Advanced Masking: Understanding Platinum Cured vs. Peroxide Cured Silicone

-

By

Lee Lechner

By

Lee Lechner - Apr 21, 2021

When you work as a masking supplier for the top automotive, heavy machinery, and motorsport manufacturers around the world, your knowledge of what works and what doesn't isn't about whether you should choose a cap or a plug. It's much MUCH more than that.

In our advanced masking series, we're going to take you through some of the intricate details that go through our engineering process to develop effective molded masking components that reduce the time it takes to coat and finish components on your manufacturing line.

That said, this post was created to explain what you and your masking solutions provider (like Echo Engineering), need to know when determining what silicone to go with for your application. To do that, let evaluate the pros, cons, and when specifically you should choose either one

What is Curing and Post-Curing?

When it comes to rubber, curing is essentially the process of hardening the material. When it comes to Silicone, platinum-curing and peroxide curing systems are the two primary ways of curing the material.

Post-curing is when the silicone is heated in an oven at a higher temperature for a specific amount of time. In regards to molded silicone masking, post-curing is extremely vital.

Note: Condensation cure systems and oxime cure systems are two other ways of curing silicone, but we will not be discussing those in this post.

What Happens If You Use Uncured Silicone for Masking Application?

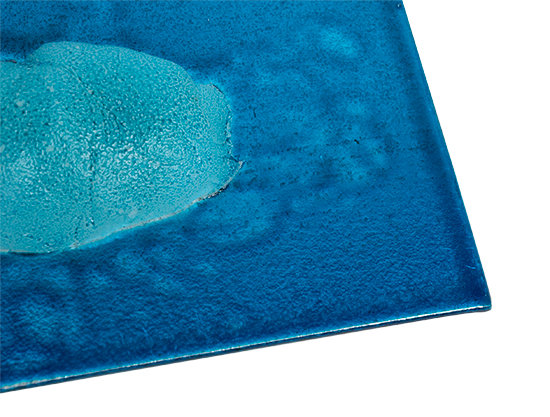

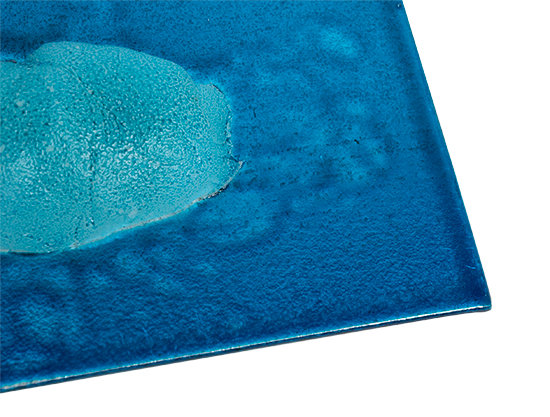

Of course, we had to test this out. Check out the image on the right. We took that same block of uncured silicone from above and placed it on a clean metal sheet. We then powder coated it and baked it in an oven 400F for 20 minutes.

Here was the result (see image). That is what people fear! Because we put a block of uncured silicone through the oven, the high temperatures are causing the silicone to release volatiles onto the metal substrate and powder, which can be seen in the coating imperfections. This is also why many coaters refer to it as silicone residue.

But no need to worry. We're now going to take you through what it takes to reduce/prevent this from happening when it comes to masking applications.

Platinum-Cured Silicone

Platinum cured silicone, also referred to as addition cure silicone, is made using a system where a hydride- and a vinyl-function siloxane polymer react in the presence of a complex platinum catalyst. Put simply, the two polymers combine to form a larger one using the presence of platinum to form a bridge between the two.

Note: A catalyst is a substance that increases the rate of a chemical reaction without itself undergoing any permanent chemical change.

A platinum-catalyzed system is made up of two silicone elastomer base parts, both of equal weight. One part contains the platinum catalyst and the other part contains the crosslinker.

Using platinum catalyst eliminates residual peroxide and peroxide by-products, as it stays embedded in the rubber without forming any volatile compounds. The only volatile organic compounds that are found in platinum are derived from the degradation of carbon-based side groups on the siloxane chains. In order to pass strict requirements that you may find in the automotive and medical industries, platinum compounds will still require a thorough post-cure to remove or lower the overall volatile content in the silicone.

Pros

- Better tensile and tear strength properties

- Has no by-products, making them more favorable for medical and automotive manufacturers

Cons

- HIgher Price: Catalyst costs are higher than peroxide cure systems, which will most likely be reflected in the masking component's price

- Harder to process due to high-temperature cure requirements

When To Choose Platinum-Cured Silicone for Masking Applications

- Automotive and Medical component coating applications

- Because of the higher tear strength, platinum-cured silicone is a great option for oversized pull plugs that have a tighter seal as it will help prevent the plug from tearing during removal

Peroxide-Cured Silicone

Peroxide-cured systems (sometimes referred to as free radical-cured systems), utilize free radicals generated by organic peroxide to decompose at elevated temperatures, initiating a crosslinking reaction.

The issue you'll typically hear about peroxide curing is that it can result in byproducts, such as volatile organic compounds (VOCs). Residual peroxide and peroxide by-products are what form the majority of that VOC content.

When it comes to masking, companies like Echo Engineering will use a high-heat post-curing system to accelerate and remove residue, odor, and toxins, as well as improve the characteristics of the material. It's also necessary to prevent acidic-catalyzed decomposition of the rubber (source).

Pros

- Price: Raw ingredients are typically going to be cheaper, making this process more common due to lower costs

- Longer shelf life

Cons

- Offers less control over cure rates and crosslink distribution, resulting in less consistency in appearance (compared to platinum-cured)

- Higher surface tack, resulting in dirt/dust pick-up (depending on the environment)

- Post cure of four+ hours required to remove cure system residuals

- Silicone masks may have "bloom" (a result of 4-dichlorobenzoic acid accumulating on the surface as a white powder). It will be reduced by post-curing though

When To Choose Peroxide-Cured Silicone for Masking Applications

- Majority of masking projects

- Jobs where cost-reduction is a major factor

Conclusion

As we stated earlier, masking isn't just about choosing a cap or plug. It's designing, engineering, material selection, chemistry, quality control, and much more. If you're working in an industry with stringent regulations, you're going to need to ensure your masking provider understands your requirements.

When it comes to silicone, we get it. Most companies try to avoid it because it's always been that way. This is a result of years and years of misinformation. Silicone is the top option for masking during high-temperature coating processes as it's one of the very few materials that can produce an effective seal and withstand extreme temperatures.

To learn more about silicone masking, set up a time to talk with our experts!