How to Mask Bores & Bushings

-

- Apr 8, 2020

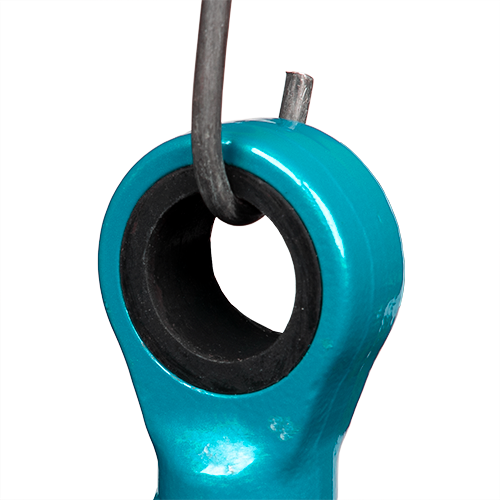

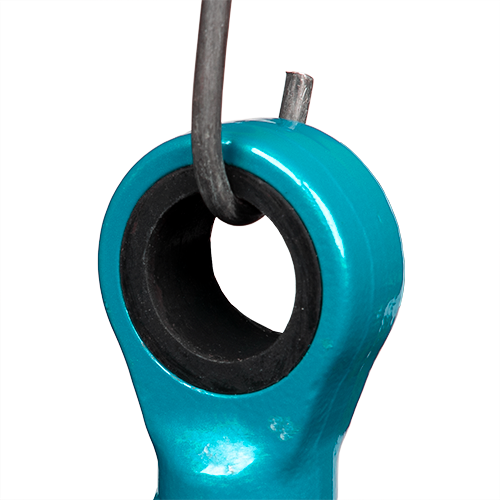

Masking Bores & Bushing Before Painting, E-Coating, or Powder Coating

Over the years, industrial coaters have tried masking bores and bushings using tapes and die-cuts (which are inconsistent & take way too long to install, pull plugs (which cost more than needed), and even cardboard rolls (resulting in leakage and a ton of quality issues).

One method heavy machinery and hydraulic cylinder manufacturers have converted over to is by using high-temperature masking sleeves. But, in order to successfully make the switch, several factors need to be taken into consideration. In this post, we take you through what it takes to design the best bore/bushing masking sleeve for each type of coating process.

Using Masking Sleeves during Powder Coating

The name of the game here is high-temperature resistance. Luckily, powder coating is easier to prevent leakage quality issues compared to e-coating. There are three critical aspects that are factored in towards making a solid working masking sleeve: Length, Oversizing, & Thickness. We go into more detail later.

Outside of the three elements, another element that you'll need to choose from is what type of silicone you'll want to use. The two materials powder coaters looking to mask bores and bushings typically use the most: Low-shrink silicone and conductive silicone.

Low-Shrink Silicone

If you're looking for a sleeve that will be used solely to mask (and not hang from), then low-shrink silicone will be the way to go. This will be the material you're able to the most usages out of. We've seen customers get 10-20+ usages out of them, depending on how high the temperature gets & how long they're exposed.

Conductive Silicone - Hanging Parts Through The Sleeve

Using conductive silicone is an excellent way for powder coaters to mask bores and bushings while also be the grounding point for the part being coated.

This material is created by adding carbon black into the silicone, making it conductive. The only drawback will be, eventually the conductivity dwindles down after multiple usages, and will need replaced more often than what you'd get with a high-temp low shrinkage silcone.

Using Silicone Sleeves during E-Coating

Masking bores and bushings during an e-coat process is more complex due to the paint's ability to leak into the smallest of crevices. Because of this, few extra design steps must be put in place for a successful mask.

Engineering Design

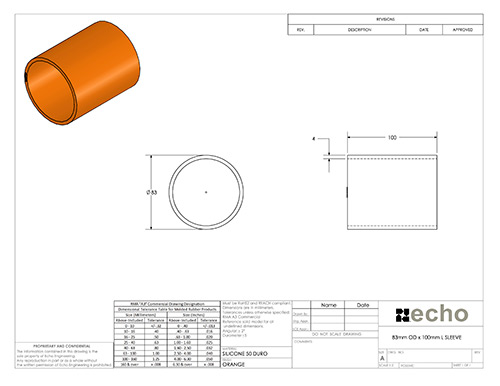

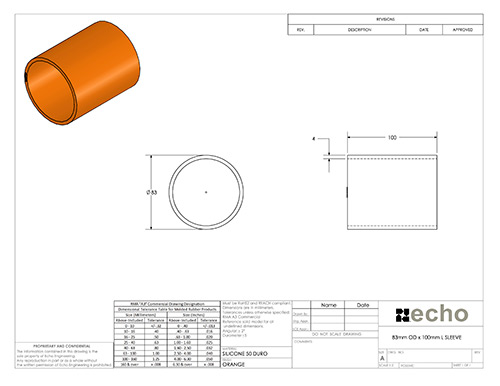

The three critical aspects of engineering the best sleeve for your bores and bushings will be:

- Length - The sleeve will need to be oversized so that it masks through both ends, reducing the risk of installation error

- Oversizing - In order to produce a solid seal, the sleeve's outside diameter will need to be oversized in relation to the bore/bushing's inside diameter

- Wall Thickness - On top of determining the best durometer of the silicone to use, you'll also need to ensure the sleeve is thick enough to maintain it's round shape after being installed

Material & Durometer

If you want to get multiple uses out of the sleeves, you'll need to use a low-shrink silicone to avoid shrinkage, resulting in paint leakage. Unlike powder coating and wet paint, you won't be able to get as many uses out of masking sleeves as they'll eventually shrink just enough after a few uses.

Another option to consider would be EPDM. It is a lower-cost/gram material, but you will most likely only be able to get 1 use from each sleeve when you put it through e-coat.

In order to keep the sleeve firm enough to maintain its shape, while also producing an effective seal, the silicone material will need to be right around 50-55 durometer.

Conclusion

So, if you're needing to mask a bore or bushing on your finishing line or you're looking at getting away from the inconvenience of using tapes and die-cuts, you'll want to some form of a masking sleeve, whether it's low-shrink silicone, conductive silicone, or EPDM (for low temperature).

If you have any questions, want us to review your current project, or you'd like to talk with one of our engineers, fill out the form below and we'd be happy to chat!