Masking Caps and Plugs Popping Out During Curing Process

-

By

Lee Lechner

By

Lee Lechner - Apr 27, 2020

Tornadoes can have speeds of up to 300mph. That’s the same speed your plugs go when they pop out during the baking process! Kidding. It isn’t that fast, but it may look like a tornado went through your curing oven if you’re not using a cap or plug designed to withstand intense internal pressure. Don’t let your oven look like a wasteland. I’ll take you through how you can avoid this type of disaster in the future with a vast selection of awesome engineering and molding designs developed by some of the best masking engineers in the industry.

Why Do Plugs/Caps Pop Out?

When plugging a pipe or some other component that is open on one end and closed on the other, there is no room for air or gas to escape. This causes the internal pressure to build up during high-temperature baking, ultimately resulting in the dreaded POP (your plug popping out).

Tapered plugs are the biggest culprit for popouts. Why? Well, it comes down to the amount of surface that the tapered design grips onto. Unlike a pull plug where most of the plug is 'grabbing' onto the surface keeping it firmly in place, the tapered plug design only allows for a fraction of the plug to grip to the surface. This means that it's much easier for the plug to pop-out once pressure builds.

The Science Behind Pressure

When gases, liquids, and solids are heated, they expand. When the gas is heated in a closed container (like an air reservoir tank), the particles collide with the sides of the container, resulting in pressure. The greater the number of collisions, the greater the pressure buildup becomes.

Preventing Cap and Plug Blowouts

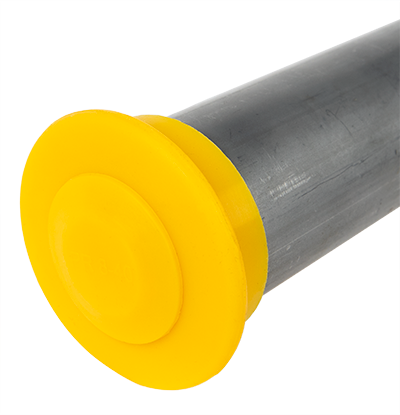

Standard Vented Plugs

During the curing process, the vent in the plug allows internal pressure caused by high heat to escape. It does this by having a small slit (the vent) that opens when pressure builds up and gases push outward. This means no more plugs popping out.

During the coating process, external pressure, like your powder paint or e-coat, pushes on the plug. But won’t paint or dirt go through the vent as well? Nope. There is extra buildup material placed around the slit on one side that comes together as pressure pushes on it. This results in the slit closing even tighter, protecting your part from paint and debris. The slit only opens when pressure pushes gases outward during the baking process.

Cross-Vent Plugs

Putting your parts through a shotblast application? Yeah, we've seen it before. We've literally had customers pour out blast media to show how bad standard vented plugs perform during blasting.

Because they weren't designed for that, we developed a new breed of vented plugs. We typically just refer to it as the "cross-vent plugs". There is still a vent integrated into the design, but the difference is that there is a top section with a cross-vent area that protects the inside vent but also allows pressure to escape during the curing process.

Pop-Pin Vents

Pop-pin caps and plugs are an excellent way of keeping coating out while releasing pressure buildup. Customers use these types of caps and plugs during tricky processes, like E-Coat.

The way they work is when pressure increases, the central 'pin' releases the air. During this time, the air being released prevent liquids from entering the part being coated or washed. Once the pressure is low enough, the pin returns to its original setup and seals out pretreatment and paint.

