Masking Experiments: Powder Build-Up Around Caps

-

By

Lee Lechner

By

Lee Lechner - Jun 7, 2023

Welcome to the first installment of our new masking experiment series! In this post, we will be taking you through a common problem powder coaters deal with and an experiment we ran in an attempt to prevent the issue without the need for custom masking. So, without further ado, let's get into it!

Problem: Powder Build-Up Around Masking Cap Base

Powder coaters using silicone caps and plugs tend to run into issues with powder building up, resulting in an undesirable paint finish. Powder build-up, referred to as "bridging," can cause problems with tolerance, paint flaking, and increased rejected parts. For high-volume coaters, you'll typically need to go down the route of a custom solution that involves a flange, but what about those scenarios where timing is an issue and you don't have a budget for a custom solution? That's why we've decided to test out a different option.

The Experiment: Cap Raised vs. Flush Against Surface

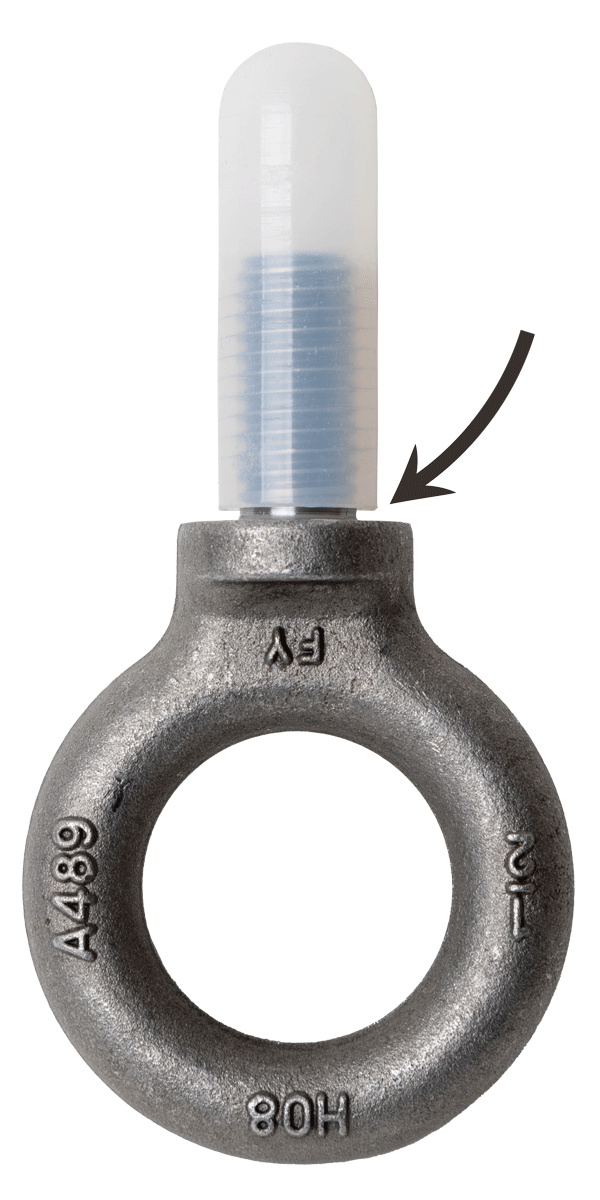

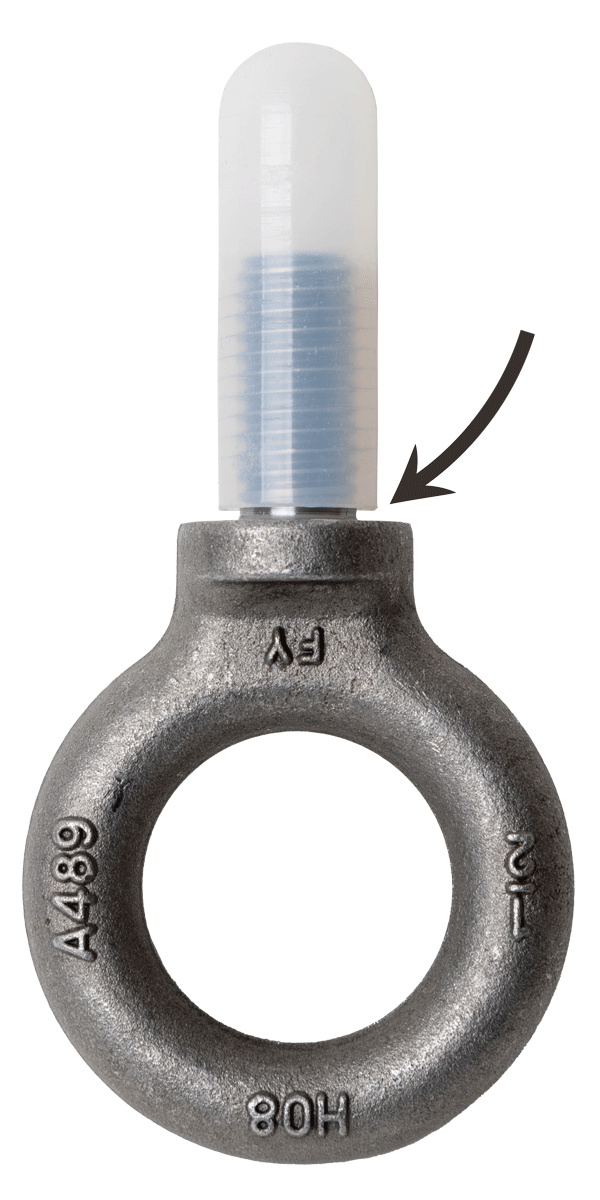

When it comes to masking caps, we thought, why not move the cap up slightly? The theory here is that the powder would hopefully taper down and use the *Faraday effect to its advantage, ultimately preventing any risk of paint build-up. For the experiment, we used two 1/2" eye bolts where we masked off the threads using silicone masking caps.

(Reference images below) On one of the bolts, we pushed the silicone cap flush against the surface to compare the results of the other bolt, where we lifted the cap just slightly above the surface (approximately 2-3mm).

*The Faraday Cage Effect in powder coating happens when the resistance of electrical forces is much greater than on all other surfaces and typically occurs in hollow areas and angles where powder doesn't settle.

Cap Flush Against Surface

Cap Raised 2-3mm Above Surface

Results

After powder coating and curing both parts, as we initially expected, the bolt where the cap was flush against the surface had a slight amount of bridging, as seen in the image below.

The bolt, where the cap was raised approximately 2-3mm above the surface, had no paint buildup because the powder tapered down rather than building up on the cap. With that said, if you look closer at the surface, you'll notice an inconsistent finish of where the powder got underneath the cap. Using this method will result in uneven lines, but with trial and error, you may be able to improve your results compared to our application!

Cap Flush Against Surface Result

Cap Raised 2-3mm Above Surface Result

What Is The Best Method of Preventing Powder Buildup / Bridging?

If you're dealing with a high-volume project and tolerances and production output are critical, then there is a more effective way to reduce and even prevent paint buildups from happening. You can learn more in our How To Reduce Paint Build-Up During Powder Coating blog post, but one of the best methods our engineers have found is by implementing a flange wrapped around at an angle like an umbrella or a skirt. See the graphic below: