Automotive Plastic Fasteners: Fir Tree Design Basics

-

By

Lee Lechner

By

Lee Lechner - Mar 29, 2023

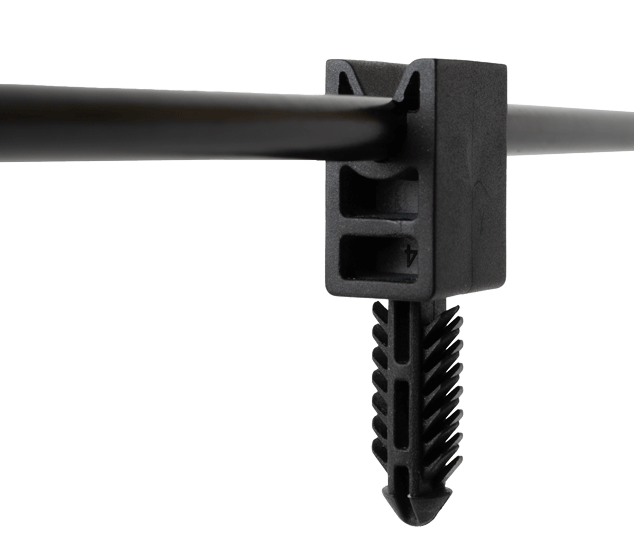

The fir tree design (also called the x-mas tree design) on fasteners and clips is a solid design capable of high removal forces to ensure it remains in place. It is most commonly found on many off-the-shelf push panel fasteners that are widely available from various sources. But what about when you need more of a custom solution for your application?

In this post, we will take you through the pros of using fir-tree features, some commonly used designs, and a few technical elements you should know.

Pros of Fir Tree Fasteners

There are several reasons why fir tree fastening designs are more commonly used today. Here is a list of some of the top reasons:

- Fast Installation: Installation is as simple as pushing the fastener in with fir tree designs, resulting in a quicker takt time on your production line.

- No Additional Tools: No additional installation tools are required, such as a screwdriver or wrench, as this feature is designed to be pushed in.

- Part Consolidation: Fir-tree feature is integrated into the part's design rather than you needing an additional screw or nut/bolt to fasten to the vehicle's body.

- Ergonomics: Repetitive motion of turning a bolt vs. simple push installation (or using a screw gun). When done correctly, they minimize repeated stress on operators.

- Wide Panel Thickness Range: Relative to some other plastic fasteners, a fir tree design is versatile and can accommodate a wide range of panel thicknesses depending on the length of the fir tree – this means the same fastener can be used in multiple applications.

Fir Tree Fin Styles:

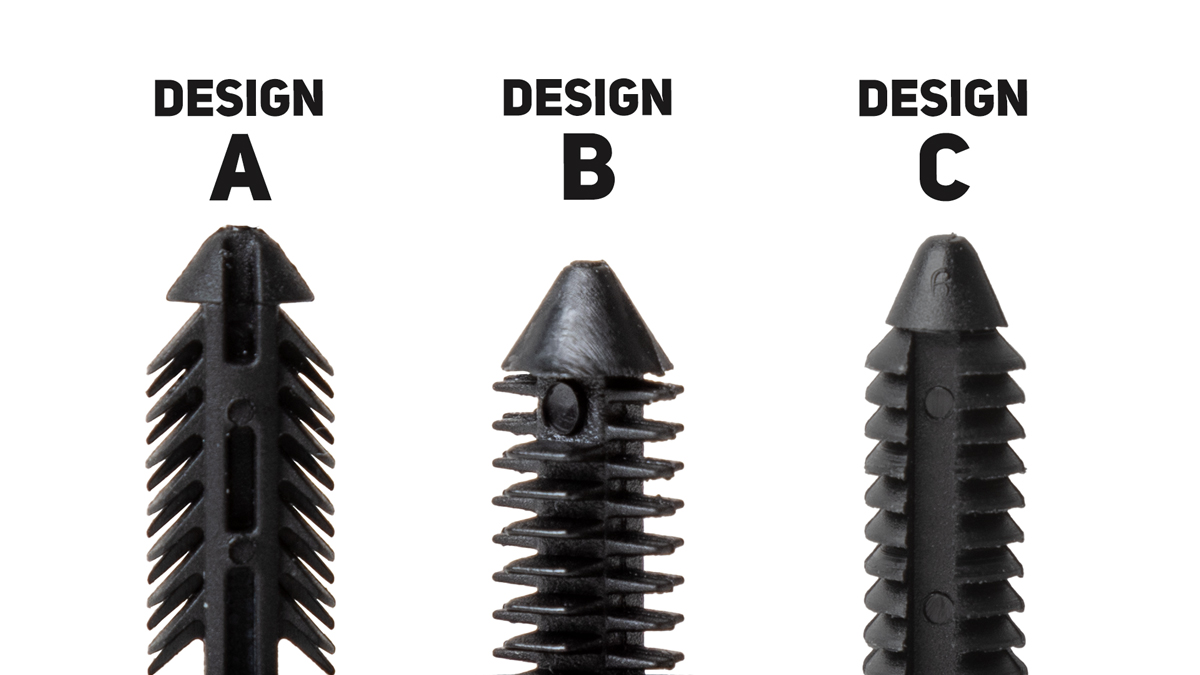

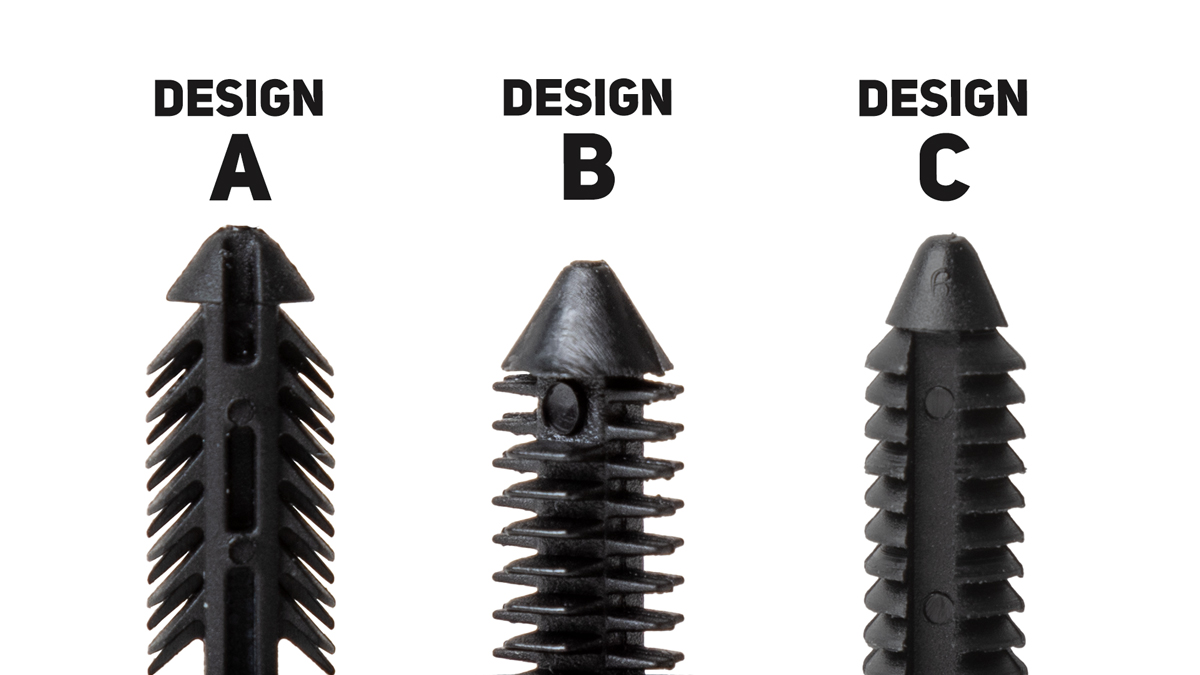

When it comes to the fir tree designs, there are three primary (but not limited to) styles you'll typically choose from that are shown below.