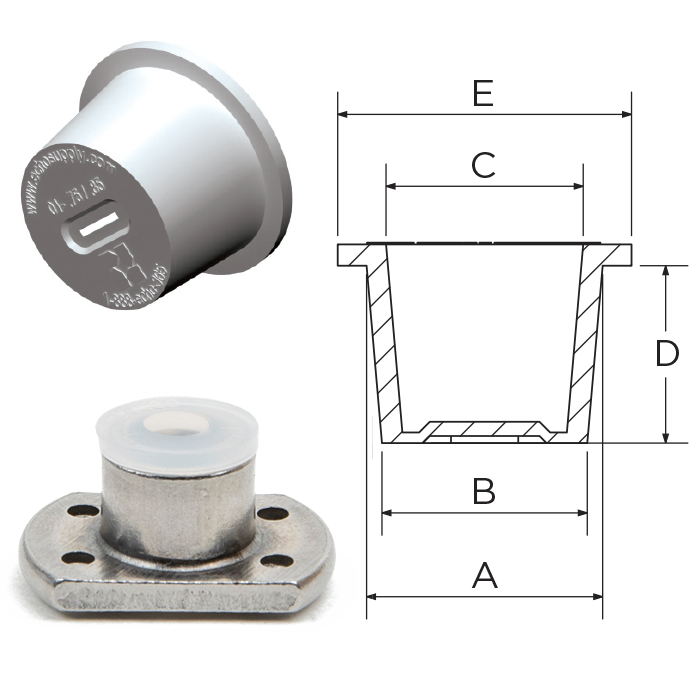

Internal Barbed Vents

These are meant specifically for cap applications during powder coating processes. The spline vent feature gives the ability to release pressure during the entire process.

These types of caps require a solid foundation of engineering design and tooling design to manufacture effectively.

Over-Molded Threaded Plugs

If the surface you're masking off is having issues with plugs blowing out and it involves a threaded hole, you can't go wrong with an over-molded threaded plug.

This is a great option as it would take an immense amount of pressure for these to blow out. You're also able to tighten the plug as needed, so ensure you have an effective seal.

The drawbacks of this option will be the amount of time needed to install and remove them. They will also be slightly more expensive than the other all silicone options due to the addition of a metal bolt.

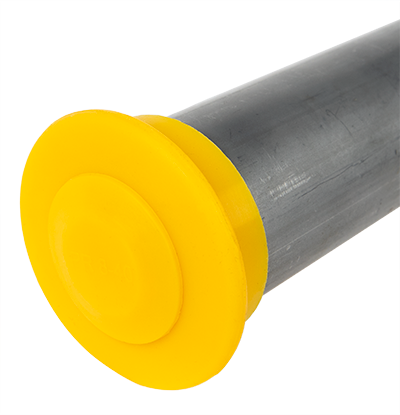

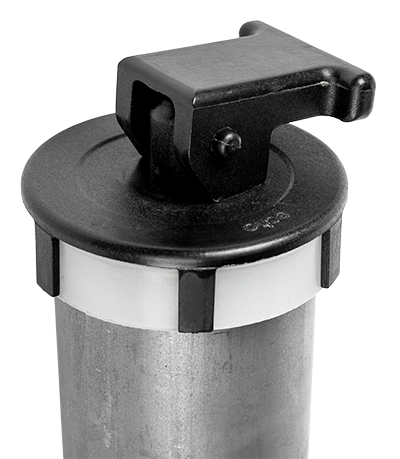

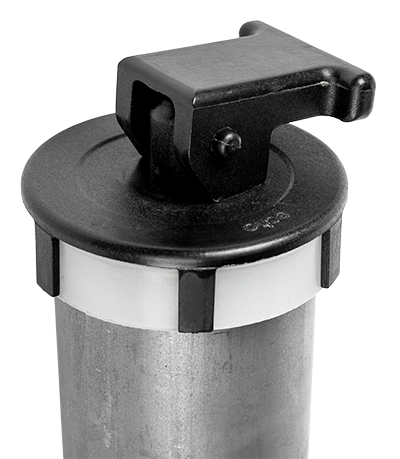

Expandable Caps

These are some of the more highly engineered masks that powder coaters and e-coaters will come across. Expand caps/plugs combine high-temp resistant plastic with silicone rubber in a way that expands when the handle is pulled down in order to seal the metal from having any e-coat leak in, while also preventing it from popping off.

While this does make them a more expensive option, it's more than worth the price due to the cost savings from minimal installation and removal times and a decrease in rejection rate.

Quick Fix Solution for Caps

If you're having issues with your standard silicone caps popping off during powder coating, one quick solution that we've seen work is making a very small slit or poking a hole in the top of the cap. This will allow pressure to escape, preventing potential cap blowouts.

Won't this result in powder getting in?

If you poke a large hole, then yes. But, the nice part about using rubber is that a thin enough hole will result in the rubber still closing upon itself while you apply powder to your part, while also giving it the ability to release pressure as it goes through the baking process.

In Conclusion

This post was developed to show you that caps and plugs do pop out, so you're definitely not alone. Luckily, there are catalog options you can try out today, like the vented plugs, but for larger-scale coaters, you have plenty of different designs you can explore using. Each has its pros and cons.