Injection Molded Hose Adapters, Connectors, and Fittings

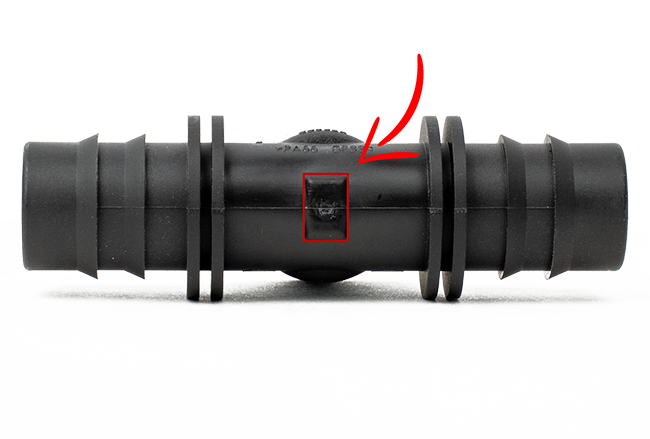

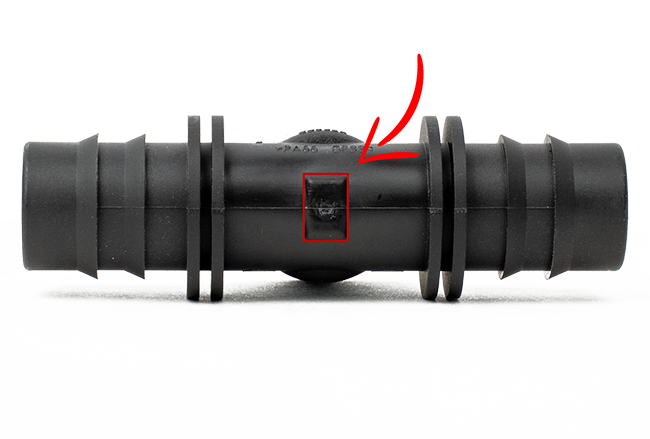

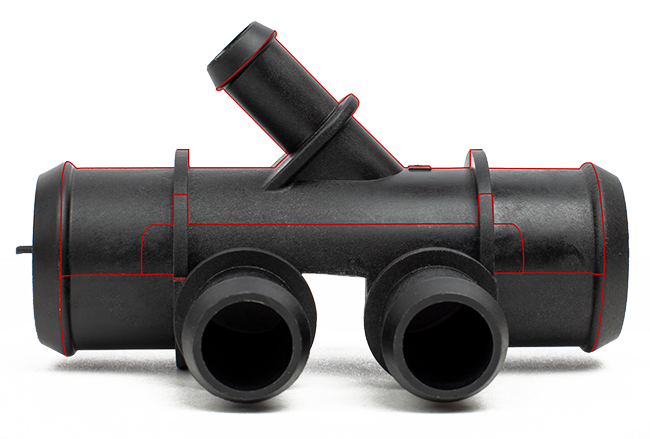

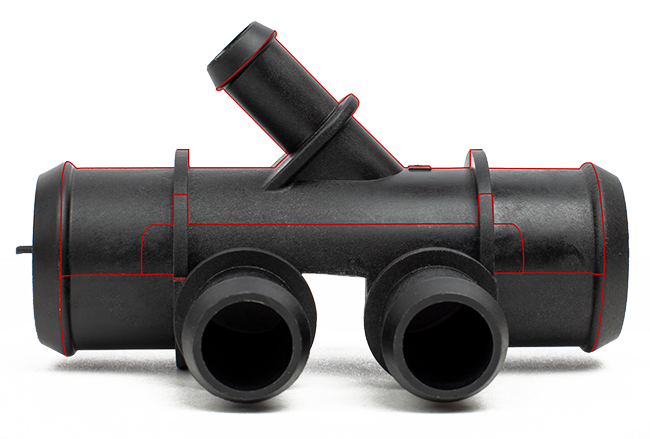

Echo specializes in designing and manufacturing complex injection molded hose connectors, adapters, and fitting used primarily in automotive applications (such as battery coolant lines, engine coolant lines, washer pumps, and HVAC lines). Our expertise within this market is rooted in our deep understanding of manufacturability and tooling factors related to wall thicknesses, sharp transitions, tight tolerances, gate location, and material selection.

We have been doing this for well over 20 years and continue to ship millions of components and run at a PPM rate of <2. Our experience and technical expertise help to spot problematic designs early and deploy the best solution to shorten PPAP timelines and maximize part quality.