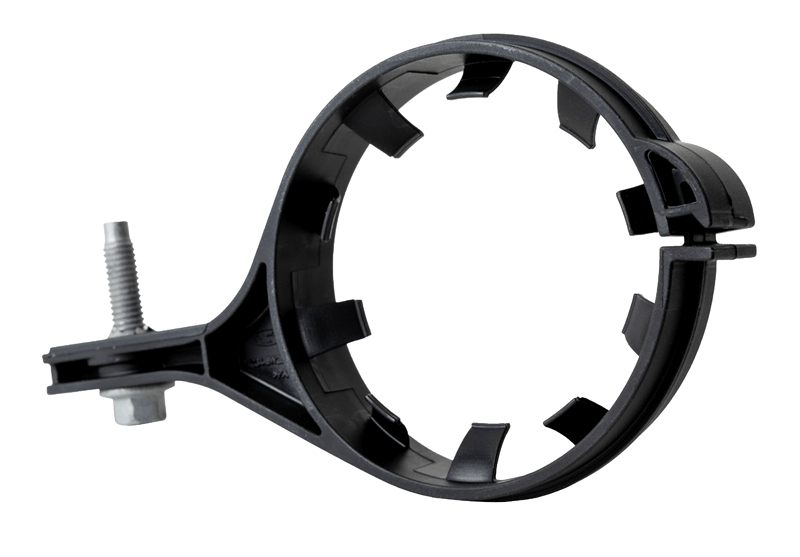

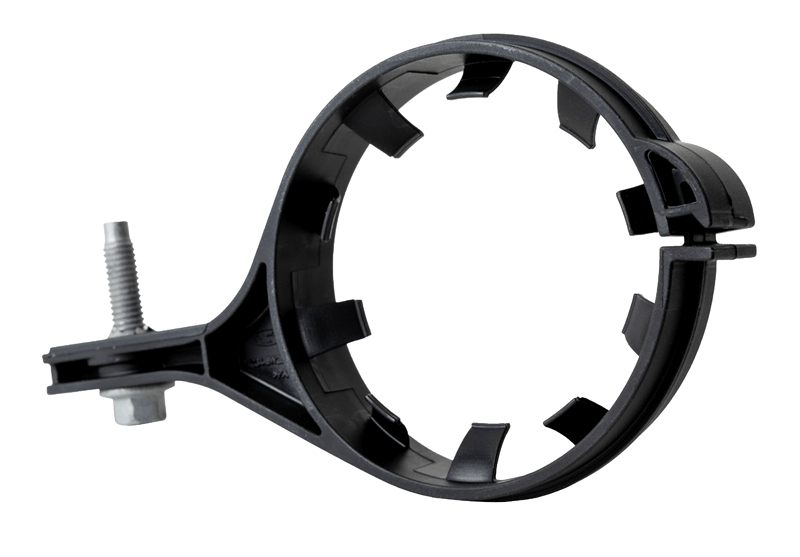

Design A - Angled Fins: This option is characterized by the angled fins that can be flat or offset, with its strength being ease of Installation and high retention force. Because the fins are angled, they don't have to flex as much during Installation, but when they spring back, it's extremely difficult to remove as they would have to bend entirely back, likely resulting in breakage. This makes it an excellent option for automotive applications such as fluid routing tube clips and wire harness clips, where it is crucial the clip stays in place and does not fall out when the vehicle is in motion.

When comparing flat-angled vs. offset-angled fins, flat will typically be preferred. Offset angled fins tend to flash, or the EDM electrodes don't burn in the tiny features, so you may get varying geometry on the fins, making the design likely to be more inconsistent. Offset also tends to have a higher insertion force because they interfere with each other when being installed, which is especially problematic on thicker panels.

