Best Masking Plugs For Powder Coating

-

By

Lee Lechner

By

Lee Lechner - Jul 13, 2020

It can be a pain to keep paint from getting into threaded or non-threaded holes. It's even worse when your customer gives you strict quality restrictions. Often, some sort of rubber plug will be required to successfully and repeatably mask a hole.

An element of powder coating that plays a role in your masking selection is the temperature at which you're running your curing oven. Because of the high temperature, powder coaters will typically use silicone as the material of choice for their masking plugs due to its 600°F temperature resistance.

This post will take you through your top options for masking plugs during powder coating and why you'd select one option over the other.

Best Powder Coating Masking Plugs

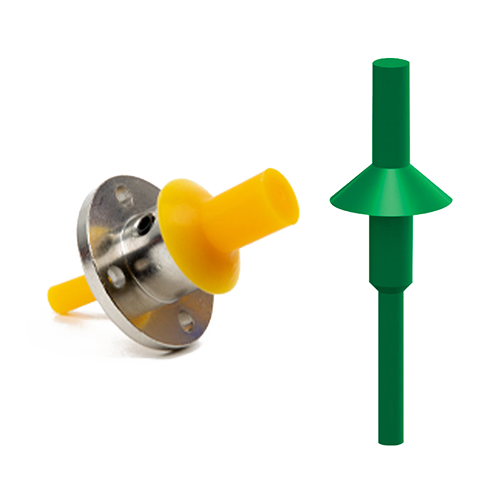

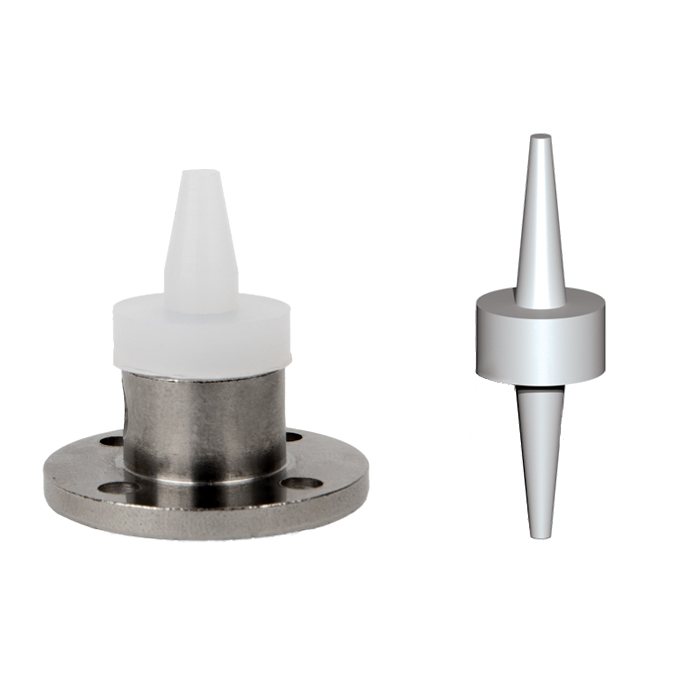

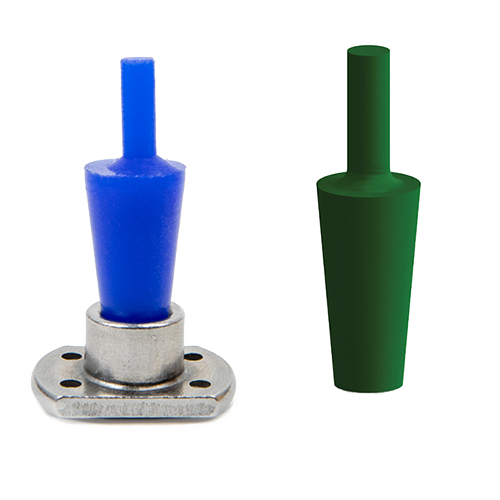

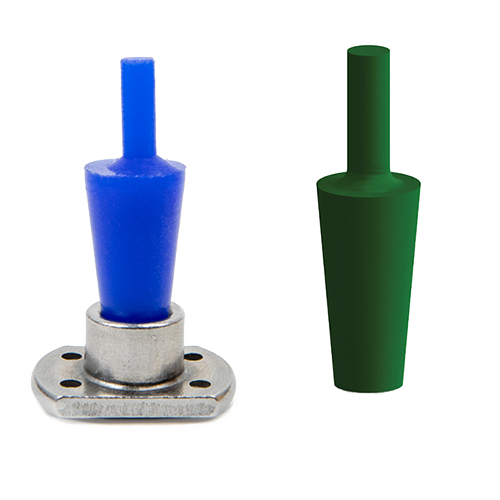

Silicone Tapered Plugs

Silicone tapered plugs are hands down the most popular type of plugs you'll see in a powder coating shop. They're widely used as due to their tapered design giving them the ability to be firmly pressed in for a tight seal into blind holes, as well as giving them the ability to fit multiple hole sizes.

