Automotive Underbody / Underhood Solutions - Design Engineering & Manufacturing

Echo Engineering is highly experienced in working directly with OEM and tiered automotive manufacturers by providing die-cut, rubber molded, and plastic molded solutions. Our customers range all the way from engine & cooling system manufacturers to the biggest electric vehicle makers in the world.

Echo's Underbody / Underhood Solutions

Underbody / Underhood Plastic Injection Molded Solutions

Echo Engineering and Ammex Plastics have been investing heavily with the automotive fastening market by developing a library of different designs, hiring plastics and process engineers, adding additional presses, and purchasing new testing and measuring devices.

We are experienced in designing and manufacturing a variety of different automotive clips used on HVAC lines, brake lines, wiring harnesses, etc.

Echo and its sister company Ammex Plastics have been designing and supplying hose connectors for 20 years. We have shipped millions of components and run at a PPM rate of <2. Our experience and technical expertise help to spot problematic designs early and deploy the best solution to shorten PPAP timelines and maximize part quality.

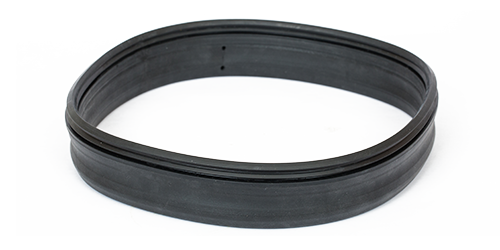

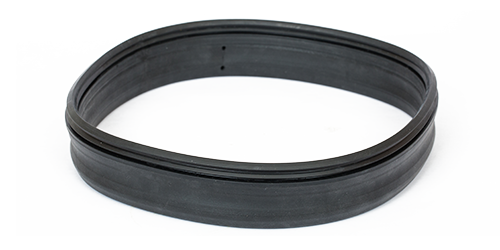

Sealing Solutions for Underbody / Underhood Applications

Echo's experience with overhead die-cutting and compression molding set up the groundwork with our expertise in custom automotive sealing components. In order to manufacture seals to OEM specs, you must have an in-depth understanding of material modifications, manufacturing processes, and testing methods. This is what Echo Engineering provides, from start to final production delivery.

Examples of Echo's Automotive Sealing Experience

Air Intake Seal

Tail Light Seal

Chargeport Caps

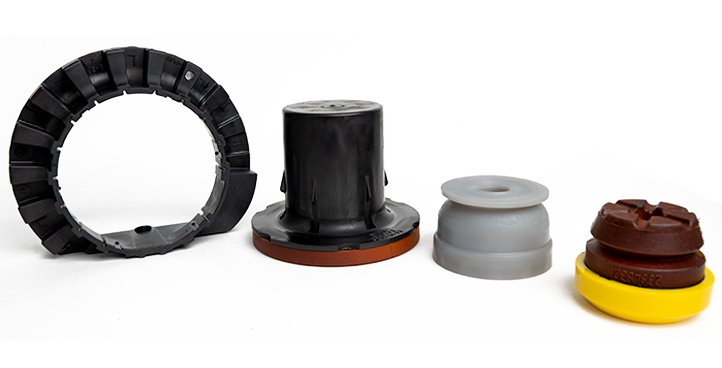

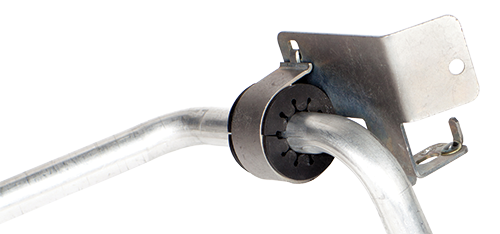

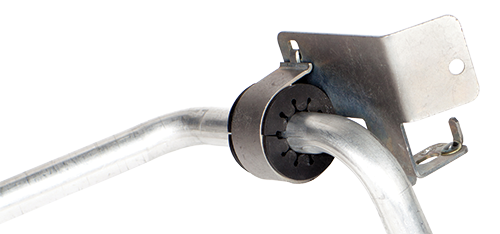

NVH Solutions - Compression Molded Grommets, Spacers, & More

The undesirable sound of a metal tube rattling in a car does not exactly scream quality. This is where Echo's years of designing and manufacturing molded rubber components to reduce automotive NVH comes in. Whether it's custom formuating a rubber material to prevent galvonic corrosion, testing out a variety of different shore hardnesses, or designing a custom grommet for your application, Echo has the engineering, molding, and testing expertise to bring your project to life!

