually cutting tape

- You want to rapid prototype a new masking solution

- You're looking for a way to hang parts by a mask, rather than metal-to-metal