They're also made with silicone, giving them the ability to be reused several times before having to dispose of them. If you're unsure what plug to use, check out our new Hole Size to Mask dropdown filter to help you pick the best tapered plug for the hole you're masking.

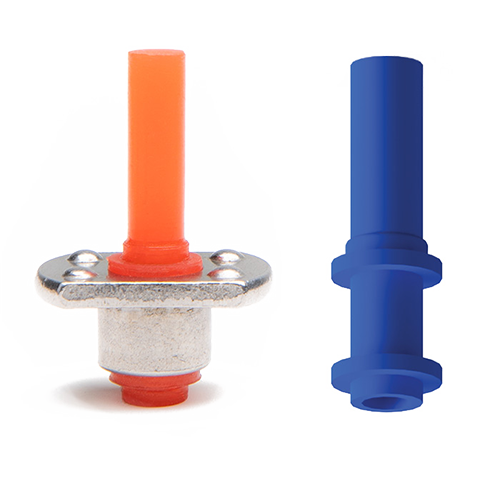

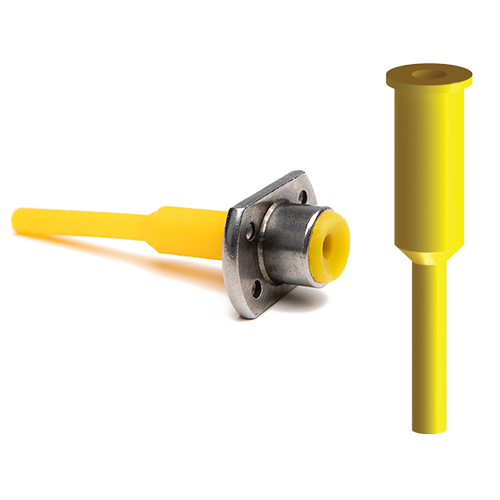

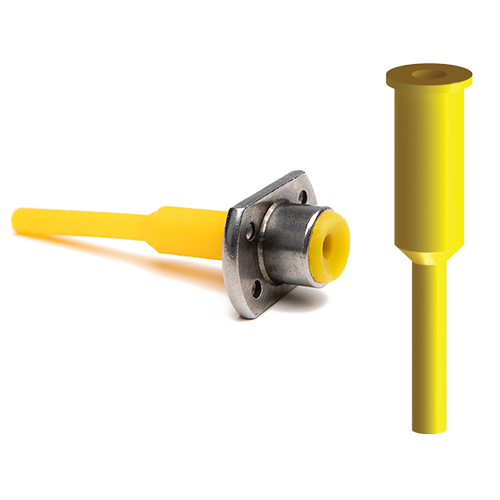

Silicone Pull Plugs

While tapered plugs are fantastic for blind holes, silicone pull plugs are just as great for through holes. Pull plugs feature a larger handle, making them easier for installation and removal. These pull plugs are great when your main task is masking the bore threads if you need to mask the leading three or chamfer, or if you are concerned about shadowing, check out the chamfer pull plug below.

When ordering these, you'll want to get a plug that is slightly larger than the inside diameter of the hole you're masking.