Examples of Echo's Custom Molded NVH Solutions

HVAC Tube Grommets

Rubber Spacers

Bracket Insert Grommets

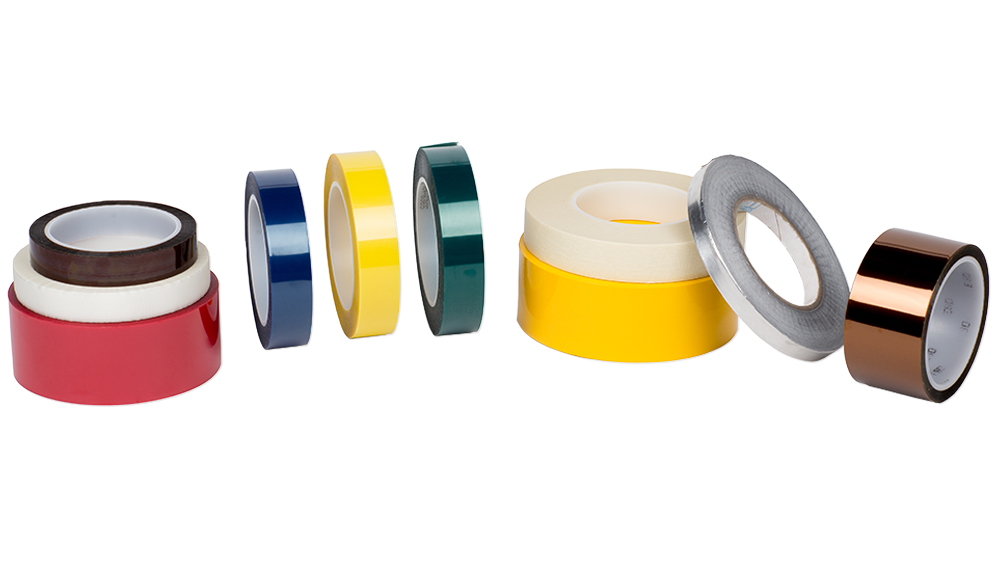

Top Automotive Underbody / Underhood MRO Solutions

Industrial Masking Experts

At Echo, we specialize in masking solutions used during a variety of automotive finishing and coating processes. Industrial coating processes are complex and can be the biggest bottleneck for our customers. What we do at Echo is help you solve your masking needs, speed up your masking operations, and lower quality-related issues.

We use innovative engineering methods, a new proprietary prototyping process, and testing methods to solve some of the most complex masking related problems in the industry.

