Future of Electric Vehicles: Sustainable Plastics

-

By

Lee Lechner

By

Lee Lechner - Nov 10, 2021

Future of Electric Vehicles: Sustainable Plastics

One of the many reasons why electric vehicles were developed is because they are an ideal alternative to fossil fuel burning combustion options, giving them the ability to reduce/eliminate carbon dioxide emissions. But, as with many big impact claims, there are now people taking a closer look into just about everything that goes into manufacturing a vehicle. What if eliminating the usage of fossil fuels was just the tip of the iceberg?

In this post, we are actually going to cover two forms of sustainable plastics that automotive manufacturers are using or should be highly considering over the course of the next few years: Plastics used on the finished vehicle and plastics used for shipment protection.

Automotive OEM's Sustanability Initiatives

Big initiatives like sustainability typically come from OEMs. They're the ones that have to take the initiative and make the decision to change. In this case, its been pretty unanimous as you'll see nearly all of them have put in place future sustainability goals, including:

Nissan: On top of multiple recycling initiatives in-house and at their suppliers, Nissan's goal is to use 30% of material alternatives that are not dependent on newly-extracted resources by 2022

Ford: Goal of using 20% sustainable material by 2025

GM: Goal of at least 50% sustainable material content in their vehicles (measured by total weight) by 2030

What is a Sustainable Plastic?

When something is sustainable, it essentially means your'e able to meet your current needs without compromising future generations' abilitiy to meet their needs. In order to to meet the needs of sustainability in plastics, manufacturers are using two different methods: Injection molding with recycled plastics and using biodegradable plastics to replace traditional plastics.

Injection Molding with Recycled Raw Material

The focus for most of what we see with using recycled materials in automotive is to find a way to achieve consistency through all the parts molded and, most importantly, being able to match physical property requirements OEMs demand from non-recycled injection molded parts.

The primary method of meeting those needs is by mixing recycled materials with virgin materials to offset properties that were lost during recycling. With that said, understanding the source of plastic is highly important, as plastics can actually carry chemicals that they absorbed from their original use, and introduce those chemicals into the new product they're molded into and even damage the mold.

Biggest Pros of Injection Molding with Recycled Plastics

- Sustainability Initiatives: The main objective here is sustainability. Not only is this a better option for the environment, but it may also give you more growth opportunities with your customer base.

- Pricing: From a material cost perspective, recycled plastic material will be a lower price

Biggest Cons of Injection Molding with Recycled Plastics

- Material inconsistency: By adding recycled polymer pellets to your batch, you may end up with inconsistent batches that result in part variations and quality issues, such as random shrinkage from different batches.

- Ability to obtain/meet physical properties that you'd find with traditional polymers: In the automotive world, this one is critical for some components. You'll need to work closely with the injection molder and material supplier to get this right.

Injection Molding with Bio-Based Materials

The nice thing about bio-based plastics is that they're compatible with existing molding equipment, but injections molders will still need to test and experiment with the materials to iron out all the technical elements required for molding parts that meet spec. Just like standard plastics, biodegradable plastics can be modified by blending with other materials in order to achieve the specific physical properties you're needing.

The unfortunate side of biodegradable plastics that have held it back from being more widely used is that price of the material used is typically a little higher than standard polymers, such as LDPE.

What is Biodegradable Plastic?

Biodegradable plastics are typically going to be made from plants (such as bamboo or sugarcane) rather than fossil fuel and can be decomposed without ecological harm into water, carbon dioxide, and biomass. Most biodegradable plastics are called "bioplastics".

So, how long does it take to decompose? This is going to mainly be dependent on many factors, including where they end up. If they're placed in a microbe-rich environment, bioplastics can take anywhere from a few months to a few years. Compare that to traditional plastic components that take hundreds of years to fully decompose!

Applications

When you search biodegradable plastics, you'll typically see that it's used for food service containers, cutlery, and other disposable items. But what about automotive? We discussed how OEMs, like GM, are measuring sustainability by vehicle's overall weight, but what about sustainable plastics that aren't on the end vehicle?

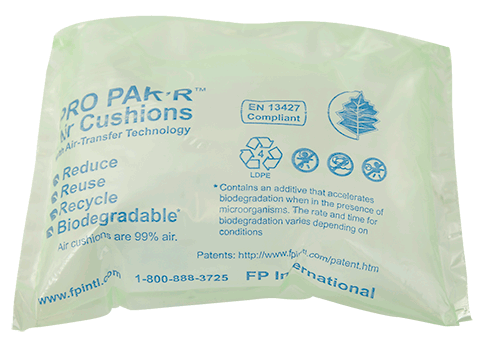

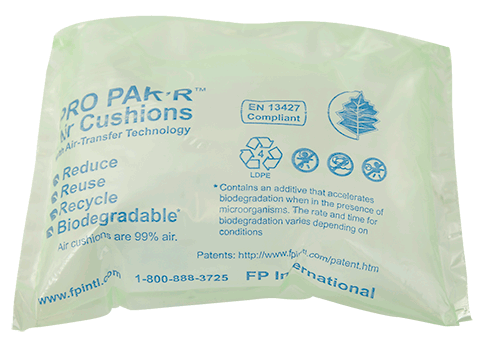

This is where biodegradable protective plastics come into play. In the automotive world, quality is critical. An area where OEMs are pushing their suppliers to work on is the supplies used to protect surfaces and critical components during shipment and storage.

Air Cushions in Shipments: This can be something as small as the air cushions (like what is shown in the picture here) used to ship products, like masking tapes.

Critical Component Caps/Plugs: An area that has a ton of potential is the caps and plugs used to seal and protect fluid routing lines (Brake lines, A/C Lines, etc.), sensors, and critical threads that may be exposed until final installation.

Conclusion

With the impact manufacturing is having from a global perspective, it is definitely time to put sustainability as a high priority across the board. Are we able to reuse/recycle plastics the same way we're able to reuse/recycle metals and papers? Not quite. But recent advancements and pressure from OEMs will lead us towards a more sustainable future.

At the absolute very least, we suggest you experiment with different materials. It's going to be worth it not just from a capability and marketability perspective, but also from knowing that what you did made an impact. If you're interested in exploring sustainable plastics, contact us below to see what we can do together.