Design B - Straightout Fins: This style is commonly used in various off-the-shelf automotive interior fasteners. They are a balance of ease of Installation and ease of removal when needed. You'll likely not see this design being used for applications that require high retention force, such as brake line / fluid routing clips.

Design C - Curved Fins: This option is similar to Style A but with curved fins rather than the pointed ones used in design A. Like Design A, this option is designed to deflect inward for an easier installation and flex back out to lock it in, making it very difficult to remove. When inserting this type of fir tree into a circular hole, you will have more contact between the fin-retaining surface and the panel, increasing the clip's retention.

An issue with this design can sometimes be that they're slightly harder to tool up and mold than the other designs, meaning the tools are more expensive. During processing, you also have to pull all the undercuts created by the "fin" area, which means you need a flexible material and ensure that the undercut is not too deep/fin too long. So, knowing which material you can use and how deep the undercuts can be is a crucial consideration.

That said, when designed properly, design C is often preferred for its consistency in performance.

Fin Style Design and Its Impact on Insertion and Retention Forces

With the ribs, the size, angle, and spacing will play a significant role in the insertion and retention force. The intricate features of the tree design require special attention to the spacing between the fins and areas where there may need more material vs. regions with too much material.

Other factors that impact insertion and removal force include hole size diameter, panel thickness, moisture (nylon is hygroscopic), and the fastener's material.

Fir Tree Insertion Point Designs:

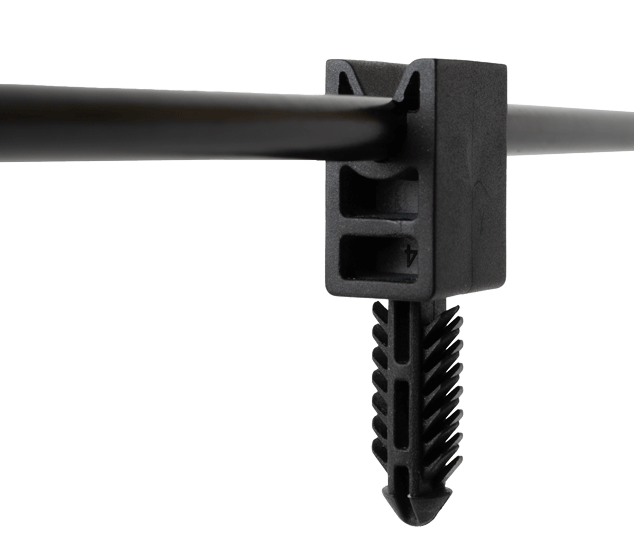

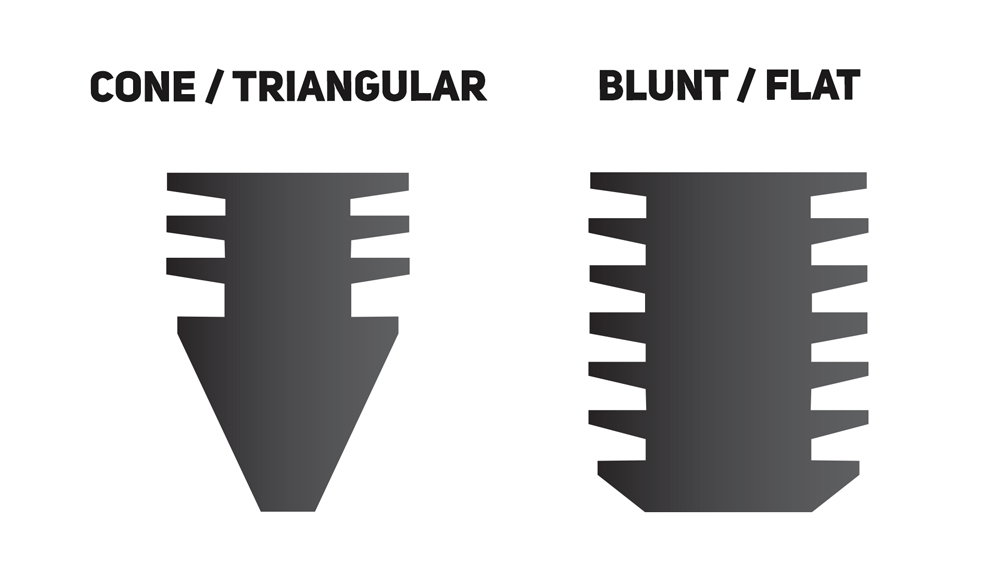

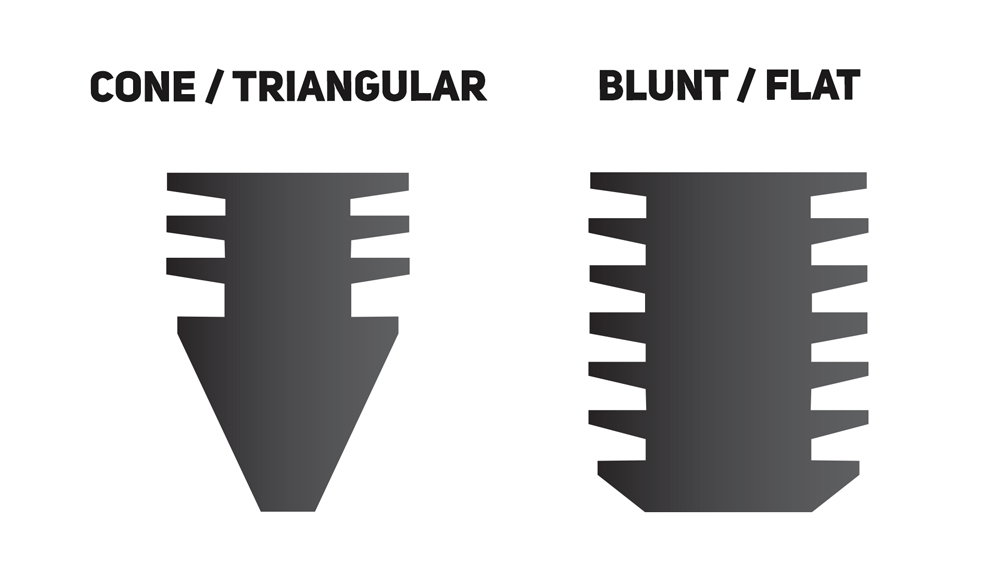

A perk to going with fir-tree designs is making the installation process more manageable. Another element that can impact its ease of use is simply looking at the type of insertion point. Below you'll see the most common designs used.

To keep this simple, the design with pointed ends, i.e., the cone/triangular option shown above, has an insertion point smaller than the hole it will be inserted into, making it easier to locate and install into the hole.

The blunt/flat end option will likely be close in size to the hole and will need to be spot on with Installation. In a lot of automotive applications, manufacturers typically choose the pointed option.

Moldability of Fir Tree Designs:

Designing for moldability will play a crucial factor in the success of new designs, including fir-tree clips and fasteners. A few areas injection molders need to focus on include:

- Thin Areas: If the fins or the top skirt areas are too thin, there may be concerns about material flow hesitation, short shots, and potential damage to the parts during the demolding process.

- Fin Style Design: In some cases, such as the curved design shown in fir-tree C above, it may be more challenging to tool up, as well as have the potential to slow down production due to difficulties with the ejection process.

- Material Moldability: A common material used in molding fasteners is nylon. When molding nylon fasteners, we factor in shrinkage, gassing, and moisture's impact on nylon.

Conclusion

In the end, injection-molded fir tree designs offer several advantages over traditional fastening methods. The different fin styles and insertion point designs offer versatility and can be tailored to specific needs. However, careful attention must be paid to moldability factors such as thin areas, fin-style design, material, and tooling. With proper design and implementation, fir tree fasteners can be an effective and efficient solution for various industries and applications.