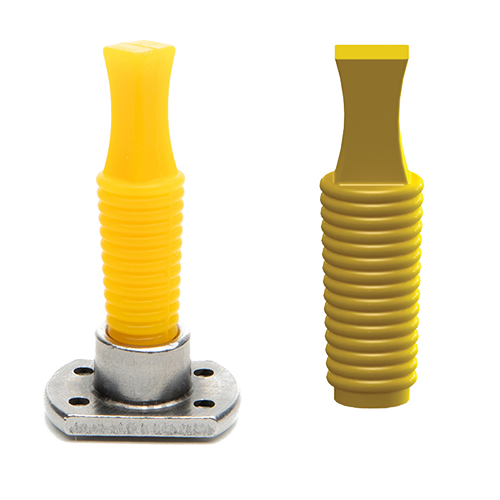

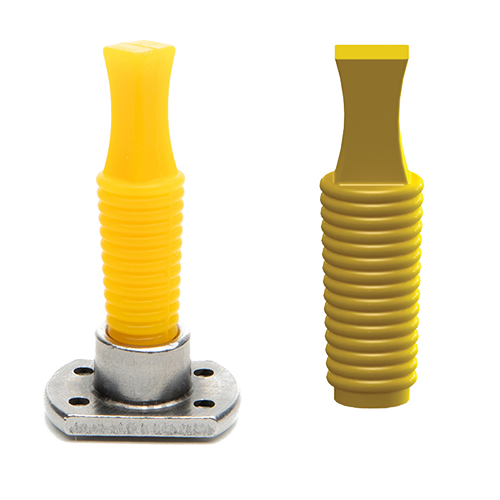

Silicone Flangeless Plugs

Flangeless plugs feature a ribbed design, making them an excellent option for threaded holes as they'll grip onto the threads to ensure a tight seal. They also help with reducing the chances of your plugs popping out when masking blind holes.

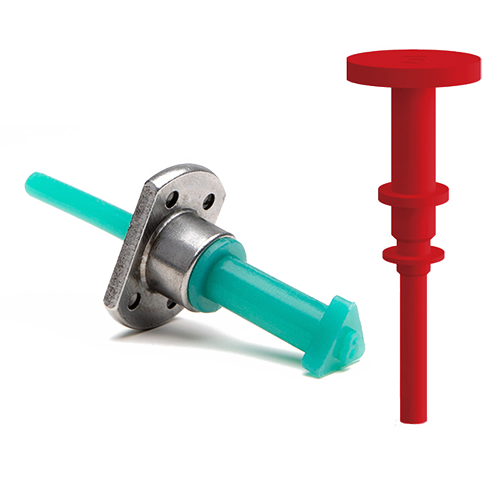

Silicone Chamfer Pull Plugs

The chamer pull plug is a great option for through holes, especially when you need to mask off leading threads and chamfers. They're also made with a softer rubber, giving a little beter sealing capability. They're a top option for masking off weld-nuts.

Silicone Thread Plugs

I'm personally a big fan of these plugs as they're super easy to install and they mask off the leading thread of a blind hole. Their compact size also provides you with less interference when you're applying powder, which will help with reducing any shadowing effect.

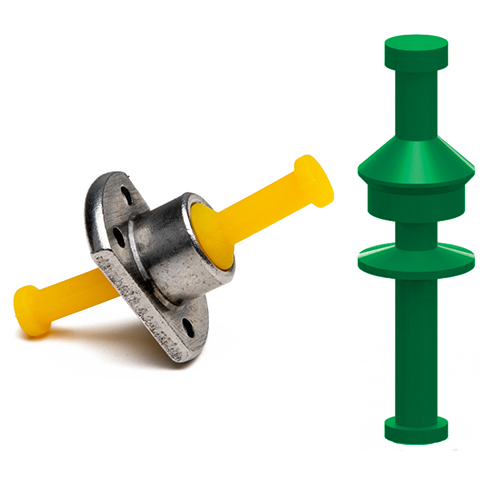

Silicone Tapered Plugs with Handles

These are an excellent alternative to standard tapered plugs as removal is easier because of the added handle. The drawback to this style though is that there are a limited number of sizes (compared to standard tapered plugs). That said, the slight taper means they can be easily installed across several hole/thread sizes. They are color-coded and cover holes from 1/8" up to 5/8"

Best Plugs for Masking Weld Nuts

Best Plugs For Masking Off Grounding Areas

Conclusion

Masking plugs come in various designs due to the variety of different applications they may be needed for. Silicone plugs were developed to help give powder coaters an effective seal and improve their finishing line's ergonomics.

If you're still unsure what would work best for what you need, reach out to us today and we'll recommend what you could try and even send you some samples to try before you buy.

About Echo Engineering

Echo Engineering has been the go-to industrial masking expert for powder coaters for over 50 years now. We were founded in a garage in Silicone Valley making die-cuts for printed circuit board manufacturers and then transitioned to catalog and custom molded masking solutions as our customer's needs grew over time.

We take pride in our powder coating engineering expertise we've developed over the years, the R&D we've invested in, and our new propriety rapid silicone prototyping we recently developed to speed up the manufacturing process. Our engineers are some of the best in the business, so if you have a complex masking issue, chances are we can help.