Automotive NVH (Noise Vibration Harshness)

- By Echo Engineering

- Jan 8, 2019

Noise Vibration Harshness (NVH)

NVH (Noise, Vibration, and Harshness) is the measurement, study, and modification of the noise and vibration characteristics of vehicles. Engineers must constantly work on combating the noise (what you hear), the vibration (what you feel), and the harshness (the effect bumps have on the car’s cabin) that impact a consumer’s experience when riding in an automobile as well as threaten the vehicle’s durability. Sources of NVH are found inside and outside of the vehicle and examples include:

- Cooling Fans

- Transmission

- Panel Holes

- Fluid Routing Lines

- Doors

- Brakes

- Alternator

- Road Noise and Wind

- Actuators

- Mounting Brackets

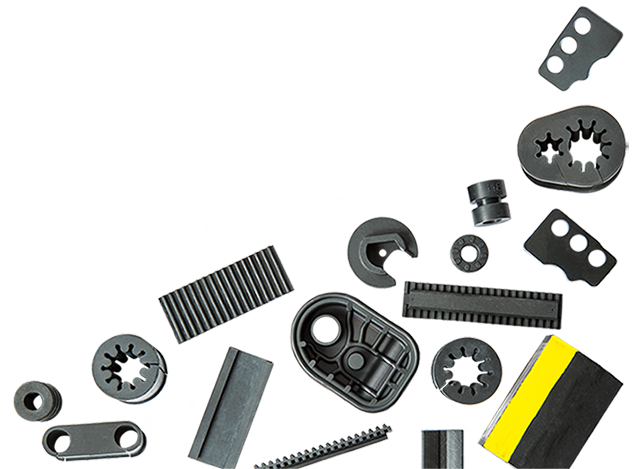

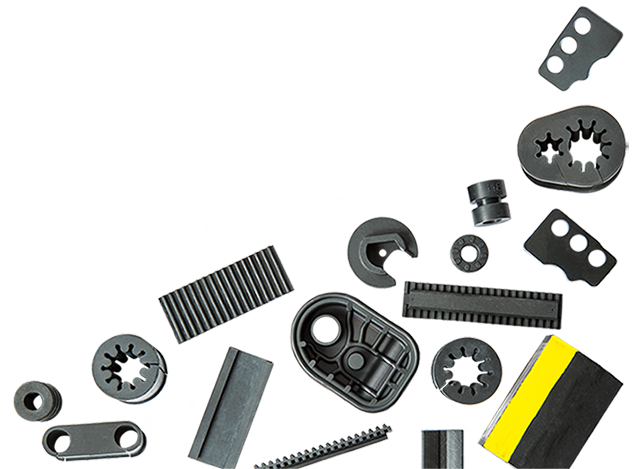

Rubber is an ideal material for NVH parts due to its high density that allows it to easily absorb sound and vibration – and reduce vibration transmission from one rigid vehicle component to another.

NVH parts and products for noise and vibration dampening, as well as shock absorption, are often found in a vehicle’s fuel system, HVAC system, brake system, and chassis.

In today’s market, NVH control is a consumer expectation in the majority of passenger vehicles as the customer’s preference continues toward comfort and safety. Additionally, the demand for automotive NVH components continues to grow due to the global increase in automobile production, especially in emerging economies.

In automotive design, NVH is managed by minimizing the transfer of undesirable noises and vibration into the passenger area. This is accomplished by the use of noise and vibration absorbing and damping NVH parts which improve the comfort, performance, and safety of the vehicle. Automotive NVH products are often small components that are manufactured from rubber, foam, or other materials.

Also, the need to address NVH is expected to continue to climb as the electric vehicle market grows given these vehicles do not have the traditional engine noise and vibration that often cancel out other squeaks and rattles.

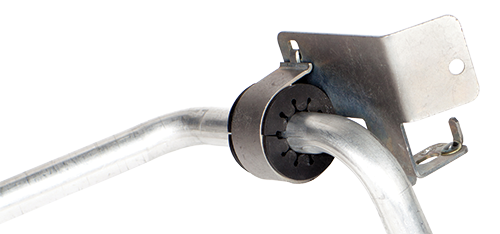

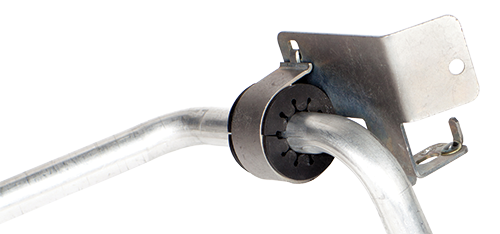

Reducing NVH On Fluid Routing Lines

Custom rubber tube grommets reduce NVH by preventing metal to metal contact and limiting the movement of metal tubing. These type of grommets usually include custom-designed internal ribs that give the fluid routing line assemblies the ability to be flexible, while significantly reducing the amount of vibration that occurs. They typically also need to be made with a custom non-conductive EPDM rubber formulation to aid in the prevention of galvanic corrosion.

