Echo Engineering's Rubber Molding Manufacturing Expertise

- By Echo Engineering

- Dec 12, 2018

Selecting a rubber component manufacturer may seem like a daunting task since there is so much information to consider: which manufacturing processes are used, what materials does the manufacturer work with, what products are offered, what technical expertise is at my disposal, and how good is the customer service? We have answered all of these questions below so you can see why Echo stands out from the competition and is the “go-to” partner for rubber manufacturing!

Echo's Extensive List of Rubber Materials and Processes

When it comes to selecting a manufacturer – the more processes the better! And you will find plenty of rubber manufacturing processes to choose from at Echo.

- Compression Molding

- Injection Molding

- Transfer Molding

- Over Molding

- Extrusion

- Rapid Prototyping

The same is true for rubber materials – the more materials a manufacturer has the better! There is a large selection of common elastomers as well as custom formulations available at Echo. Note the processes and materials listed here are just a sampling of Echo’s offerings – contact us for a more comprehensive list of materials, custom compounds, and processes to meet your specifications.

- Ethylene Propylene (EPDM)

- Silicone (Si, Q, VMQ)

- Fluorosilicone (FVMQ)

- Natural Rubber (NR)

- Chloroprene, Neoprene (CR)

- Polyacrylic (ACM)

- Nitrile (NBR)

- Fluoroelastomer / Viton (FKM)

- Hydrogenated Nitrile (HNBR)

- Epichlorohydrin (ECO)

- Styrene - Butadiene (SBR)

- Butyl

- Sponges / Foams

- Custom Engineered Formulations

- UL Approved Elastomers

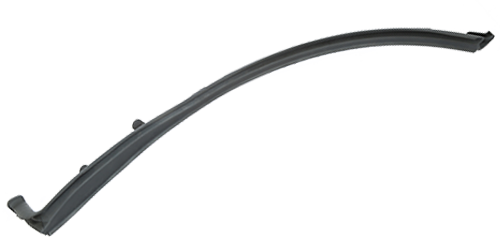

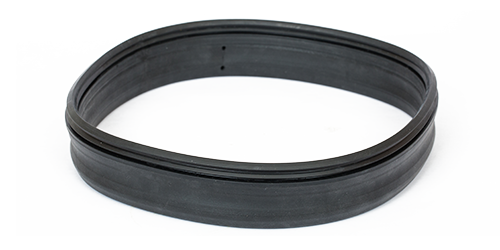

Echo's Diverse Rubber Projects

One of the reasons Echo stands out is we provide stock rubber products as well as custom OEM parts to many industries such as electronics, automotive, agricultural, heavy machinery, lighting, material handling, medical, and appliance. Whether the need is masking, hanging, protection, or OEM rubber components, our engineers will work closely with you to understand the need and your end goal. We can meet your needs with a solution that's efficient and cost-effective.

Echo designs and manufactures complex custom rubber components out of a vast selection of common and custom formulated rubber materials. We have a team of in-house design and materials engineers, 3D rapid prototyping, three-tiered quality management, internal and third-party testing and supply chain management at your disposal. Examples of customer rubber components include:

The Echo Way: Customer Service and Satisfaction

When selecting a rubber manufacturer, it is important to select a partner! Whether you simply want to place a quick order for a stock part, or have a more complex requirement, Echo partners with you to get you exactly what you need. We’ll take the time to understand the role the component plays in your manufacturing process or product development so we can confidently recommend a solution that meets your needs and surpasses your expectations. This level of commitment to customer service and satisfaction is called The Echo Way – and this approach sets Echo apart from the competition!

Additionally, Echo’s team is available to assist you during every stage of the process! Echo works closely with customers, providing strong support in engineering, manufacturing, quality, and logistics to meet customer requirements and expectations. And as previously noted, we have a team of in-house design and materials engineers at your disposal.

But don’t take our word for it - here are what Echo customers have to say:

Quality: “It is real simple, Echo’s products work” – Heavy Equipment Manufacturer

Overall Experience: “If I had to grade Echo based on customer service, delivery, quality and quote response time I would give them an A+ across the board. Their inside team has always been friendly, courteous, helpful and business-like in every manner. Echo is by far one of my top vendors!” - Agricultural Component Supplier

Reliable: “It is critical my parts arrive on time and to print. Echo consistently delivers quality products on time. When expediting parts, Echo exceeds my expectations by going beyond the call of duty to ensure my product is expedited and delivered in a timely manner.” - Global Lighting Company

Technical Expertise: “As a mechanical designer, and a satisfied customer of Echo Engineering, I have worked together with Echo on several major projects involving more than 30 separate components, both simple and complex. I count on them as my “go-to” vendor for molded components.” - Exercise Equipment Manufacturer

Customer Service: “The customer service, and my account manager at Echo have been outstanding. The engineering team has gone above and beyond to resolve issues in the prototype stage to help my company prepare for manufacturing. I would recommend this fantastic team for any rubber or plastic application to everyone.” - Outdoor Recreation

Competitiveness: “Echo Engineering has great customer support. Although Echo is competitive, it isn’t the cost of the product that really matters it’s the cost of the process. Echo has been a good partner offering solutions that reduce the cost of the process.” - Material Handling

Trust: “We've grown to trust Echo with all of our masking needs. We don't even look elsewhere.” – Industrial Powder Coating

About Echo

Since 1966, Echo Engineering and Production Supplies, Inc. has been providing world-class companies with both standard and custom masking, hanging, OEM components and assemblies, as well as protection products. We have an extensive selection of materials available that meet various performance requirements. Our operations include multiple stocking locations, in-house converting, and extensive molding capabilities. These specialized operations – coupled with our team’s design expertise, engineering ingenuity and product development experience – guarantees that you receive fast, innovative, cost-effective solutions that make sense for your business.