The Future of Noise Reduction Inside Electric Vehicles

-

- Apr 30, 2020

With the rise of all-electric vehicle manufacturers, like Tesla & Rivian, along with longtime, well-known OEMs like Volkswagon and GM making the switch to EVs, a new trend has become more prevalent. That is, without the sound of an internal combustion engine generating ample amount of noise, consumers are now complaining about the other sounds being produced by the road, mechanical components, and basically, anything loud making its way into the vehicle's cabin.

Currently, EVs carry a decent price tag when purchased brand new. With that comes the expectation of a luxurious ride. As self-driving cars become increasingly accepted and used by the public, time spent during a commute will begin to shift towards other tasks, such as conference calls, reading, and catching up on last night's emails. So, let's look at the cabin of the vehicle as your own office...

Loud noises have become one of the greatest irritants in an office environment. One study showed that 99% of employees reported that their concentration was impaired by various types of office noise, like telephones ringing and people talking in the background. Researchers also found no evidence that people become used to these sounds over time. Now imagine all the noises thrown at you while on your commute and how hard it's going to be to concentrate if EV manufacturers put a high amount of attention to reducing the amount of sound entering the vehicle's cabin.

We crave the uninterrupted focus spikes where we aren't distracted by constant sounds and annoying noise pollution. We especially don't want to hear constant squeaks and rattles from all the little mechanical devices found throughout the vehicle.

Noise-Cancellation Technology

If you've never experienced noise-cancellation headphones, you should definitely at some point go to your local electronics store to try them out sometime. They're an amazing technology that has grown immensely in popularity over the years.

With that said, it was only a matter of time before noise-cancellation technology would be introduced to the automotive industry. And what better time now that EVs have introduced us to more unwanted sound due to lack of an internal combustion engine to drown out the noises.