Capabilities

- Product Design Engineering

- Tool Design & Optimization

- Material Selection

- Design for Manufacturing

- Mold Flow Analysis*

- Surface Roughness Measuring*

- Additional Testing Capabilities Available

* = Third Party

Manufacturing Processes

- Injection Molding (60 - 610 Ton)

- Insert Molding

- Over-Molding

- Prototyping

Common Materials

- Polyamides / Nylon (PA)

- Polyphthalamide (PPA)

- Polypropylene (PP)

Engineering Review

Design Review

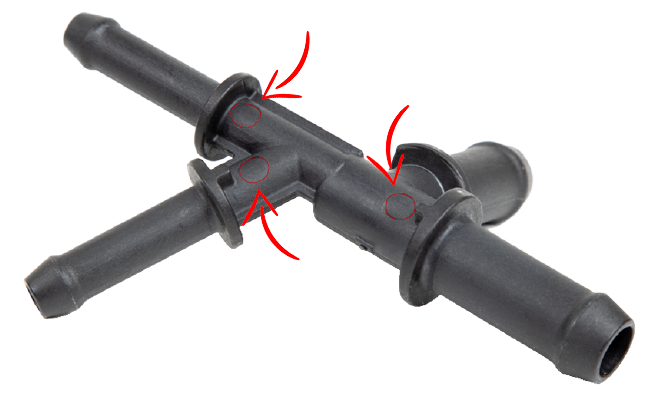

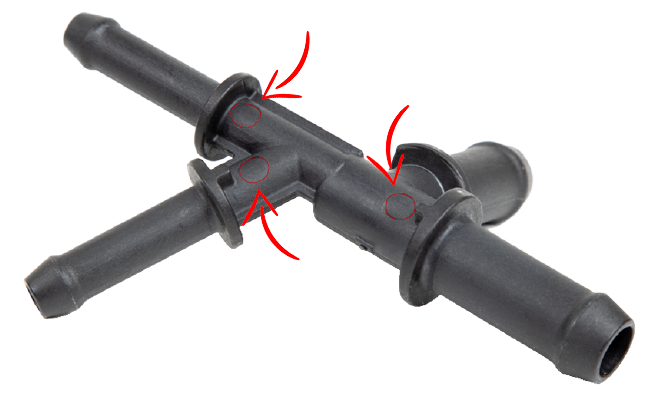

Engineering design is one of the most critical aspects of your project. Our engineers will review elements of your design, such as wall thicknesses, sharp transitions, knife edges, tolerances & technical specs, gate locations, and material selection in order to ensure manufacturability feasibility that will meet your requirements.

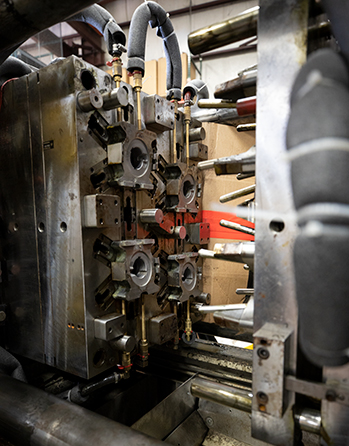

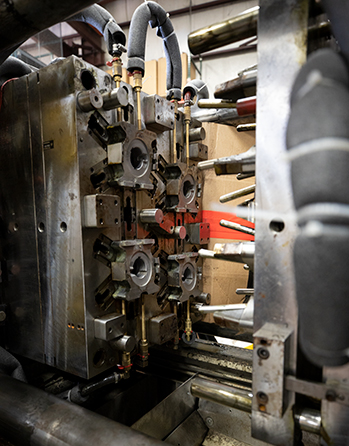

Tooling

Quality tool engineers can balance melt flow and reduce cycle times with hot runner systems, increase cooling capacity with copper cores and forced air flows, and produce precise round parts with out-of-round tools.

Depending on the part design, material flow, and residual stresses, sometimes it takes an out-of-round tool to produce precision round parts like fluid connectors. Below are examples of what needs to be factored in towards injection molding a hose connector that will meet tight tolerances.

Gate Location & Design

Parting Line Location & Feasability

Ejector Pin Location(s)

Why Choose Echo Engineering?

Echo Engineering has been designing and supplying hose connectors for over 20 years. We have shipped millions of tight tolerance components and run at a PPM rate of <2. Our experience and technical expertise help to spot problematic designs early and deploy the best solution to shorten PPAP timelines and maximize part quality.

If getting your barbed hose connector done right is your primary driver, reach out to Echo for an up-front and in-depth design feasibility analysis.

Learn More About Injection Molding Connectors

Checkout our recent post where we went more in-depth on the critical design elements involved in the design and injection molding process of automotive barbed hose connectors.

Bonus Material: We also included what it takes to mold with glass fiber additives and the pros and cons of single barb vs. multi-barb.