Metal bracket rubber inserts are designed to prevent metal-to-metal contact with the bracket and metal tubing and reduce vibration with its ribbed design.

Automotive NVH Solutions

Fuel Tank NVH

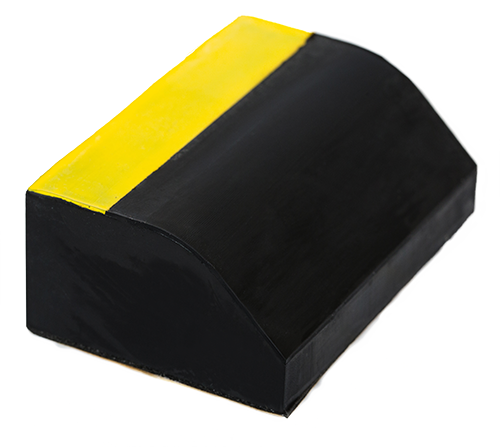

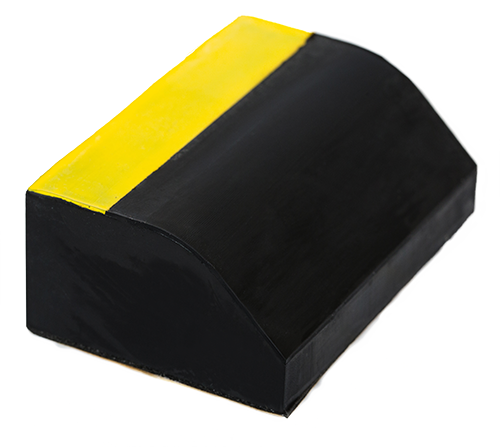

Fuel tanks are large components that can produce a lot of NVH related issues if not engineered well. A common way fuel tank manufacturers combat NVH is by using rubber pads that are positioned between the fuel tank and the cars body.

Fuel system components require complex materials and designs to withstand the harsh conditions they may be put through. When fuel may potentially come in contact with the rubber, it's vital to choose a chemically resistant rubber, like Viton and HNBR.

NVH components are employed within the automotive industry to improve the customer experience by reducing any combination of noise, vibration, and harshness. Custom rubber grommets are used in applications such as isolating coolant lines and HVAC lines, vibration dampers and protecting wiring cables and tubing that pass through panel openings. Below are some examples of where NVH products can be found within a vehicle:

Body and Chassis NVH

Rubber panel plugs are a great way to cover a vehicle's panel openings. The ideal panel plug is a small component that does three major things – it reduces noise transmission into the cabin, it is watertight, and it installs with ease. Rubber panel plugs accomplish all three tasks!

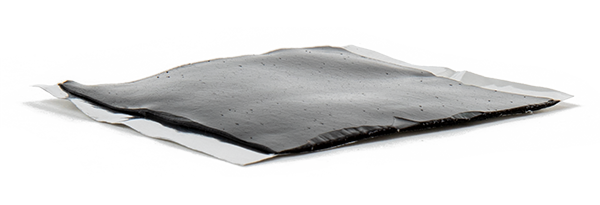

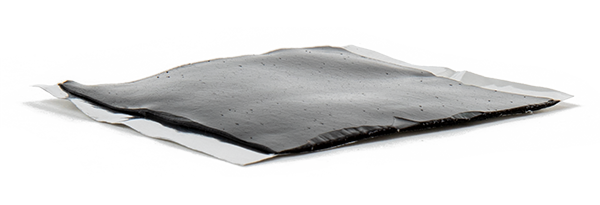

Butyl Patches for panel holes are a very common way for automotive manufacturers to reduce the amount of noise that comes through panel holes. Over the last few years, significant strides have been made towards custom formulations that have improved NVH qualities and improved DFA (Design for Assembly).

Conclusion

NVH within the automotive market has become a vital aspect of manufacturing a consumer-focused vehicle. Car buyers don't want to hear undesirable sounds, and they for sure don't want to deal with the anxiety of components vibrating against each other, resulting in part failure.

Automotive OEMs and tiered suppliers need to take the time to understand what role a part plays in the manufacturing process and product development.