How Noise-Cancellation Works

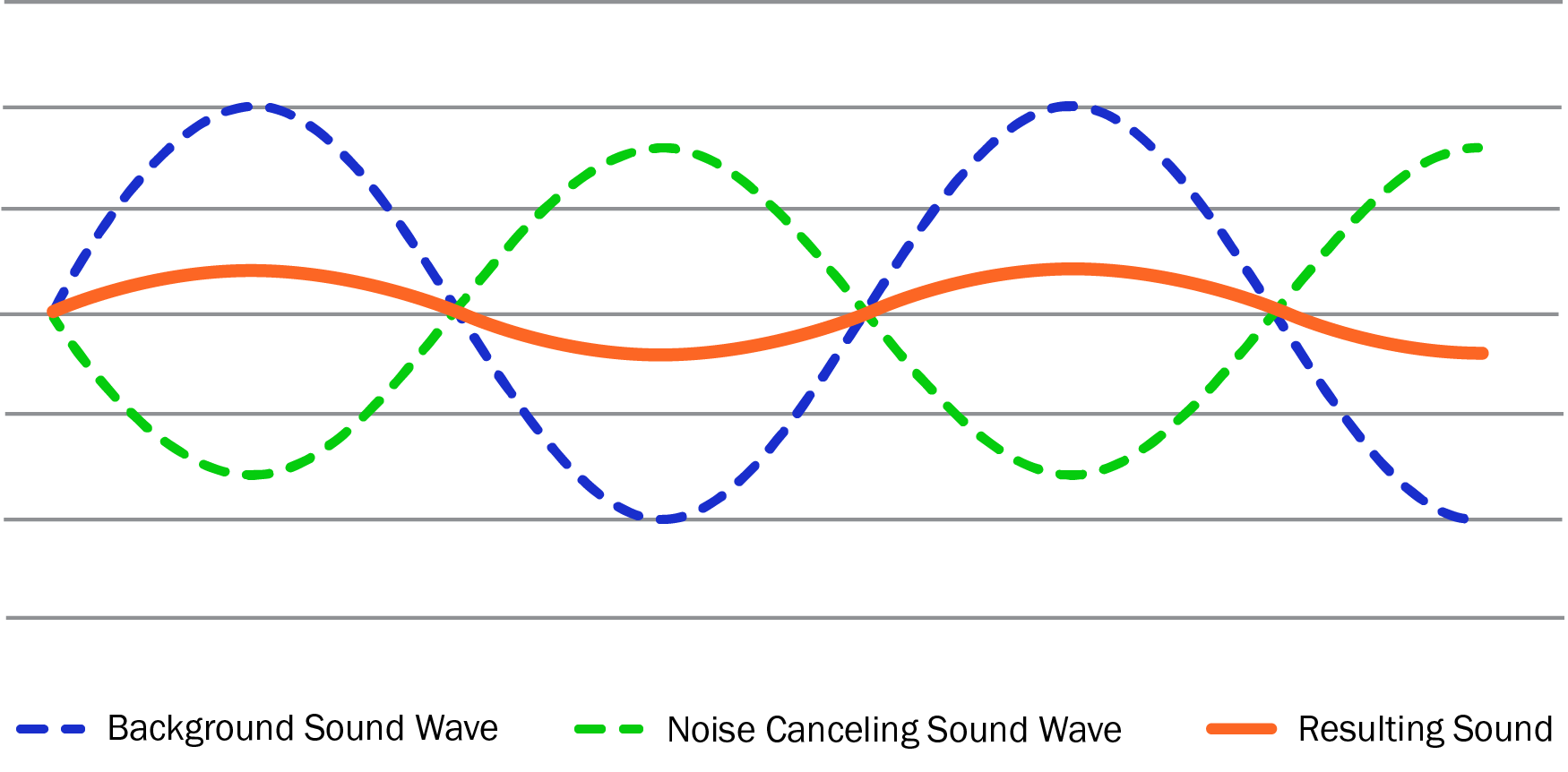

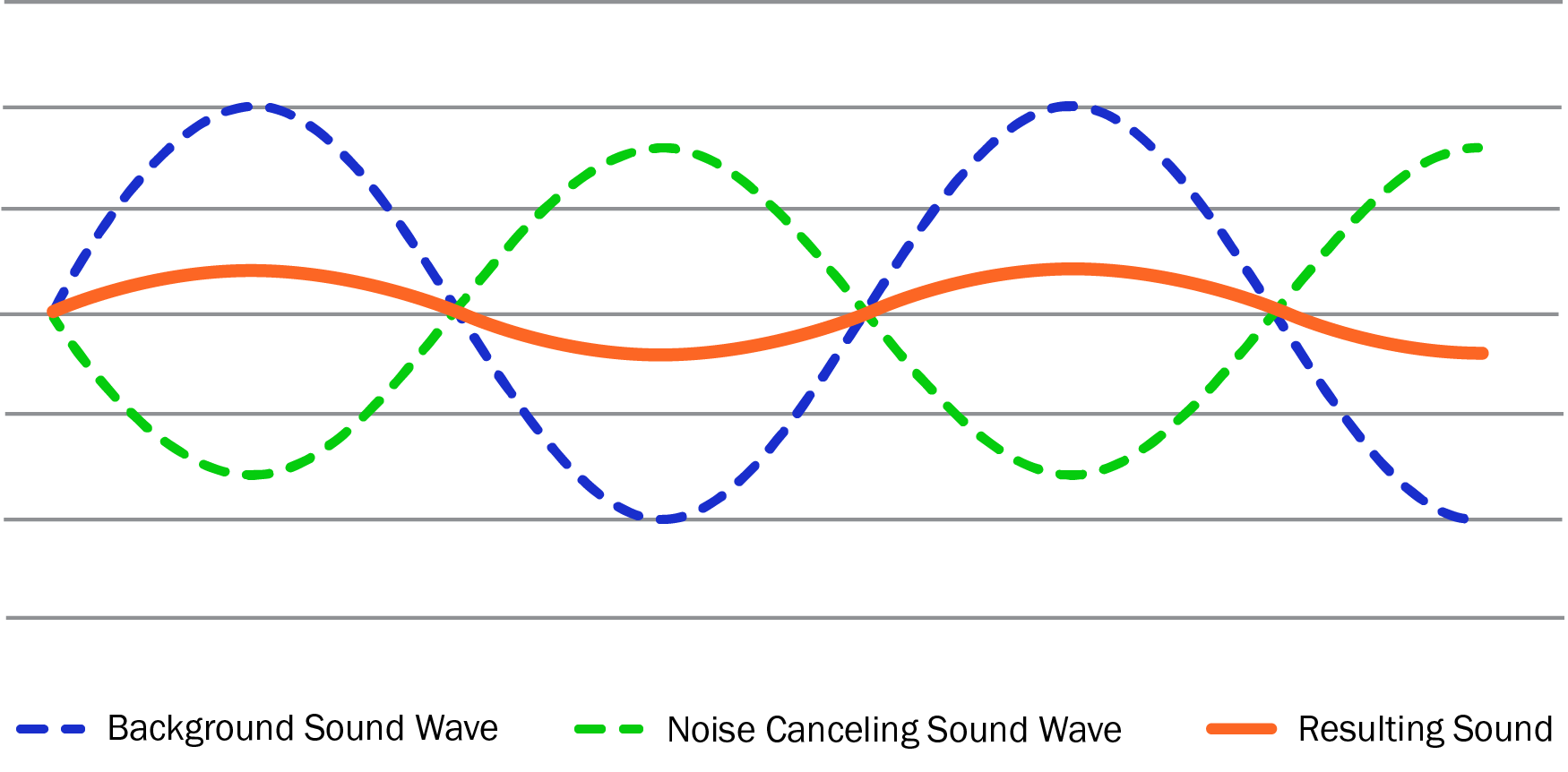

Noise-cancellation technology works by listening to the sound around the vehicle. The technology analyzes the sound waves being produced. Sound waves are made up of peaks and valleys. When noise-cancellation technology detects sound waves, the tech creates a new waveform that is the total opposite of that sound.