Examples of Echo's Custom Automotive Masking

Custom Wheel Masks

Custom Brake Caliper Masks

Steering Knuckle Masks

Industrial Protective Solutions

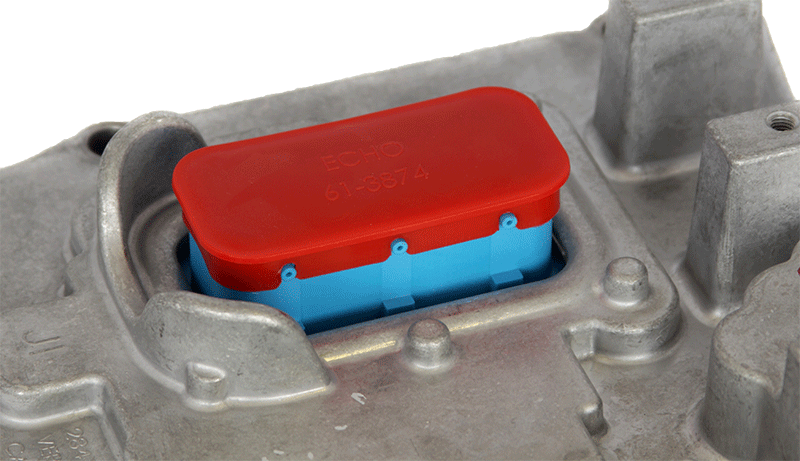

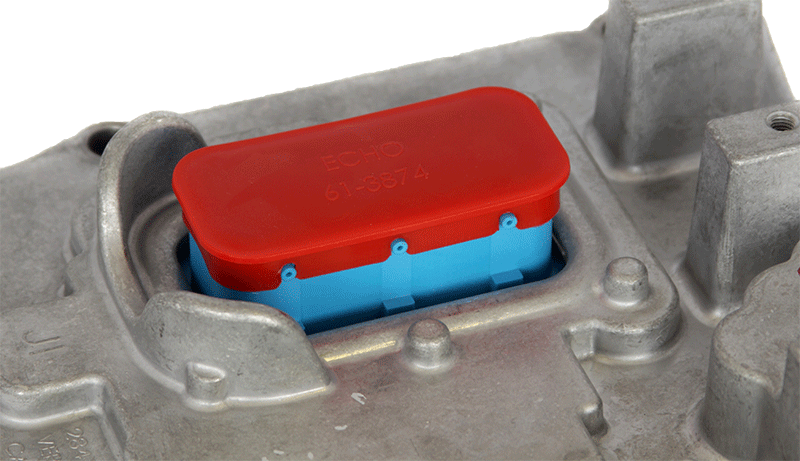

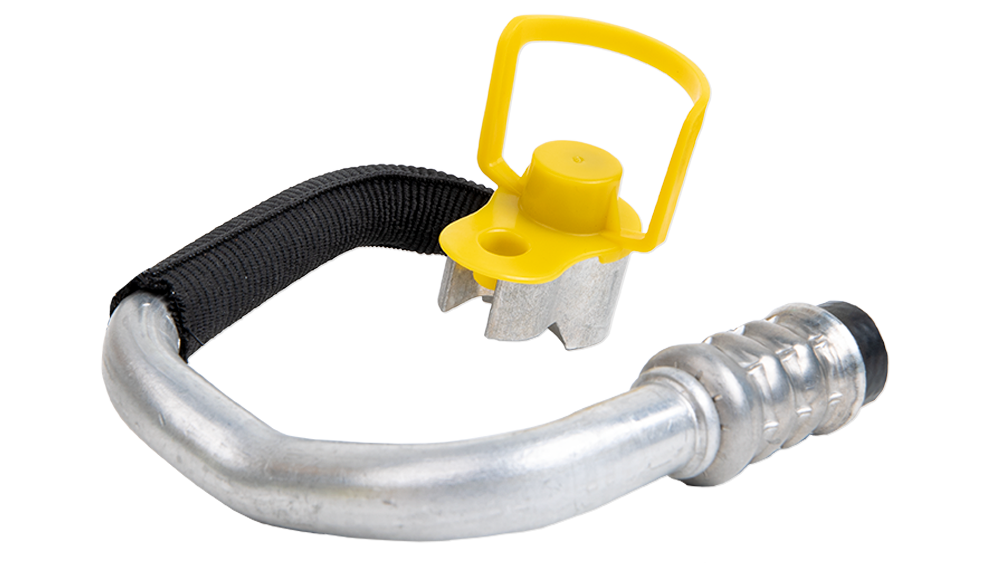

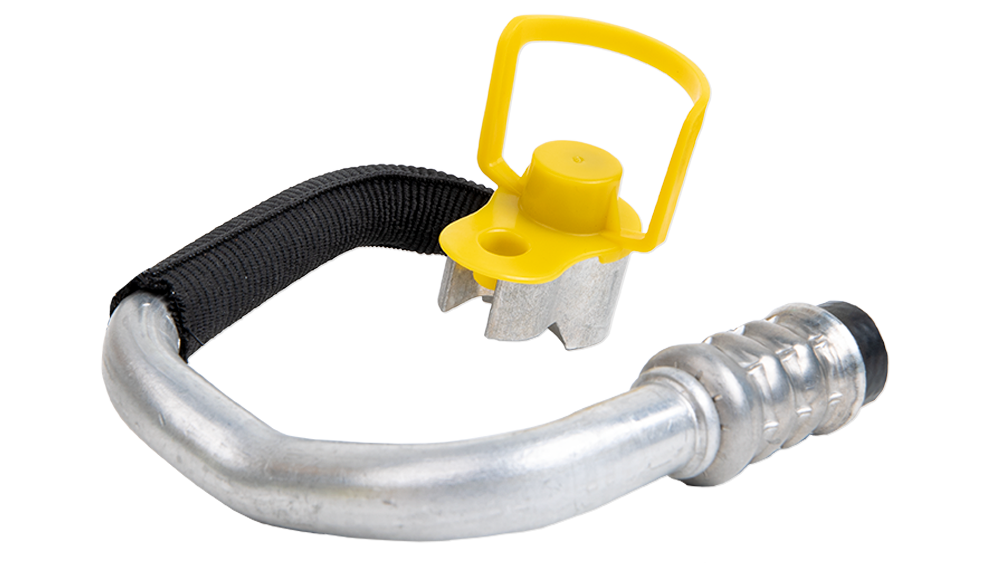

Quality is everything in the automotive industry. Echo specializes in a variety catalog and custom protective caps and plugs used to protect vital components during the shipping and storage stage of our customer's products. Below are a few of the many projects we've developed in the past.

Shower Caps / Dust Covers

Engine Control Module Caps

Fluid Routing Line Caps

Catalog Masking Solutions

Related Resources

The Future of Noise Reduction Inside Electric Vehicles

In this post, we take you through some of the newest technology and trends that are becoming increasingly adopted throughout the industry to get closer and closer towards sound-proofing the interior over electric vehicles.

Automotive NVH - The Science Behind Sound

If you are an NVH Engineer, you need to have a full understanding of exactly what it is that you are working to combat or improve. In this post, we'll take you through the basics of sound, its impacts on the automotive industry, and briefly touch on psychoacoustics.

Engineering Design - Plastic Clips & Fasteners

Engineering a plastic part to replace a metal component requires expertise in design, material, tooling, injection molding, and validation testing. In this post, we're going to explore some of the designs that become the go-to for tier-1s and OEMs over the years.