So, for every valley (in the sound wave), the noise-cancellation technology creates a peak. And for every peak, it creates a valley. This results in the sound waves canceling each other out. (See the graphic below to see what this looks like)

Companies like Bose have started introducing noise-cancellation technology in automotive applications. Their QuietComfort Road Noise Control is an algorithm that uses the vehicle sound system to actively reduce noise from the road, as well as the vibration from tires & suspension.

Accelerometers mounted on the vehicle body enable their algorithm to continuously measure vibrations that create noise. This information is then used to calculate an acoustic cancellation signal, which is delivered through the vehicle’s speakers to reduce the targeted noise. Microphones placed inside the cabin monitor residual noise levels, allowing the system to adapt the control signal for optimized performance over different road surfaces, while automatically adjusting over time as the vehicle ages.

All QuietComfort Road Noise Control details provided by Bose - For more info, click here

Noise-cancellation works best with canceling out consistent noise. This is because matching a sound wave is extremely difficult as you are only able to eliminate so many sounds at once.

Noise-Cancellation in Vehicles

Noise Damping Mats and Patches

To achieve a silent ride, you need a way of damping the sound from entering the cabin. But, before we get into that, we need to have a better understanding of what exactly does sound damping mean.

What is Sound Damping?

Noise damping is a way of preventing vibrations on vehicle bodies and materials by converting the vibrations into heat. It works by reducing energy stored in an oscillation. The goal is to slow down an oscillatory system as fast as possible by adding noise damping materials into the system. Reduction of the duration and size of vibration a vehicle experiences will result in a reduction in noise.

Noise Damping in Electric Vehicles

A popular product EV manufacturers have taken advantage of due to its great ability to dampen sound has been noise-damping mats & patch, sometimes also referred to as butyl foil mats.

Sound damping mats are lightweight, typically made with butyl rubber & aluminum foil, and conforms well to sheet metal and other hard substrates. The butyl rubber has excellent vibration-damping characteristics and is complimented with the use of an aluminum backing.

Using a thicker aluminum foil, they're able to achieve improved vibration damping and better heat control, as aluminum is excellent at dissipating heat fast. The added benefit here comes from helping reduce the amount of heat coming battery from entering the cabin.

Below is a simple demonstration of how it works to dampen the vibration and sound of a metal object.

What you can expect to see in future EVs in an increase in the overall usage of noise-damping mats for paneling and patches for panel holes. As well as an increase in the thickness of the butyl for improved damping performance.

Butyl Mat Acoustic Properties: Using the theoretical maximum loss factor is 1 (no vibration). An undamped 1mm thick steel panel has a loss factor of roughly 0.001 at 200 Hz. When a butyl mat/patch is applied to that panel, it increases the loss factor to 0.17 (performance varies depending on the temperature).

More Sound Reduction Methods To Keep an Eye On

Above we listed just a couple of ways in which EV manufacturers are combating noise from entering the cabin. But that's just the tip of the iceberg for this topic. Here are few products being used already that have made a significant impact on in-cabin noise reduction.

EPDM Panel Plugs Replacing TPE

We've discussed this before in previous posts, but it's vital to stress the importance of this shift. These types of plugs were not something considered by traditional vehicles due to a slightly higher price. TPE panel plugs were mainly for visual aesthetics and to keep out debris.

EV OEMs started the shift towards EPDM panel plugs due to their great sealing ability and ability to block sound from entering the cabin.

Sound Insulation Foam

Sound insulation foam is used for several reasons. It's an excellent replacement to a vehicle's carpet padding. An open-cell bottom half makes a great method of absorbing sound and also great insulator from the heat that makes its way through noise-damping mats. A close-cell foam top half makes a great way of sealing out liquids from penetrating deep in the vehicle's interior.

Another benefit includes its ability to absorb the noise be produced inside of the vehicle. Imagine being on an important call and the person you're speaking to starts complaining about how loud the background is and the echos they can hear. Insulation foam works just like you'd imagine seeing in a recording studio to give a better acoustical performance.

Tire Tread Design

Engineers behind tire tread designs continue to work towards developing a way of modifying the audible noise that a tire generates in order to get one step closer towards generating a more pleasant 'white-noise'. Using pitch sequencing, engineers tinker with the different tread pitches and placements by aligning lateral grooves with adjacent tread blocks. But will this be all that we see in the coming years or will there be a drastic change, such as the airless tires that are gaining momentum in adoption? As technology continues to evolve, so will the results.

Advancements in Asphalt Pavement

Time to start thinking about noise reduction outside of the car. Studies continue to be put in place on reducing the sound coming from busy highway systems and one method has been implementing recycled tires that are mixed into the asphalt. This is also referred to as rubberized asphalt. Noise tests on rubberized asphalt have shown a 50%-90% reduction in noise. This is huge! But this is just one way of reducing pavement noise. For example, researchers at the University of Notre Dame created a new method of grooving pavement to reduce highway noise even further. Check out their work here.

Future of Mobility

The increase in worldwide demand for electric vehicles has brought about unique opportunities for in-cabin improvements. The future potential of these vehicles will become even more abundant as we begin the shift towards self-driving cars.

Be sure to subscribe for future content and let us know what you'd like us to cover in the future.